Durable, efficient, high-torque 3-cylinder diesel engine provides adequate power

3-cylinder Yanmar TNV Series diesel engine

3-cylinder Yanmar TNV Series diesel engine

Power is provided by a durable and efficient high-torque three-cylinder Yanmar® TNV Series diesel engine.

This series of engines was developed to meet Tier 4 Environmental Protection Agency (EPA) environmental requirements by featuring low levels of both exhaust and emissions.

Model |

Number of

cylinders |

Engine

displacement |

Gross engine power |

Power take-off (PTO) power |

2025R |

3 |

1.267 L |

18 kW (24.2 hp) |

12.8 kW (17.2 hp) |

Yanmar TNV Series engine offers these features:

- Economical for good cooling and long life

- Isolated engine provides reduced vibration and noise for the operator; indirect fuel injection uses a precombustion chamber to give the engine a smooth and quiet operation; aluminum-alloy piston with built-in steel struts are lightweight to reduce connection rod bearing loads and provide good heat transfer characteristics

- Design permits tighter tolerances and neutralizes expansion of the piston, thereby reducing blow-by gas and less noise from the piston slap

- Higher top rings on the piston and a thinner head gasket greatly reduces the volume of unburned waste gases and increases combustion efficiency

- Timing-gear teeth have a designed roll-off profile giving almost no clash, no noise, and no backlash

- High-torque reserve provides plenty of power under heavy load, yet retains excellent fuel economy

- Easy access to engine check and fill points on the right-hand side of the tractor by removing the side panels

- Fuel filter with replaceable element

- Full-pressure lubrication system provides filtered oil under pressure to all vital engine parts

- Glow plugs provide quick starts in temperatures down to -18°C (0°F) (Optional engine coolant heater attachment will assist starting under more extreme conditions.)

- Auto-bleed fuel system means there is no special bleeding required if the tractor runs out of fuel; this system will self-prime the injection pump, lines, and injectors, providing fast fuel recovery

- Key start and shut off eliminates fuel shut-off knob

- Electric solenoid shuts fuel supply off immediately when key is turned off

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

- Dry-type air cleaner with safety element keeps dirt and other contaminants out of the engine

- Safety element (second filter) will protect engine if primary filter would develop a leak

- Protects engine when servicing primary filter

- Air filter restriction indicator is standard equipment on the 2025R Tractor

- Sealed-radiator compartment keeps trash and debris on outside of hood

- Horizontal exhaust discharges fumes away from the operator station, reducing noise and improving operator visibility and comfort

Yanmar is a trademark of Yanmar Company Limited.

Easy-to-use hydrostatic transmission (HST) increases efficiency

The 2R Series are equipped with a two-range hydrostatic transmission (HST) incorporated in a die-cast aluminum transmission case. Fluid under pressure transmits engine power to the drive wheels via a closed-loop pump and motor arrangement. Infinite ground speeds allow the operator to match the speed of the tractor to the job.

- No clutching for fast and easy direction changes

- Twin Touch© foot pedals for quick and easy forward/reverse operation

- Transmission oil cooler cools transmission oil for longer transmission life

Safety features of the HST include:

- The tractor will only start with the range lever in neutral

- If the range lever is in gear when the key is turned to the start position, the instrument panel instructs the operator to shift to neutral

- The engine will shut off if the operator leaves the seat and the forward/reverse pedals are depressed

Twin Touch foot controls

Twin Touch foot controls

Two-range transmission

Two-speed transmission

Two-speed transmission

Transmission has two speeds - hi and lo range.

- The range lever is located next to the seat, conveniently within reach of the operator

- All tasks can be performed using two ranges on the 2025R which means less shifting throughout the day

Durability features include:

- Large forged one-piece trunnion shaft with larger support bearings that reduce vibration and noise

- Innovative transaxle combines an HST, gear reduction axle, and clutch

- Pressure side filtration allows the use of a fine-mesh filter

- One pump to supply charge pressure and implement A flow divider splits the flow to various circuits throughout the tractor.

