Bedknife, 6.3 mm with Hardened Insert, Less Aggressive for 66 cm (26-in.) QA7 Cutting Units - TCU34070

Bedknife, 6.3 mm Tournament for 76.2 cm (30-in.) QA7 Cutting Units - UC11472

Bedknife, 6.3 mm Tournament for 66 cm (26-in.) QA7 Cutting Units - MT6949

Bedknife, 15.8 mm Standard for 76.2 cm (30-in.) QA7 Cutting Units - MT1973

Bedknife, 15.8 mm Standard for 66 cm (26-in.) QA7 Cutting Units - ET17752

(1) QA7 Eight Blade 30 In. Cutting Unit - BM24126

(1) Quick-Adjust 7 (QA7) 8-Blade 762-mm (30-in.) Cutting Unit with 15.8 mm bedknife - BM24126

(1) Quick-Adjust 7 (QA7) 8-Blade 660.4-mm (26-in.) Cutting Unit with 6.3-mm bedknife - BM24124

(1) Quick-Adjust 7 (QA7) 660.4 mm (26-in.) Vertical Cutting Unit with Front and Rear Rollers - BUC10072

(1) Quick-Adjust 7 (QA7) 5-Blade 762-mm (30-in.) Cutting Unit with 15.8 mm bedknife - BM24125

(1) Quick-Adjust 7 (QA7) 5-Blade 660.4-mm (26-in.) Cutting Unit with 6.3-mm bedknife - BM24123

(1) Quick-Adjust 7 (QA7) 10-Blade 660.4 mm (26-in.) Cutting Unit with 6.3 mm bedknife - BUC10070

(1) QA7 Five Blade 30 In. Cutting Unit - BM24125

(1) QA7 Five Blade 26 In. Cutting Unit with 6.3mm bedknife - BM24123

(1) QA7 Eight Blade 26 In. Cutting Unit with 6.3mm bedknife - BM24124

Fairway Tender Conditioner

(1) Fairway Tender Conditioner Gear Drive for QA7 Cutting Units - BTC10759

(1) FTC / GTC / Rotary Brush Upgrade Kit - BUC10283

Mounting Hardware for 660.4 mm (26-in.) Grass Catcher - BM22760

Grass Catcher Orifice - BM18185

(1) 660.4-mm (26-in.) Grass Catcher for QA7 Cutting Units - BM22759

30 In. Smooth Roller Scrapers (Set of 3) - BM18440

Smooth roller scraper

Smooth roller scraperScrapers can be installed on rear rollers and smooth front rollers.

- Help keep rollers clean to maintain a consistent height of cut.

(1) 26 In Grass Catcher (3 needed for complete machine) - BM22759

(1) 26 In. 3 In. Diameter Heavy Duty Grooved Roller Scraper - BM23005

(1) Conversion Mounting Kit old Machine to New QA7 Cutting Units - BM22763

(1) QA7 26 In. Fairway Tender Conditioners Shaft and Blades - BM22672

Overall view of FTC

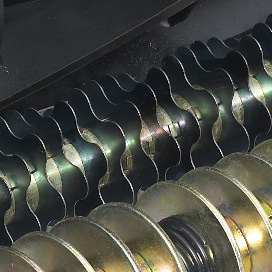

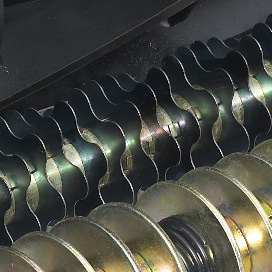

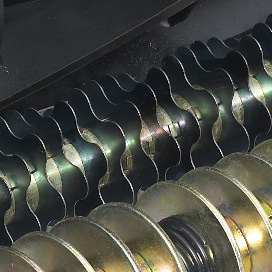

Overall view of FTC FTC blades

FTC bladesThe FTC for the Quick-Adjust 7 (QA7) cutting unit is gear driven and counter-rotates to the direction of the reel to stand up grass, for a premium quality of cut.

