*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories

Silver logo denotes the ATU 200

Silver logo denotes the ATU 200

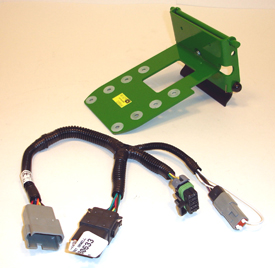

The AutoTrac© Universal (ATU) 200 steering kit is a mobile guidance solution that brings additional productivity to farming operations throughout the growing season.

ATU 200 is approved on over 450 different equipment platforms and is compatible with all levels of StarFire accuracy.

The benefits of the ATU 200 over the original ATU include:

AutoTrac Universal 200 steering kit

AutoTrac Universal 200 steering kit

Quick and easy setup

Quick and easy setup

With the mobile AutoTrac Universal (ATU) 200 steering kit, producers can leverage their investment in AutoTrac across many approved machine platforms throughout the growing season.

This means producers can move their ATU 200 steering system from their planting tractor in the spring, to their sprayer in the summer, then into their combine, and finally to their tillage tractor in the fall.

Best of all, the ATU 200 moves from machine to machine in about an hour depending upon the platform. By moving this system, operators can experience the value of automatic guidance year-round.

Achieve critical accuracy of in-field operations

Achieve critical accuracy of in-field operations

As equipment gets larger and margins tighter, accuracy of in-field operations and input placement is more critical than ever.

When making a pass in a field, traveling from one end of the field to another, the position accuracy of the return pass is critical. Pass-to-pass accuracy means the planter guess rows will be accurate and subsequent passes are less likely to result in crop damage.

Repeatability defines how accurately the receiver calculates its position over a relatively long time window.

AutoTrac reduces overlap

AutoTrac reduces overlap

AutoTrac maintains speed

AutoTrac maintains speed

Farming requires multiple passes. This requires a method of guidance with a high degree of repeatability in order to minimize overlap (extra cost of seed, fertilizer, chemical and machine hours) and skips (loss of production).

Maintaining repeatable accuracy is important in all operations, especially with cropping practices that require multiple passes through the field. AutoTrac creates more consistent row spacing, reducing the potential for crop damage with subsequent passes through the field.

University studies have shown that operators tend to overlap 5 to 13 percent over the course of an entire day, which could mean up to 60 cm (23 in.) of overlap with a 6 m (19 ft) tillage implement. This means that a producer with 300 ha (740 acres) actually works and pays for 330 ha (815 acres).

With reducing overlap by using AutoTrac more ground is covered in the same time and inputs like chemicals, fertilizer, fuel, labor and machine hours are reduced.

Reduced overlap with AutoTrac |

|

Field 1 |

4.72 percent |

Field 2 |

8.03 percent |

Field 3 |

12.74 percent |

Average: |

8.50 percent |

GPS accuracy versus manual accuracy |

|

AutoTrac© assisted steering system greatly increases operator productivity by maintaining consistent accuracy and efficiency. Operators remain more alert while they are in the field and are able to focus on implement settings and varying field conditions. AutoTrac also allows operators to confidently create evenly spaced rows past sunset, as well as in rain, dust, or fog.

AutoTrac increases productivity

AutoTrac increases productivity

AutoTrac also improves operator comfort as the operator has time to concentrate on implement tasks.

Reduce compaction with AutoTrac© guidance system

Reduce compaction with AutoTrac© guidance system

As tractors and field equipment become larger and heavier, there is a growing concern about soil compaction. Heavy equipment and tillage implements can cause damage to the soil structure. Soil structure is important because it determines the ability of a soil to hold and conduct water, nutrients, and air necessary for plant root activity.

By using AutoTrac, operators can optimize the number of passes and reduce compaction. Additionally, the operator can confine traffic between certain rows and avoid compacting the row area.

