Bumper-to-bumper warranty

Model |

Warranty |

W36M, W48M |

24 months no hour limitation |

W36R, W48R, W52R, and W61R |

36 months or 1200 hours, whichever comes first First 24 months, no hour limitation |

John Deere warranty includes:

- Single source

- Commercial application

All parts, except tires and batteries (which are warranted under separate documents provided with each product), are warranted

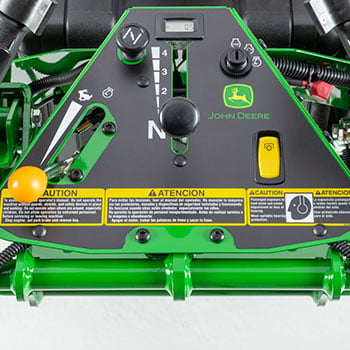

Quick response (QR) codes link to owner information web pages

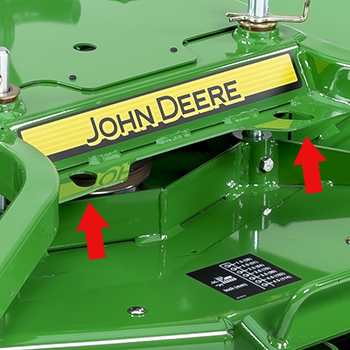

QR code label on M-Series frame

QR code label on M-Series frame

QR code label near R-Series handlebars

QR code label near R-Series handlebars

To speed access to owner information web pages, a QR code is printed onto a product identification number (PIN) label located on frame (M-Series) or near handlebars (R-Series). The owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalogs

- Maintenance reminder sheets

- Attachments

- Warranty statements

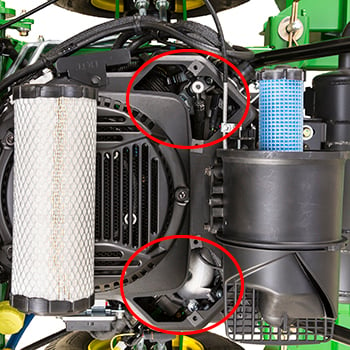

Engine service

Engine service points, W48R engine shown

Engine service points, W48R engine shown

Engine cleanout port cover removed, W48R shown

Engine cleanout port cover removed, W48R shown

Engine service points are easy to reach:

- Oil drain tubes are provided to reduce oil spills and mess.

- Cleanout ports make inspecting and cleaning engine cooling fins easy.

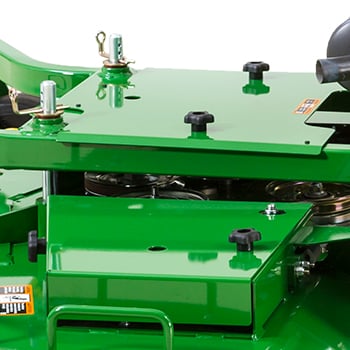

Durable and adjustable control linkage

Control rods with adjustable ends

Control rods with adjustable ends

Plated and adjustable control rods and ends

Plated and adjustable control rods and ends

Control rods and ends are plated to stop rust and corrosion:

- Large pivot points for minimal wear and long life

- Grease fittings to lubricate for continued smooth operation

- Adjustable rod ends for easy and accurate adjustments

Control linkage protected when nesting equipment

Control linkage protected when nesting equipment

Control linkages are positioned tightly to the main frame structure to protect them from damage, such as being bent that could impact the speed and tracking of the unit.

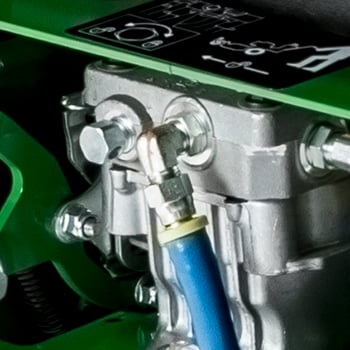

Transmission service

Transmission oil reservoir, W36M shown

Transmission oil reservoir, W36M shown

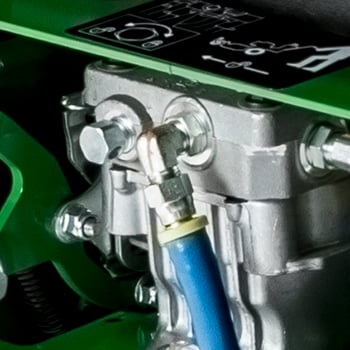

Replaceable transmission oil filter, W52R shown

Replaceable transmission oil filter, W52R shown

Transmission oil reservoirs are easy to access and fill.

The transmission oil filter is a replaceable spin-on type for easy service.

Tow release

Transmission tow-release, M Series design

Transmission tow-release, M Series design

Hydraulic bypass valve, R Series design

Hydraulic bypass valve, R Series design

Transmission tow valves are easy to find and use.

Convenient tie-down locations

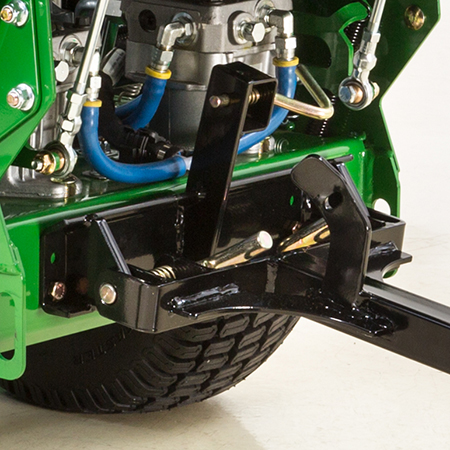

Front tie-down points

Front tie-down points

Rear tie-down points

Rear tie-down points

- Front and rear tie-down points are provided to aid in transport.

- More-rounded corners contribute to a clean, attractive appearance.

- Greater strength results from eliminating sharp angles where peak loads can cause failure.