The counter-rotating blades eliminate clumping by recycling grass clippings for a smooth, clean playing surface. They also groom the turf by slicing stolons on lateral growing grasses, stimulating the plants and promoting new vertical growth.

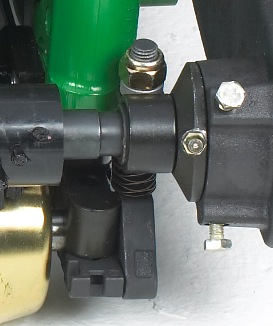

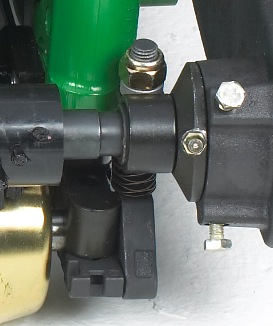

FTC gearcase

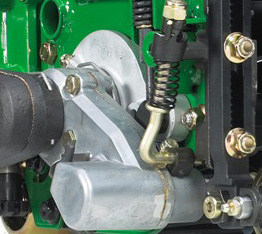

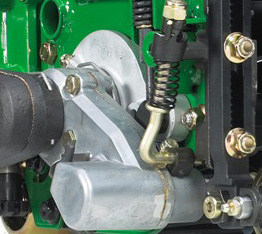

FTC gearcase Clip-mounting system

Clip-mounting systemThe FTC case is mounted using a simple clip system for quick and easy installation. The gearcase can be used on either side of the cutting unit, meaning the same gearcase is used to drive an FTC driven from the left-hand side of the cutting unit or the right-hand side.

When FTCs are installed with rear roller power brushes, the cutting unit is perfectly balanced by the weight of the rear roller power brush housing. The cutting units can also be perfectly balanced due to a weight system that allows use of the proper counterweight based on the cutting unit width if FTCs are installed without rear roller power brushes.

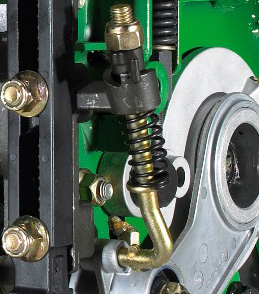

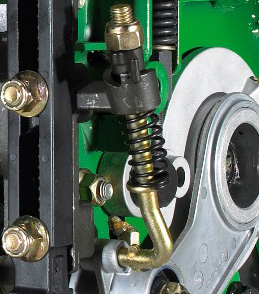

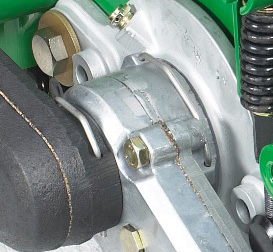

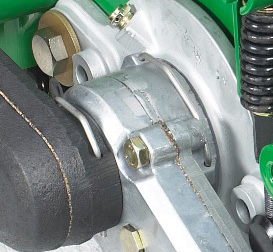

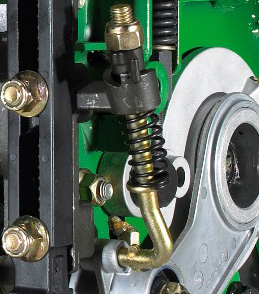

FTC adjuster tower

FTC adjuster towerThe FTCs can be adjusted quickly by using a 0.63-in. (16-mm) wrench or socket to turn a locknut on top of the FTC tower. Turn the locknut clockwise to raise the FTC and counterclockwise to lower the FTC. Each full turn of the locknut changes the FTC height by 0.010 in. (0.254 mm). The system is spring loaded with the spring pulling the FTC away from the turf for optimum performance.

