Nine forward and three reverse speeds with in-line synchronized shuttle shifting

The SyncShuttle transmission is designed to match the excellent power and torque characteristics of the John Deere PowerTech© engines. Transmission durability is enhanced with the pressure-lubricated top shaft, allowing an operator to achieve performance from one working season to the next. Additionally, this in-base transmission is configured with fixed draft links, single-speed power take-off (PTO) and mechanical PTO engagement.

The transmission is characterized as full top shaft synchronized (TSS) when forward shifting on-the-go between speeds, and is characterized a synchronized while depressing the clutch.

| 2100 engine rpm |

| |

|

16.9-28 |

| |

Tire |

0.671 RR |

| Gear |

Rear Wheel Speed |

Ground Speed |

| |

rpm |

kmph |

| A1 |

9.1 |

2.3 |

| A2 |

12.4 |

3.1 |

| A3 |

17.0 |

4.3 |

| A Rev |

-13.5 |

-3.4 |

| B1 |

23.1 |

5.8 |

| B2 |

31.4 |

7.9 |

| B3 |

43.2 |

10.9 |

| B Rev |

-34.2 |

-8.6 |

| C1 |

58.9 |

14.9 |

| C2 |

80.3 |

20.3 |

| C3 |

110.3 |

27.9 |

| C Rev |

-87.3 |

-22.1 |

Creeper available for R2 and R4 as field installed kit with following speeds in kmph.

| Creeper 1 |

0.40 |

| Creeper 2 |

0.54 |

| Creeper 3 |

0.75 |

| Creeper Rev |

-0.59 |

Easy and comfortable shifting

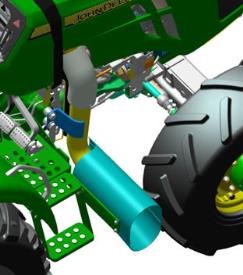

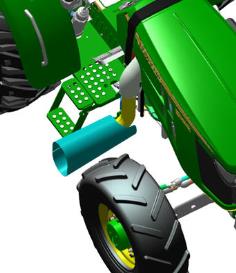

Operator-friendly transmission controls with hand throttle

Operator-friendly transmission controls with hand throttle

Synchronized shifting in all forward and reverse gears

Synchronized shifting in all forward and reverse gears

Range selection pattern

Range selection pattern

Nine forward and three reverse (9F/3R) speeds are achieved by using two platform-mounted levers for shift operation. The gear lever at the operator's right hand selects one of three forward gears and one reverse gear, as well as the integrated park position. The range lever at the operator's left hand selects collar-shift A, B, and C ranges.

Operators can easily switch directions without having to completely stop the tractor with synchronized, in-line, shuttle-shift capability between forward and reverse gears on the gear-shift lever in all three ranges (A, B, and C ranges).

A neutral start switch requires the gear-shift lever be in the neutral or park positions to start the engine.

A positive park pawl on the transmission provides positive park and eliminates the need for a hand brake. This also eliminates clutch service costs that occur when the park brake is accidentally left engaged.