AutoTrac allows producers to use the same traffic lanes year after year, sacrificing a small portion of the field in favor of having no wheel traffic in the majority of the field. Restricting traffic to specific lanes also provides a firm soil surface for more efficient tractor operation.

Without using AutoTrac during field operations, there is tendency for passes to overlap. Each pass over a field under poor conditions can cause significant damage to the soil.

AutoTrac© guidance steering system allows operators to use tramline management more effectively, minimizing soil compaction. Additionally, AutoTrac allows the machine operator to select from a variety of guidance modes including straight track, AB curves, adaptive curves, circle track, boundary fill, machine access, and swap track. These tracking options allow the operator to select the track best suited for the field and conditions reducing the number of passes needed to cover the field.

Curve track

Curve track

The curve track mode helps operators by automatically steering curved guidance lines on terrain that does not allow for straight track to be used (rolling hills or contours).

When running with curve track, keep in mind these basic principles:

| Simple curve |

|

S-curve |

|

| Boxed |

|

Racetrack |

|

| Spiral |

|

Circle |

|

Two different modes can be used depending on the type of curves that need to be created: adaptive curves or A/B curves.

Adaptive curve track

This track allows the operator to record a manually driven curved guidance line. Operators using a GreenStar© 3 2630 Display have the ability to record and utilize multiple adaptive curves per field. This feature is especially useful as operators maneuver around terraces or irregular, constantly changing fields. Adaptive curve mode also has the ability to connect line segments when documentation is selected as the recording source. Self-propelled forage harvester or combine operators may find this functionality useful if they need to quickly raise their header for any reason.

The curve adapts, if driven around an obstacle

The curve adapts, if driven around an obstacle

The curvature of the line changes down the field

The curvature of the line changes down the field

A/B curve track

This track allows the operator to set a curved line in a field with two end points (A and B) and will generate guidance lines parallel to the initial track in either direction.

Skip pass

Skip pass

The line stays the same across the field, and an operator can use skip track.

Field obstacles

Field obstacles

Even if an operator drives around an obstacle in the field, the next pass follows the original track line.

Subsequent passes are identical to the first pass

Subsequent passes are identical to the first pass

The straight track mode helps operators by automatically driving straight. Operators can create an initial straight line using a variety of different setup options.

Once the track has been defined, all subsequent track lines in the field are created parallel to each other at the defined track spacing distance.

Circle track mode on the display

Circle track mode on the display

The circle track mode helps operators drive concentric circles in a field when a circle is set up and guidance is being used. Operators can create an initial circle using a variety of different methods. Once the initial circle has been defined, all the subsequent circles in the field are created.

Circle track is available in Parallel Tracking mode. Pivot Pro activation must be purchased to use circle track with automatic guidance.

Pivot Pro tracking mode

Pivot Pro tracking mode

The Pivot Pro module allows the operator to automatically guide a machine in defined concentric circles in fields with center-pivot irrigation systems.

Circle track functionality is included with GreenStar Basics, allowing the operator to manually guide the machine around the concentric circle without an upgrade activation. Pair Pivot Pro activation with GreenStar AutoTrac to have the machine drive circles automatically.

Pivot Pro is approved for level fields, as accuracy can be degraded as slope increases. If there is slope in the field, there is the potential the circle track space and the center-pivot tower track will not match up. Keep in mind, AutoTrac draws the circle spacing as if the plane were level.

Active Implement Guidance© uses the follow track mode

Active Implement Guidance© uses the follow track mode

Unique to John Deere Active Implement Guidance, the follow track mode assists the driver when operating headlands or navigating around obstacles, allowing the implement to follow the tractor guidance path. This helps reduce crop damage and soil compaction.

Tramline screen

Tramline screen

Tramline management provides the opportunity to setup and edit certain guidance lines as tramlines. Those lines will be highlighted in a separate color in the guidance screen. Tramline management is available on the GreenStar 3 2630 Display in straight track, AB curve, and circle track modes.

