|

Engine specifications

|

| Description |

John Deere PowerTech 4045 PWL |

| Engine family |

NJDXL04.5315 |

| Aspiration |

Turbocharged and Aftercooled |

| Cylinders liners |

Wet sleeved |

| Displacement |

4 cylinders: 4.5 L

276 cu in. |

|

Engine performance

|

| Rated power |

At 2400 rpm: 67.1 kW

90 hp |

| Rated PTO power (hp SAE) |

At 2400 rpm: 56.0 kW

75 hp |

|

Front axle

|

| Type |

Mechanical Front Wheel Drive (MFWD) |

|

Transmission

|

| Reverser |

Yes |

| Clutch; wet/dry |

Wet |

| Creeper |

Not available |

|

Hydraulic system

|

| Pump rated output |

85.1 L/min

22.5 gpm |

| Available flow at a single rear SCV |

60.1 L/min

15.9 gpm |

| Number of rear selective controls valves (SCVs) |

2; up to 3 |

| Number of mid selective controls valves (SCVs) |

2; up to 3 |

| Joystick SCV control |

Mechanical |

|

Rear hitch

|

| Hitch draft control load sense type |

Mechanical |

| Remote control valves available |

Standard: Two

Optional: Three |

| Hitch category (SAE designation) |

Category 2; convertible to 1 |

| Maximum lift capacity behind lift points |

Standard: 2100 kg

4600 lb |

| Sensing type |

Top link |

|

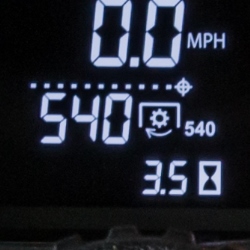

Rear power take-off (PTO)

|

| Engine rpm (at rated PTO speeds) |

540 at 2400 rpm

540E at 1716 rpm

1000 at 2400 rpm |

| PTO actuation |

Electrohydraulic |

|

Rear axle

|

| Differential controls |

Mechanical (pedal) |

| Axle type |

Flanged |

| Brakes, type and control |

Hydraulic wet disc |

|

Tires

|

| Front |

MFWD: 11.2-24 R1 Bias |

| Rear |

MFWD: 18.4-30 R1 Bias |

| Wheel tread range |

MFWD: front: 1340-1904 mm

52.8-75.0 in. |

| Turning radius with brakes |

MFWD: 4.36 m

14.3 ft |

| Turning radius without brakes |

MFWD: 3.54 m

11.6 ft |

|

Operator station

|

| Rollover protective structure, OOS |

Rigid - foldable - telescopic

Foldable, two-post

Platform - flat/straddle

Straddle

Gearshift location - console/floor

Floor

|

| dB(A) rating |

78 dBA |

|

Dimensions

|

| Wheelbase |

2350 mm

92.5 in. |

| Approximate shipping weight, Open;Cab |

OOS: 3300 kg

7275 lb

Cab: 3700 kg

8150 lb |

|

Capacities

|

| Fuel tank |

OOS: 94.6 L

25 U.S. gal.

Cab: 114 L/min

30 U.S. gal. |

|

Key Specs

|

| Engine description |

John Deere PowerTech™ 4045 PWL |

| Engine displacement |

4 cylinders: 4.5 L

276 cu in. |

| Rated engine power |

At 2400 rpm: 67.1 kW

90 hp |

| Transmission type |

Standard: PowrReverser™ 12F/12R

Optional: PowrReverser™ Hi-Lo 24F/12R |

| Hydraulic system type |

Open center |

| Hydraulic pump rated output |

85.1 L/min

22.5 gpm |

| Rear hitch category (SAE designation) |

Category 2 |

|

Hydraulic system

|

| Number of rear selective control valves (SCVs) |

Standard: Two

Optional: Three |

| Number of mid selective control valves (SCVs) |

Standard: Zero

Optional: Up to Three |

|

Dimensions

|

| Approximate shipping wheight, Open;Cab |

MFWD: Open: 3300 kg

7275 lb

Cab: 3700 kg

8150 lb |

|

Weight

|

| Base machine weight |

OOS: 3200 kg (7,055 lb)