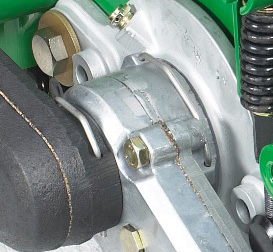

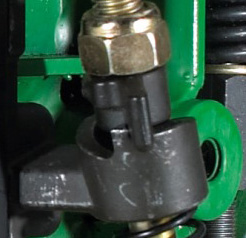

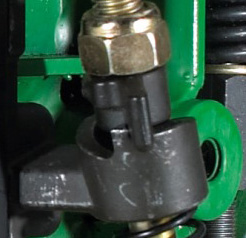

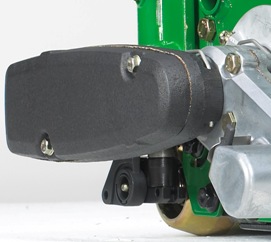

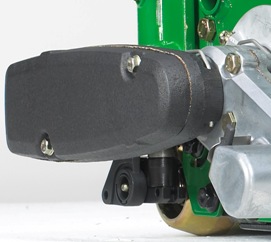

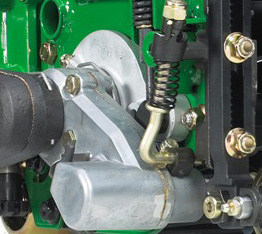

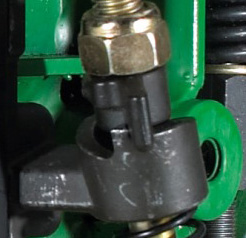

FTC on/off lever

FTC on/off lever FTC engagement ramp

FTC engagement rampDue to the gear drive system, the FTC can be turned on or off by rotating a black lever on the side of the gearcase. For times when conditioning the turf is not desired, the FTC can also be moved to a higher height with a T-handle and ramp system.

Turn the T-handle up the ramp to raise the FTC and turn down the ramp to lower the FTC into the engaged position. With the FTC in the raised position, a detent at the top of the ramp holds the T-handle and prevents the FTC from moving to the engaged position during use.

Without any tools, the FTC can be rotated into the engaged or disengaged position, or the FTC can be turned off or on, providing ultimate flexibility in how the FTC system can be utilized.

(1) QA7 26 In. Rear Roller Power Brush - BM22669

Rear-roller power brush overall

Rear-roller power brush overallTo promote a consistent height of cut, the belt-driven rear-roller power brush prevents debris buildup on the rear roller of the Quick-Adjust 7 (QA7) cutting unit. In some conditions, the rear-roller power brush may also eliminate clumping by evenly distributing grass that may build up on the rear roller. The bristles of the brush are adjusted close to the roller, but do not touch the roller, and rotate when the reel is engaged, deflecting debris off and away from the roller.

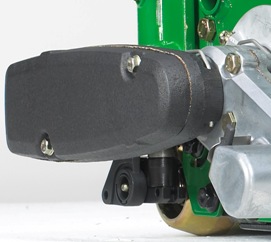

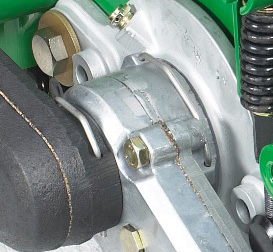

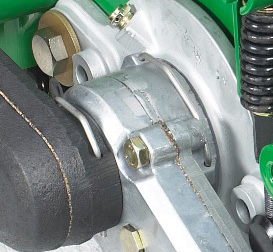

Power-brush clip-mounting system

Power-brush clip-mounting system Belt-drive housing

Belt-drive housingThe housing is easily secured to the cutting unit by a clip system. The same clip is used to secure the power-brush housing to the Greens Tender™ conditioner (GTC) gear case if a GTC is installed, or directly to the cutting unit housing if no GTC is installed. The clip system allows a power brush to be installed on the QA7 cutting unit quickly and easily.

For quiet and reliable operation, the power brush is driven by a cogged belt system. To prevent water and other debris from entering the housing, the housing is also sealed by a gasket to prevent damage to the belt or bearings. An innovative cam design is used to quickly set proper belt tension, and also allows for quick and easy brush removal.

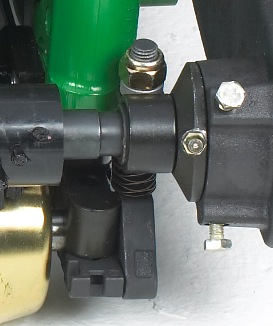

Power-brush adjuster

Power-brush adjusterTo aid in speed while adjusting the brush clearance, the system moves in unison with the rear roller so the brush does not have to be readjusted when the height of cut is changed. Only the wear of the bristles over time need to be adjusted; no other adjustment is required.

Two 0.63-in. (16-mm) locknuts on each end of the brush system serve as the adjusting point to set the clearance between the brush and rear roller quickly. All it takes is a 0.63-in. (16-mm) wrench or socket to complete the adjustment. Turn the locknuts counter-clockwise to move the brush away from the roller and clockwise to move the brush closer to the roller.

(1) QA7 26 In. Rear Roller Power Brush Drive - BM22674

Rear-roller power brush overall

Rear-roller power brush overallTo promote a consistent height of cut, the belt-driven rear-roller power brush prevents debris buildup on the rear roller of the Quick-Adjust 7 (QA7) cutting unit. In some conditions, the rear-roller power brush may also eliminate clumping by evenly distributing grass that may build up on the rear roller. The bristles of the brush are adjusted close to the roller, but do not touch the roller, and rotate when the reel is engaged, deflecting debris off and away from the roller.

Power-brush clip-mounting system

Power-brush clip-mounting system Belt-drive housing

Belt-drive housingThe housing is easily secured to the cutting unit by a clip system. The same clip is used to secure the power-brush housing to the Greens Tender™ conditioner (GTC) gear case if a GTC is installed, or directly to the cutting unit housing if no GTC is installed. The clip system allows a power brush to be installed on the QA7 cutting unit quickly and easily.

For quiet and reliable operation, the power brush is driven by a cogged belt system. To prevent water and other debris from entering the housing, the housing is also sealed by a gasket to prevent damage to the belt or bearings. An innovative cam design is used to quickly set proper belt tension, and also allows for quick and easy brush removal.

Power-brush adjuster

Power-brush adjusterTo aid in speed while adjusting the brush clearance, the system moves in unison with the rear roller so the brush does not have to be readjusted when the height of cut is changed. Only the wear of the bristles over time need to be adjusted; no other adjustment is required.

Two 0.63-in. (16-mm) locknuts on each end of the brush system serve as the adjusting point to set the clearance between the brush and rear roller quickly. All it takes is a 0.63-in. (16-mm) wrench or socket to complete the adjustment. Turn the locknuts counter-clockwise to move the brush away from the roller and clockwise to move the brush closer to the roller.

(1) QA7 FTC Gear Drive - BM22673

Overall view of FTC

Overall view of FTC FTC blades

FTC bladesThe FTC for the Quick-Adjust 7 (QA7) cutting unit is gear driven and counter-rotates to the direction of the reel to stand up grass, for a premium quality of cut.

The counter-rotating blades eliminate clumping by recycling grass clippings for a smooth, clean playing surface. They also groom the turf by slicing stolons on lateral growing grasses, stimulating the plants and promoting new vertical growth.

FTC gearcase

FTC gearcase Clip-mounting system

Clip-mounting systemThe FTC case is mounted using a simple clip system for quick and easy installation. The gearcase can be used on either side of the cutting unit, meaning the same gearcase is used to drive an FTC driven from the left-hand side of the cutting unit or the right-hand side.

When FTCs are installed with rear roller power brushes, the cutting unit is perfectly balanced by the weight of the rear roller power brush housing. The cutting units can also be perfectly balanced due to a weight system that allows use of the proper counterweight based on the cutting unit width if FTCs are installed without rear roller power brushes.

FTC adjuster tower

FTC adjuster towerThe FTCs can be adjusted quickly by using a 0.63-in. (16-mm) wrench or socket to turn a locknut on top of the FTC tower. Turn the locknut clockwise to raise the FTC and counterclockwise to lower the FTC. Each full turn of the locknut changes the FTC height by 0.010 in. (0.254 mm). The system is spring loaded with the spring pulling the FTC away from the turf for optimum performance.

FTC on/off lever

FTC on/off lever FTC engagement ramp

FTC engagement rampDue to the gear drive system, the FTC can be turned on or off by rotating a black lever on the side of the gearcase. For times when conditioning the turf is not desired, the FTC can also be moved to a higher height with a T-handle and ramp system.

Turn the T-handle up the ramp to raise the FTC and turn down the ramp to lower the FTC into the engaged position. With the FTC in the raised position, a detent at the top of the ramp holds the T-handle and prevents the FTC from moving to the engaged position during use.

Without any tools, the FTC can be rotated into the engaged or disengaged position, or the FTC can be turned off or on, providing ultimate flexibility in how the FTC system can be utilized.

1) Conversion Mounting Kit 2009 Machine to Old Cutting ESP Cutting units - BM22764

26 In. Smooth Roller Scrapers (Set of 3) - BM17683

Smooth roller scraper

Smooth roller scraperScrapers can be installed on rear rollers and smooth front rollers.

- Help keep rollers clean to maintain a consistent height of cut.

Attach to standard equipment deluxe seat for additional operator comfort.

Bedknife Hi-Cut, 26-in 15.8 mm - ET17752

Height of Cut Guage Bar - TCU13823

Lift Arms, Front (26 In. Right Hand and Left Hand) - TCB11353

Lift Arms, Front (30 In. Right Hand and Left Hand) - TCB11355

Yokes, Front (30 In. Right Hand and Left Hand) - TCB11373

Yokes, Front (26 In. Right Hand and Left Hand) - TCB11374

Seat, Standard - TCB11106

Seat, Deluxe Suspension with Armrests - TCB11107

Mounting Hardware for 26 In Grass Catcher (set of 3) - BM22760

Light Kit, Front - BM19746

Light kit

Light kit

Light Bracket Kit, Front - TCB11065

Rear Roller Power Brushes

(1) Rear Roller Power Brush Upgrade Kit - BUC10268

(1) Rear Roller Power Brush Drive for QA7 Cutting Units - BTC10768

Reel Cutting Unit Attaching Yokes

(2) Front Lift Arms for 2653B PrecisionCut with 660.4 mm (26-in.) QA7 Cutting Units - TCB11353

(2) Front Lift Arms for 2653B PrecisionCut with 762 mm (30-in.) QA7 Cutting Units - TCB11355

(3) Front Yokes for 660.4 mm (26-in.) QA7 Cutting Units - TCB11374

(3) Front Yokes for 762 mm (30-in.) QA7 Cutting Units - TCB11373

(1) Conversion Mounting Kit 2009 machine to old cutting ESP cutting units - BM22764

(1) Conversion Mounting Kit old machine to new Quick-Adjust 7 (QA7) Cutting Units - BM22763

Reel Cutting Unit Counter Weights

(1) Fairway Tender Conditioner (FTC), Greens Tender Conditioner (GTC), or Rotary Brush ONLY Counter Weight Kit - BM22704

(1) QA7 Rear Roller Power Brush ONLY Counter Weight Kit - BM22721

(1) QA7 Cutting Unit Brush Only Counter Weight Kit - BM22721

(1) Cutting Unit ONLY Counter Weight Kit - BM22762

(1) QA5 FTC/GTC ONLY Counter Weight Kit - BM22704

(1) 660.4 mm (26-in.) Smooth Rear Roller Scraper for Vertical Cutting Units - BUC10110

(1) 660.4 mm (26-in.) x 76.2-mm (3-in.) Diameter Heavy-Duty Grooved Roller Scraper - BM23005

(1) 762 mm (30-in.) x 76.2-mm (3-in.) Diameter Heavy-Duty Grooved Roller Scraper - BM23004

660.4 mm (26-in.) Smooth Roller Scrapers - BM17683

Smooth roller scraper

Smooth roller scraper

Scrapers can be installed on rear rollers and smooth front rollers.

- Help keep rollers clean to maintain a consistent height of cut.

762 mm (30-in.) Smooth Roller Scrapers - BM18440

Smooth roller scraper

Smooth roller scraper

Scrapers can be installed on rear rollers and smooth front rollers.

- Help keep rollers clean to maintain a consistent height of cut.

(1) 660.4-mm (26-in.) x 76.2-mm (3-in.) Diameter Spiral Grooved Roller with Spiral End Caps - BM19818

Spiral-grooved rollers with spiral endcaps

Spiral-grooved rollers with spiral endcaps

The 3-in.-diameter spiral-grooved front roller with spiral endcaps allows more grass to stand up along the entire width of the cutting unit, providing a better quality of cut. This roller is also self-cleaning, reduces material buildup on the ends, and improves the overall appearance of the finished cut.

(1) 660.4 mm (26-in.) Smooth Front Roller Scraper for Vertical Cutting Units - BUC10076

(1) 762 mm (30-in.) x 76.2 mm (3-in.) Diameter Heavy Duty Grooved Disc Roller - BM25319

(1) 762-mm (30-in.) x 76.2-mm (3-in.) Diameter Heavy-Duty Smooth Solid Roller - BM18439

(1) 762-mm (30-in.) x 76.2-mm (3-in.) Diameter Spiral Grooved Roller with Spiral End Caps - BM19819

Spiral-grooved rollers with spiral endcaps

Spiral-grooved rollers with spiral endcaps

The 3-in.-diameter spiral-grooved front roller with spiral endcaps allows more grass to stand up along the entire width of the cutting unit, providing a better quality of cut. This roller is also self-cleaning, reduces material buildup on the ends, and improves the overall appearance of the finished cut.

(1) 26 In. 3 In. (7.6 cm) Diameter Heavy Duty

Grooved Disc Front Roller - BM25318

(1) 660.4 mm (26-in.) x 76.2 mm (3-in.) Diameter Heavy-Duty Smooth Solid Roller - BM17671

(1) 660.4 mm (26-in.) x 76.2 mm (3-in.) Diameter Heavy Duty Grooved Disc Roller - BM25318

(1) 30 In. 3 In. (7.6 cm) Diameter Spiral Grooved

Front Roller With Spiral End Caps - BM19819

Spiral-grooved rollers with spiral endcaps

Spiral-grooved rollers with spiral endcapsThe 3-in.-diameter spiral-grooved front roller with spiral endcaps allows more grass to stand up along the entire width of the cutting unit, providing a better quality of cut. This roller is also self-cleaning, reduces material buildup on the ends, and improves the overall appearance of the finished cut.

(1) 30 In. 3 In. (7.6 cm) Diameter Heavy Duty

Smooth Solid Front Roller - BM18439

(1) 30 In. 3 In. (7.6 cm) Diameter Heavy Duty

Grooved Disc Front Roller - BM25319

(1) 26 In. 3 In. (7.6 cm) Diameter Spiral Grooved

Front Roller With Spiral End Caps - BM19818

Spiral-grooved rollers with spiral endcaps

Spiral-grooved rollers with spiral endcapsThe 3-in.-diameter spiral-grooved front roller with spiral endcaps allows more grass to stand up along the entire width of the cutting unit, providing a better quality of cut. This roller is also self-cleaning, reduces material buildup on the ends, and improves the overall appearance of the finished cut.

(1) 26 In. 3 In. (7.6 cm) Diameter Heavy Duty

Smooth Solid Front Roller - BM17671

Seat, Deluxe Suspension with Armrests - BTC10758

Seat, Standard - BTC10757