Feature Overview

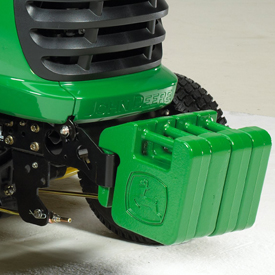

John Deere X370

- 21.5-hp (16.0-kW)* iTorque™ Power System

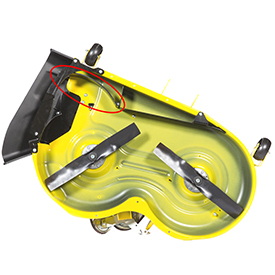

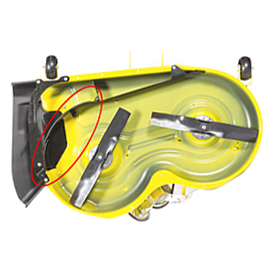

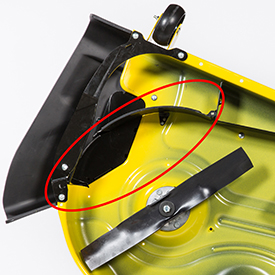

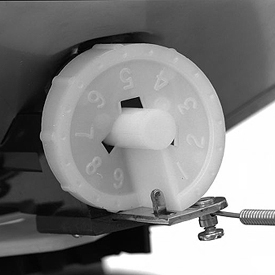

- 42-in. (107 cm) Accel Deep™ mower deck, compatible with optional MulchControl™ kit with one-touch technology

- Power two-wheel steer

- 4 year/300 hour bumper-to-bumper warranty

| Engine power | 21.5 hp / 16.0 kW |

| Engine manufacturer/model | FR651V |

| Transaxle type | K57 hydrostatic integrated with transaxle |

| Transaxle control | Twin Touch™ pedals |

Feature Overview

John Deere X370

- 21.5-hp (16.0-kW)* iTorque™ Power System

- 42-in. (107 cm) Accel Deep™ mower deck, compatible with optional MulchControl™ kit with one-touch technology

- Power two-wheel steer

- 4 year/300 hour bumper-to-bumper warranty

| Engine power | 21.5 hp / 16.0 kW |

| Engine manufacturer/model | FR651V |

| Transaxle type | K57 hydrostatic integrated with transaxle |

| Transaxle control | Twin Touch™ pedals |

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories