Powerful Yanmar engine

Powerful Yanmar engine

The Yanmar diesel engine has a high-torque reserve that provides plenty of power under heavy load.

This 4-cylinder engine features lower levels of exhaust emissions and reduced noise levels. It meets EPA Final Tier 4 (FT4) emission standards.

Model |

Number of

cylinders |

Engine

displacement |

Aspiration |

Rated

rpm |

Gross engine

hp* |

Gross engine ps* |

PTO hp |

4044M/R |

4 |

2.2 L |

Natural |

2600 |

42.5 |

43.1 |

32.5 |

4052M/R |

4 |

2.1 L |

Turbocharged |

2600 |

50.8 |

51.5 |

39.9 |

4066M/R |

4 |

2.1 L |

Turbocharged |

2600 |

65.0 |

65.9 |

52.0 |

*Engine hp (kW), gross SAE J1995: 43.1 (31.7) at 2600 rpm, PS

Displacement, cu in. (L):134.25 (2.2)

*Engine hp (kW), gross SAE J1995: 51.5 (37.9) at 2600 rpm, PS

Displacement, cu in. (L):128.15 (2.1)

*Engine hp (kW), gross SAE J1995: 65.9 (48.5) at 2600 rpm, PS

Displacement, cu in. (L):128.15 (2.1)

The engine uses the latest technologies to optimize fuel economy, improve control and accuracy, and reduce environmental impact.

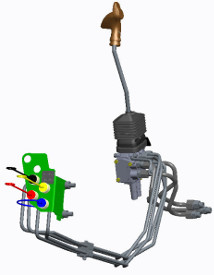

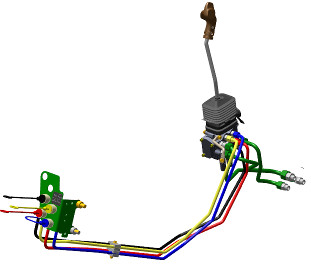

The common rail system (CRS) optimizes fuel economy and reduces operating costs*. High-pressure injection atomizes fuel into finer particles which burn more completely. It results in improved fuel economy and lower cost of operation.

The electronic control unit (ECU) provides optimum fuel control and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery accordingly to ensure optimum performance and emissions.

The new engine comes with an after treatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate matter (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the heat of the exhaust stream generated by normal use. In situations of low temperature, engine speed or load factor, an active cleaning cycle is initiated. In this cleaning cycle, the exhaust gas temperature is raised by injecting additional fuel during the exhaust stroke of normal vehicle operation to the diesel oxidation catalyst (DOC).

After many hours of use, the exhaust filter may require an ash removal service.

NOTE: *As compared to engines not using CRS technology.

DPF cleaning

Depending on the load that the tractor is under, as well as ambient temperature, humidity, and engine speed, the DPF may build up with particulate matter, thus requiring cleaning. Filter cleaning is determined by one of three conditions:

- A prescribed time-based estimation of needed filter cleaning

- DOC/DPF pressure sensors

- A particulate matter buildup estimation based on load conditions

Once one of the three conditions has been met, filter cleaning will occur.

There are three different types of filter cleaning processes:

- Passive filter cleaning

- Active filter cleaning

- Parked filter cleaning

Passive filter cleaning

Passive filter cleaning occurs naturally when the engine is generating enough heat to oxidize particulate matter. This automatic process occurs continuously during normal operating conditions. No tractor icons or symbols appear on the display during passive filter cleaning.

NOTE: Passive filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Active filter cleaning

If conditions (temperature, load, or speed) for passive filter cleaning cannot be achieved, then PM is removed using active filter cleaner.

To achieve the required conditions, exhaust temperature management (ETM) manages the initiation and duration of active filter cleaning. ETM can adjust numerous engine parameters and/or inject a small quantity of fuel into the exhaust stream for a short duration. The fuel turns to vapor and chemically reacts with the catalysts in the DOC to create heat to oxidize PM.

It is important to note that at no time is the fuel in the DOC/DPF ignited, and there is no flame within the DOC/DPF.

Like passive filter cleaning, active filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Parked filter cleaning

In some instances where passive and active filter cleaning have not fully cleaned the PM from the system, a parked filter cleaning may need to take place. Most likely, the only time a parked filter cleaning will need to occur is when automatic filter cleaning has been disabled for an extended period of time and multiple warnings to engage filter cleaning were ignored or if the tractor has been used during light load conditions. Additionally, when the automatic filter cleaning process has been deliberately interrupted multiple times, or if active filter cleaning has failed numerous times due to a failed component, a parked filter cleaning may be requested. In these rare instances the operator will have to park the tractor and start the filter cleaning process.

The parked filter cleaning process needs to be activated based on usage and operation of the tractor. The process will take approximately 30 minutes. See operator’s manual for more details.

This system constantly monitors the soot level of the tractor, making sure the tractor is always in peak performance condition. This ensures high performance at all times.

NOTE: Number of hours since last regeneration and soot level percentage viewable on LCD display.

Key features of the engine are:

- Lower rated speed for 540 rpm power take-off (PTO) operation means better fuel economy, less noise and vibration, and longer overall engine life

- Cast-in-block cylinder design for good cooling and long life

- Hydraulic lifters are quieter and require no adjustment

- Heavy-duty crankshaft provides more bearing surface area for added durability

- CRS optimizes fuel economy, lowering the cost of operation

- ECU provides optimum control and accuracy

- Direct fuel injection

- Improves starting

- Injects fuel directly on top of pistons for more efficient combustion

- Develops more horsepower per gallon of fuel

- Glow plugs (cold starting aid)

- Engine oil cooler, cools engine oil for longer engine life

- Key start and shutoff eliminates fuel shutoff knob

- Electric solenoid shuts fuel supply off immediately when key is turned off

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

- Sealed radiator compartment keeps trash and debris on outside of hood

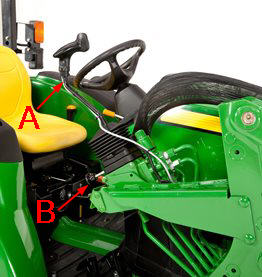

Dry-type air cleaner

Dry-type air cleaner

- Dry-type air cleaner with safety element and electronic air service indicator

- Electronic air restriction indicator alerts operator when air filter servicing is required

- Dual-element design for added engine protection

- Easy to service

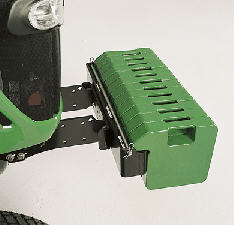

- Standard side exhaust

- Discharges fumes away from the operator, reducing engine noise

- Improves operator visibility when using a loader or front implement

- Optional vertical exhaust

Yanmar is a trademark of Yanmar Company Limited.