- The transaxle has an oil cooler which provides improved hydraulic cooling performance

Fast and easy implement changeover offers versatility

Easy to change implements

Easy to change implements

- Front Quik-Tatch© hitch makes changing front implements quick and easy

- All front implements (blades, brooms, and snow blowers) use a common hitch

- AutoConnect© Mid-Mount Mower Deck, 120R Loader, and 260B Backhoe can be taken on or off within 5 minutes, and no tools are required

- Changing rear implements is a snap with the iMatch© Quick-Hitch, which has three fixed points to back in and pick up a rear implement that is iMatch compatible

Implement compounding improves efficiency

Implement compounding (2025R Tractor shown)

Implement compounding (2025R Tractor shown)

Premium independent mower lift system allows quick and easy adjustment

The optional premium independent lift system has been improved over the current 1 Family system by now allowing the operator to have full control of the mower deck in both the raise and lower positions. When the operator reaches the desired height, the button can be released and the deck will hold its position. This feature reduces the effort required to adjust the height-of-cut (HOC) dial and it also allows for quick height changes on the go.

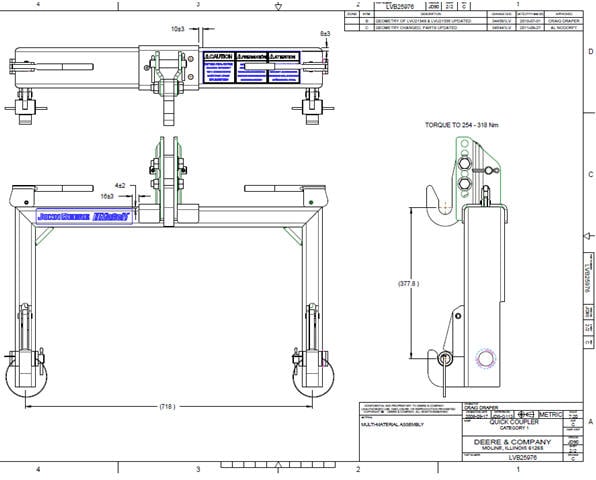

Optional iMatch™ Quick-Hitch feature allows for easy implement hookup

iMatch Quick-Hitch

iMatch Quick-Hitch

iMatch Quick-Hitch with rotary cutter hookup

iMatch Quick-Hitch with rotary cutter hookup

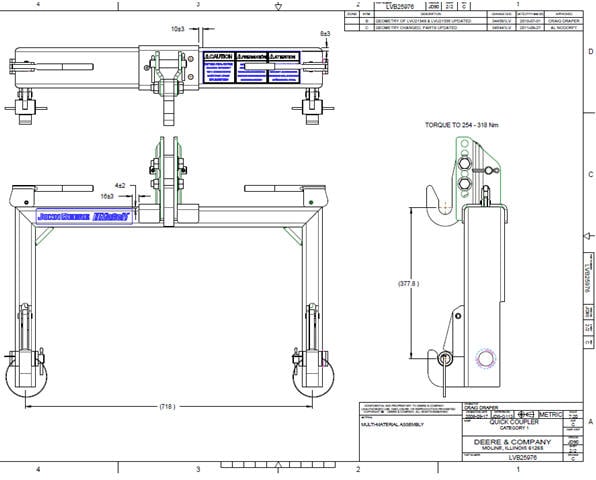

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

One of the greatest operator concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the American Society of Agricultural and Biological Engineers (ASABE) Category 1 Standard S278.6 for quick-attach hitches.

- All implements require a set of bushings in order for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

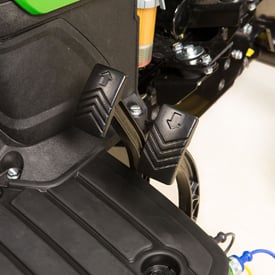

NOTE: The bushing set can be seen in the picture above. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

- Upper bushing

- Inside diameter: 1.93-1.95 cm (0.76-0.77 in.)

- Outside diameter: 3.15-3.18 cm (1.24-1.25 in.)

- Lower bushings

- Inside diameter: 2.24-2.26 cm (0.88 to 0.89 in.)

- Outside diameter: 3.63-3.66 cm (1.43 to 1.44 in.)

Superb serviceability improves productivity

Regular service and maintenance are essential to the performance, productivity, and longevity of the tractor.

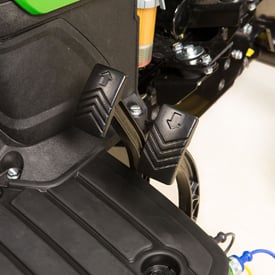

- Two quarter-turn fasteners allow operators to easily remove the engine side panels without tools to access to the engine compartment.

Fasteners on the engine side panels

Fasteners on the engine side panels

- The under-hood gas-lift support provides easy access to the engine compartment and eliminates the need for a mechanical prop rod.

Under-hood gas lift makes it easy to access the engine

Under-hood gas lift makes it easy to access the engine

External hood latch requires no tools and can release using the tractor key.

Easy access to regular service points minimizes service time.

Daily service checks, such as checking the engine oil or water separator, can be done without opening the hood or removing the tractor side panels.

Tractors are equipped with a mechanical air filter restriction indicator that alerts the operator when the air filter needs to be cleaned or changed.

Air filter restriction indicator

Air filter restriction indicator

- All external engine, fuel, and transmission filters are easily accessible.

- Fuel tank is located on the rear of the tractor to allow for easy access when fueling.

Fuel tank at rear of tractor

Fuel tank at rear of tractor

NOTE: Always refer to the operator’s manual for complete maintenance and service recommendations.

Factory-installed mechanical mower deck lift components reduces dealer initial mower deck install

2025R Tractor

2025R Tractor

- The 2025R model includes factory-installed mechanical deck lift components.

- The addition of these components from the factory significantly reduces the time required to do the initial mower deck installation at the time of purchase.

- Refer to the mowers and material collection page for more details on mower deck installation and compatibility.

Increase productivity with optional auto throttle feature

An optional auto throttle kit is available for the 2025R Tractors. This feature is designed to make the tractor quieter and use less fuel. With auto throttle installed, the engine rpm and transmission speed will increase as the Twin Touch© pedals are depressed. This feature can be beneficial for use in many different applications, especially for front loader work and when transporting on roads or in parking lots.

For loader work, producers will get maximum benefit from the system by increasing engine rpm with the hand throttle to at least 50 percent. Once the hand throttle is set, auto throttle will help provide the feeling of a power boost when the producer is filling the bucket with material from a pile. The harder the hydro pedal is pressed, the more engine speed available. In this scenario, as the producer presses the pedal, the engine will operate between 50 percent throttle and 100 percent throttle. It will not go below 50 percent until the hand throttle is lowered back down.

In power take-off (PTO) applications such as mowing or snow blowing, auto throttle is not recommended because PTO implements usually require a constant speed in order to properly function.

Optional cab offers protection from elements

The Mauser cab offers protection from the elements and expands the versatility of 2025R Tractors to perform in all climates.

2025R cab

2025R cab

Key features:

- Full glass doors for maximum visibility

- Curved glass for a styled look

- Sealed for cold weather operation

- Easily removable for summer operation

- Heater with fan

- Switches and vents integrated into headliner

- Dome light

- Fully openable front and rear windows with gas struts

- Front sun visor

Operator view from inside the cab

Operator view from inside the cab

Front work lights

Front work lights

- Front wiper with washer system

- Dual outside mirrors

- Rollover protective structure (ROPS) certified cab frame

- Allows for improved rear visibility

- Reduces overall height

- Rubber isolation at all mounting points

- Interior sound insulation

Interior sound insulation

Interior sound insulation

- Immersion-primed and powder-coated cab frame

- Provides superior corrosion resistance

- Integrated John Deere styling

John Deere styling on 2025R cab

John Deere styling on 2025R cab

Specifications:

- Cab height: 1495 mm (58.9 in.)

- Overall height when installed: 2040 mm (80.3 in.)

- Overall height when installed to top of beacon: 2210 mm (87 in.)

- Overall width with cab installed: same as tractor width

- Cab weight: 236 kg (520 lb)

Optional kits:

- Rotating beacon light ™ BXX10310

- Rear LED work light kit ™ BLV11083

- Mauser cab relocation bracket ™ BXX10507 (used with 1025R and 2025R Tractors with Mauser cab and mechanical-self-leveling [MSL] loaders)

- Prevents interference with Mauser cab and MSL loader mast

Compatibility and installation:

- Compatible with:

- Model year 2017 and newer 2025R Tractors

- Not compatible with:

Key features of the 2025R Tractor

Engine

- Updated isolated Yanmar® TNV Clean & Silent Diesel Engine

- Meets Tier 4-emission standards

- Engine features lower levels of exhaust and emissions

- Isolated engine for quieter operation

- 24.2 gross hp* - 18 PTO hp* (5.8 percent increase in PTO hp over the 4110 Tractor)

* As per 97/68/EC ISO @ rated speed.