Tramlines can be set and stored for each A-B line in the display. This allows the operator to properly seed and plant fields with accurate tramlines defined. This will make it easier to reduce inputs on all following field operations such as spraying.

NOTE: Tramline management is not currently available on the GreenStar 3 CommandCenter© controls.

Swap track

Swap track provides operators the ability to quickly switch guidance modes as they work through fields varying geographic conditions. Operators can easily move from straight track to any of the other tracking modes as needed. Swap track allows the operator to toggle between up to four different guidance lines within the same field on the GreenStar 3 2630 Display. Operators can also change the track order while AutoTrac is engaged.

Swap track is available on the GreenStar 3 2630 Display.

NOTE: Swap track is not available on the GreenStar 3 CommandCenter.

This document lists all the compatible equipment approved with the software update 19-2 release, and is subject to change with newer software updates. To ensure complete and proper compatibility, the most current version of implement control unit software, Generation 4 Display software, or compatible farm management information software (FMIS) should be used. Non-current software versions will require an update before support can be provided. Unapproved software version configurations will not be supported.

The software update 19-2 release is only compatible with 4600 CommandCenter© v2 processors. Software update 17-2 is the last release that was compatible with 4600 v1 processors.

Server serial numbers are as follows:

John Deere Large Ag Tractors

| John Deere Large Ag Tractors (list of all automatically detected machines) |

Model year | CommandCenter display | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| 9R/9RT/9RX Series | 2018 and newer | X | --- | X | X |

| 9R/9RT/9RX Series | 2015-2017 | * | --- | X | X |

| 9R/9RT Series | 2012-2014 | --- | --- | X | X |

| 9030/9030T Series | 2008 and newer | --- | --- | X | X |

| 9020/9020T Series | 2002-2007 | --- | --- | X | --- |

| 9000 Series | 1997-2001 | --- | --- | X | --- |

| 9000T Series | 2000-2001 | --- | --- | X | --- |

| 8R/8RT Series | 2018 and newer | X | --- | X | X |

| 8R/8RT Series | Mid-2014 - 2017 | * | --- | X | X |

| 8R/8RT Series | 2010-2013 | --- | --- | X | X |

| 8030/8030T Series | 2006 and newer | --- | --- | X | X |

| 8020/8020T Series | 2002-2005 | --- | --- | X | --- |

| 8010/8010T Series | 2000-2002 | --- | --- | X | --- |

| 8000 Series | 1994 | --- | --- | X | --- |

| 8000T Series | 1997-1999 | --- | --- | X | --- |

| 7R Series | 2018 and newer | X | X | X | X |

| 7R Series | 2014-2017 | * | --- | X | X |

| 7R Series | 2011-2013 | --- | --- | X | X |

| 7J Series | 2018 and newer | --- | --- | X | X |

| 7030 Series | 2007 and newer | --- | --- | X | X |

| 7030 Series (Large Frame) | 2007 and newer | --- | --- | X | X |

| 7030 Series (Small Frame) | 2006 and newer | --- | --- | X | X |

| 7010 Series | 1997-2003 | --- | --- | X | --- |

| 7000 Series | 1992-1996 | --- | --- | X | --- |

| 6030 Series (Small Frame) | 2006 and newer | --- | --- | X | X |

| 6000 Series | 1992-1998 | --- | --- | X | --- |

| 6010 Series | 1999-2002 | --- | --- | X | --- |

| 6R Series | 2018 and newer | X | X | X | X |

| 6R Series (Final Tier 4) | 2015-2017 | * | --- | X | X |

| 6R Series (Interim Tier 4) | 2013-2015 | --- | --- | X | X |

| 6M Series | 2013 and newer | --- | --- | X | X |

| 6J Series | 2018 and newer | --- | --- | X | X |

| 5R Series | 2019 and newer | --- | --- | X | X |

*NOTE: For latest Precision Ag functionality, update machines equipped from the factory with v1 processor to v2. The 4640 Universal Display is not compatible with SeedStar© 4HP Planters when installed on 00, 10, and 20 Series Tractors.