Cab: 3600 kg (7,937 lb) |

|

Electrical system

|

| Type of bulb in beacon (Halogen, Zenon, LED) |

Kit: Halogen |

| Type of bulb in headlight (Halogen, Zenon, LED) |

Halogen |

|

Miscellaneous

|

| Country of manufacture |

Saltillo, Mexico |

|

Operator station

|

| Seat |

Standard: Mechanical

Optional for Cab: Air Ride |

|

Capacities

|

| Cooling system |

|

|

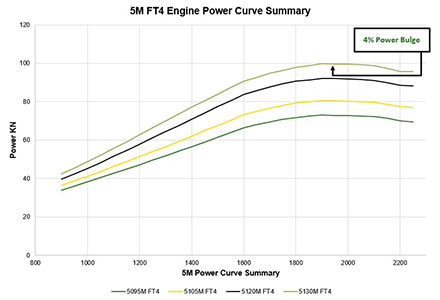

Engine performance

|

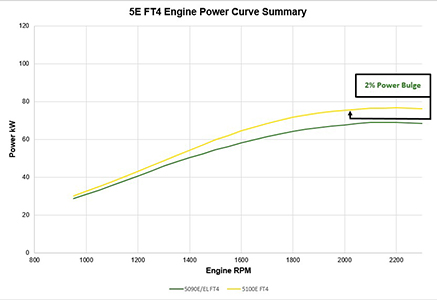

| Maximum engine power |

68.6 kW

92 hp |

|

Engine specifications

|

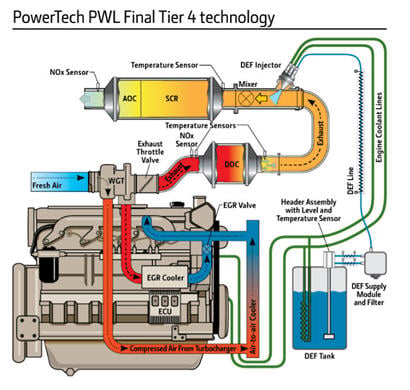

| Engine type |

4045HLV76 |

| Rated speed |

2400 rpm |

| Emission level |

Final Tier 4 |

| After treatment type |

DOC/SCR |

|

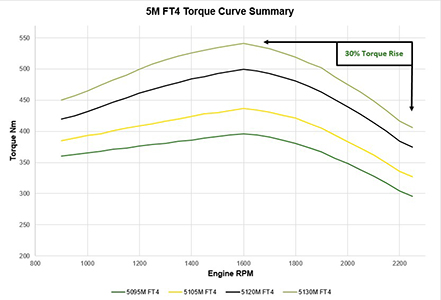

Engine performance

|

| Power boost |

At 2200 rpm: 2 percent |

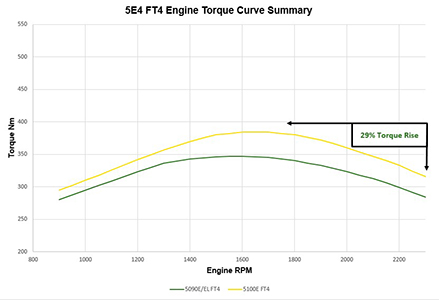

| Engine peak torque |

At 1600 rpm: 347 Nm

255 lb-ft |

|

Drawbar

|

| Drawbar category |

Category 2 |

| Maximum vertical load |

Road/field use (250-mm extended): 1450 kg

3197 lb

Field use (350-mm extended): 1200 kg

2646 lb

Field use (400-mm extended): 1200 kg |

|

Rear axle

|

| Final drive type |

Inboard planetary |

|

Electrical system

|

| Alternator size |

OOS: 90 amp

Cab: 120 amp |

| Battery options |

12 V |

| Working lights |

Halogen |

|

Operator station

|

| Instructional seat |

Optional for Standard cab

Included with Premium cab |

| Display |

Automotive-style light-emitting diode (LED) instrument cluster |

|

Dimensions

|

| Overall length |

4042 mm

159.13 in. |

|

Capacities

|

| Diesel exhaust fluid (DEF) tank |

12.0 L

3.17 U.S. gal. |

|

Miscellaneous

|

| AutoTrac ready |

No |

| ISOBUS ready |

No |

|

Operator station

|

| Inner cab volume |

78 dBA |

|

Precision AG

|

| Guidance |

No |

| Telematic |

JDLink™ |