Powertrain

- Standard HST transmission with Twin Touch© foot pedals

- Allows for increased performance

- Larger tires

Hydraulics

Operator station and controls

- Ag tractor family styling

- One-piece hood design

- Updated instrument panel, dash, and throttle design

- Molded foot deck

- Standard folding rollover protective structure (ROPS)

- Standard mid rockshaft with mower deck height adjustment

Implements

Standard equipment for the 2025R Tractor

- Folding ROPS

- Dual mid-selective control valve with integrated loader joystick control

- Power steering

- Four-wheel drive

- Mid PTO

- Wet-disk brakes

- Cruise control

Yanmar is a U.S.-registered trademark of Yanmar Company Limited.

Powerful John Deere engine

Powerful John Deere engine

Power is provided by a durable and efficient high-torque 3-cylinder Yanmar TNV Series diesel engine.

Model |

Number of

cylinders |

Engine

displacement |

Gross

engine hp* |

PTO hp* |

2025R HST |

3 |

68.0 (1.267 L) |

24.2 |

18.0 |

2032R HST |

3 |

100 (1.642 L) |

31.7 |

23.5 |

This series of engines was developed to meet environmental requirements for Tier 4 (2025R) emission requirements by featuring lower levels of both exhaust and emissions.

* As per 97/68/EC ISO at rated speed.

Yanmar TNV Series engine offers these features:

- Economical cast-in block cylinder design for good cooling and long life

- Indirect fuel injection on the 2025R uses a pre-combustion chamber to give the engine a smooth and quiet operation

- Direct fuel injection on the 2032R injects fuel on top of the pistons and allows for more efficient combustion and fuel economy

- Aluminum alloy piston with built-in steel struts are lightweight to reduce connection rod bearing loads and provide good heat transfer characteristics

- Design permits tighter tolerances and neutralizes expansion of the piston, thereby reducing blow-by gas and generating less noise from the piston slap

- Higher top rings on the piston and a thinner head gasket greatly reduces the volume of unburned waste gases and increases combustion efficiency

- Timing gear teeth have a roll-off profile giving almost no clash, no noise, and no backlash

- Special flywheel flange seals flywheel air turbulence noise inside the flywheel housing

- High-torque reserve provides plenty of power under heavy load yet retains excellent fuel economy

- Fuel filter with replaceable element

- Full-pressure lubrication system provides filtered oil under pressure to all vital engine parts

- Glow plugs on the 2025R provide quick starts in temperatures down to 0° F. (Optional engine coolant heater attachment will assist starting under more extreme conditions.)

- Air intake heater cold starting aid on the 2032R provides quick starts in temperatures down to

0° F. (Optional engine coolant heater attachment will assist starting under more extreme conditions.)

- Auto-bleeding fuel system means there is no special bleeding required if the tractor runs out of fuel

- This system will self-prime the injection pump, lines, and injectors, providing fast fuel recovery

- Key start and shutoff eliminates fuel shutoff knob

- Electric solenoid shuts fuel supply off immediately when key is turned off

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

Dry-type air cleaner

Dry-type air cleaner

- Dry-type air cleaner (1) with safety element (2) keeps dirt and other contaminants out of the engine

- Safety element (second filter) will protect engine if primary filter would develop a leak

- Protects engine when servicing primary filter

- Air cleaner service indicator is standard equipment on all models and alerts owner as to when to service the air filter

- The one-piece hood can be easily raised for full access to engine compartment

- Front grille screen and sides on one-piece hood provide excellent flow of air to the engine compartment

- Sealed radiator compartment keeps trash and debris on outside of hood

- Improved fuel fill is relocated to right side of hood allows easier refueling

- Horizontal exhaust discharges fumes away from the operator station, reducing noise and improving operator visibility and comfort.

Yanmar is a U.S.-registered trademark of Yanmar Company Limited.

Twin Touch© foot controls

Twin Touch© foot controls

The 2025R and 2032R hydrostatic (HST) Tractors feature a foot-controlled hydrostatic transmission.

-

Low pedal effort makes the transmission very easy to operate

-

Fluid under pressure transmits engine power to the drive wheels through a hydraulic pump and motor

-

The hydrostatic drive unit functions both as a clutch and transmission

Twin Touch foot controls allow selecting both speed and direction of travel with a touch of the toe. Ideally suited for jobs where productivity is a must, such as loader or mower applications.

- Infinite ground speeds, even at full throttle, to match the job

- No clutching for fast direction changes

- Faster, easier, and more precise to operate than competitive tractors with treadle pedal design (toe-heel)

Provides high torque for start up

- Reduces powertrain shock loads

- Large rubber foot pedals were designed for operator comfort and allow for convenient operation of the tractor

Speed range lever

Speed range lever

Transmission has two speeds - hi and lo range.

- The range lever is located next to the left-hand fender (A), conveniently within reach of the operator.

Kanzaki® HST transmission is used for reliable operation.

Durability features include:

1) Large forged one-piece trunnion shaft with larger support bearings that reduce vibration and noise.

2) Innovative transaxle combines an HST transmission, gear reduction axle, and clutch.

3) Pressure side filtration allows using a finer mesh filter (10 micron) than suction filtration systems used on many competitive tractors.

4) Charge pump used to deliver oil to transmission (some competitive tractors use one pump for transmission and hydraulics).

5) Oil cooler cools transmission oil for longer transmission life.

Kanzaki is a U.S.-registered trademark of Kanzaki Kokyukoki Mfg. Company.

Optional iMatch™ Quick-Hitch allows for easy implement hookup

iMatch Quick-Hitch

iMatch Quick-Hitch

iMatch Quick-Hitch with rotary cutter hookup

iMatch Quick-Hitch with rotary cutter hookup

One of the greatest operator concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements designed to meet the ASAE Category 1 Standard S278.6 for quick-attach hitches.

NOTE: In the above picture with the rotary cutter, the bushing set BW15056 is shown. These bushings allow the hooks on the iMatch and the pins on the rotary cutter to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

iMatch Quick-Hitch dimensions

iMatch dimensions

iMatch dimensions

iMatch Quick-Hitch implement geometry

iMatch implement dimensions

iMatch implement dimensions

Easily change power take-off (PTO) driven implements with iMatch™ AutoHitch™ system

iMatch AutoHitch

iMatch AutoHitch

iMatch AutoHitch hookup with rotary cutter

iMatch AutoHitch hookup with rotary cutter

iMatch AutoHitch is the next generation of the successful iMatch Quick-Hitch that allows operators to hook up the PTO shaft of certain PTO-driven implements. This revolutionary system is the first of its kind, allowing the operator to change from a compatible rotary cutter to a compatible rotary tiller without leaving the seat of the tractor.

John Deere continues to lead the way with innovative designs that ensure operators can quickly and easily change implements and attachments on the compact utility tractors with no tools and little experience needed.

|

Engine

|

| Engine power (gross) |

SAE J1995 rated power: 17.8 kW

23.9 hp

24.2 PS at 3200 rpm |

| Power take-off (PTO) power |

12.8 kW

17.2 hp |

|

Key Specs

|

| Steering hydraulics |

13.4 L/min

3.5 gpm |

| Implement hydraulics |

13.4 L/min

3.5 gpm |

| Hitch type |

Limited Category 1 |

|

3-point hitch

|

| Lift capacity, 24-in. behind link arms |

415 kg

915 lb |

|

Transmission

|

| Standard transmission; forward/reverse |

Hydrostatic - two range |

| Cruise control |

Standard |

|

Dimensions

|

| Approximate shipping weight (open-station; cab) |

Open station: 849 kg

1872 lb

Cab: 1085 kg

2392 lb |

| Wheelbase |

1600 mm

63 in. |

|

Engine

|

| Family |

GYDXL1.27NS1

HYDXL1.27NS1 |

| Manufacturer |

Yanmar® |

| Engine model |

3TNV80F-NCJT |

| Rated engine speed |

3200 rpm |

|

Final drive

|

| Type |

Spur gear |

|

Engine

|

| Injection pump type |

Indirect injection |

| Aspiration |

Natural |

| Emissions compliance |

Final Tier 4 |

| Cylinders/displacement |

Three cylinders: 1.267 L

77 cu in. |

| Number of cylinders |

Three |

| Cylinder liners |

Cast-in-block |

| Bore and stroke |

80 x 84 mm

3.2 x 3.3 in. |

| Compression ratio |

23.1:01 |

| Lubrication |

Pressurized |

| Cooling system |

Water pump |

| Air cleaner |

Dual element |

| Engine torque at rated speed |

53.1 Nm

39.1 lb-ft |

| Fuel tank capacity |

20.4 L

5.39 gal. |

|

Electrical

|

| Battery size |

500 CCA |

| Alternator (12-V) |

40 amp |

| Starter size |

1.2 kW

1.6 hp |

|

Fuel system

|

| Fuel consumption |

5.8 L/hr

1.5 U.S. gal./hr |

|

Transmission

|

| Left-hand reverser |

No |

| Final drive |

Spur gear |

| Brakes |

Wet disc |

| Steering |

Power steering |

| Axle capacity |

Front

612 kg

1349 lb

Rear

1100 kg

2425 lb

|

| Creeper |

No |

|

Final drive

|

| Differential lock |

Yes |

|

Hydraulics

|

| Pump rated output |

Steering

13.25 L/min

3.5 gpm

Implement

13.25 L/min

3.5 gpm

26.5 L/min

7.0 gpm |

| Pump type |

Gear |

| Maximum operating pressure |

137 bar

1987 psi |

| Draft control sensing |

Position control |

| Remote control valves available |

Two |

|

Power take-off (PTO)

|

| Standard |

Rear - 540 rpm

Mid - 2100 rpm |

| Control |

Independent |

| Clutch |

Wet disk |

| Brake (for mid and rear PTO) |

Wet disk |

|

Fluid capacities

|

| Crankcase with filter |

2.7 L

2.9 gal. |

|

Operator station

|

| Rollover protective structure |

Type

Foldable

OSHA, SAE, ASAE |

| Platform - flat/straddle |

Three-piece semi flat |

| Gear shift location - console/floor |

Left-hand side |

|

Dimensions

|

| Front axle clearance |

316 mm

12.5 in. |

| Turning radius without brakes |

Outside front tire: 2.51 m

8.2 ft |

| Limited slip differential |

No |

|

Tires

|

| Front |

R3 Turf: 23x8.50-12

R3 Radial: 220/55-R12

R4 Industrial: 23x8.50-12 |

| Rear |

R3 Turf: 12-16.5

R3 Radial: 280/70 R16

R4 Industrial: 12-16.5 |

| Front tread range |

95.3 cm

37.5 in. |

|

Miscellaneous

|

| Toolbox |

Yes |

| Tilt steering wheel |

Yes |

| 12-V Outlet |

Yes |

Accessories and Attachments

Ballast Box Extension - BW15074

Auto-Throttle Kit - BLV10784

Engine Coolant Heater Kit (110 Volt) - BLV10640

Front Attaching Support kit (model year 2017- 2025R, 2026R) - BLV10680

220/55-12 (R3 Turf) Radial Front Wheels & Tires - BLV10745

23x8.5-12 (R3 Turf) Bias Ply Front Wheels & Tires - BLV10741

23x8.5-12 (R4 Industrial) Bias Ply Front Wheels & Tires - BLV10743

Rear Hydraulic Outlet Kit - BLV10775

Single Rear Selective Control Valve (SCV) Kit Without Detent - BLV11025

Power Beyond Kit - BLV11238

Auxiliary Rear Work Light Kit (1 Light) - LVB25547

Forward Lighting Kit (2 Lights) - LVB25546

LED Work Light Kit - BLV10497

Warning Light Brush Guard Kit (Two Guards) - BLV10400

Work Light Brush Guard Kit (OOS Only) - BLV10399

Spark Arrester Screen for Muffler - LVA15392

55-amp alternator - LVB25015

Rear License Plate Kit (Includes Light) - BLV11042

Canopy Kit - Rigid Plastic - LP64809

Front Weight Bracket Extension Kit (1023E, 1025R, 1026R, 2305, 2025R, 2026R, 2320, 2520, 2027R, 2032R) - BLV10623

Rear Wheel Weight, 60 lb (27.2 kg) - BM17965

Attaching Hardware for Rear Wheel Weight, 60 lb - BM17987

12-16.5 (R3 Turf) Bias Ply Rear Wheels & Tires - BLV10740

12x16.5 (R4 Industrial) Bias Ply Rear Wheels & Tires - BLV10742

280/70-16 (R3 Turf) Radial Rear Wheels & Tires - BLV10744

3-Point Hitch Tractor Receiver Hitch - LP25001

iMatch Quick Hitch Upper Adapter Bushing - PM03008

iMatch Quick Hitch Upper Adapter Bushing - PM00353

iMatch Bushing Kit - LP25004

iMatch Quick Hitch Bushings - LVU15507

iMatch/Quik-Coupler Brushing Kit - BW15056

iMatch Quick Hitch Bushings - LVU12858

iMatch Quick-Hitch Category 1 with adjustable top hook - LVB25976

iMatch Bushing Kit - LP19969

Quik-Tatch Weight, 42 lb (19 kg) - UC13263