John Deere Nutrient Applicators

John Deere Nutrient Applicators |

Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| F4365 High-Capacity Nutrient Applicator | 2017 and newer | X | --- | --- | --- |

John Deere Self-Propelled Sprayers

| John Deere self- propelled sprayers |

Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| 4 Series Sprayers | 2018 and newer | X | --- | --- | --- |

| 4 Series Sprayers | 2013 - 2017 | --- | --- | X | --- |

| 4940 | 2012 - 2014 | --- | --- | X | --- |

| 4630 | 2008 and newer | --- | --- | X | --- |

| 4730 | 2008 and newer | --- | --- | X | --- |

| 4830 | 2008 - 2014 | --- | --- | X | --- |

| 4930 | 2008 - 2013 (SN 4000+) | --- | --- | X | --- |

| R4040i | 2014 and newer | --- | --- | X | --- |

| R4050i | 2017 and newer | --- | --- | X | --- |

| 5430i | 2008 - 2014 | --- | --- | X | --- |

| Hagie© sprayers | 2014 and newer | Compatible with GreenStar© 3 2630 Displays and 4640 Universal Displays* | |||

*NOTE: When using the 4640 Universal Display on a Hagie Sprayer, additional mounting and harnessing may be required.

NOTE: Current John Deere/Hagie field kits only offer GreenStar 3 2630 Display parts.

NOTE: AutoTrac© Vision/AutoTrac RowSense and multi-rank section control are not supported on Hagie at this time.

NOTE: VIN detection is not supported on Hagie Sprayers at this time.

John Deere Self-Propelled Forage Harvesters (SPFH)

John Deere Self-Propelled |

Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| 9000 Series SPFH | 2019 and newer | --- | --- | X | --- |

| 8000 Series SPFH | 2015 and newer | --- | --- | X | --- |

John Deere combines

| John Deere combines | Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| S700 Series | 2018 and newer | X | --- | --- | --- |

| S430 and S440 | 2017 and newer | X | --- | --- | --- |

| S600 Series | 2012 - 2017 | --- | --- | X | X |

| S540 and S550 Series | 2012 and newer | --- | --- | X | X |

| T-Series | 2012 and current | --- | --- | X | X |

| W-Series | 2012 and current | --- | --- | X | X |

| 70 Series | 2008 - 2013 | --- | --- | X | X |

NOTE: Competitive equipment may be compatible with 4640 Universal Display and 4240 Universal Display. For additional compatibility information, contact a John Deere dealer.

John Deere planters

SeedStar© 4HP planters are only compatible with 4600 CommandCenter displays with a version 2 (v2) processor and 4640 Universal Displays. Displays should be running Generation 4 OS software version 10.10.404-390 or newer and the most current version of tractor applications to be compatible with SeedStar 4HP planter applications. Additionally, dual-display mode is available for use with SeedStar 4HP planter applications, along with Generation 4 Extended Monitor. SeedStar 4HP planters are compatible with no more than two GreenStar Rate Controllers.

The SeedStar 2 configuration below is available only on factory-installed model year 2011 and newer planters and may be field-installed on model year 2009 and 2010 planters. Green PM/PA controllers (factory-installed on model year 2009 and 2010 planters) are not supported with a Generation 4 display.

A Service ADVISOR© tool (available at a John Deere dealer) is needed to update SeedStar 2, SeedStar XP, and SeedStar 3 HP software. Documentation is not supported when using a rate controller to control row clutches on a John Deere planter.

| John Deere planters | Control unit name | Software version (or newer) | CommandCenter display | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240* | |||

| SeedStar 2 |

Black PM1 | 22.0 | X | X | X | X |

| Black PA1, (if available PA 2) | 22.0 | X | X | X | X | |

| Green PM1 | 10.11 | --- | --- | --- | --- | |

| Green PA1 (if available PA 2) | 10.11 | --- | --- | --- | --- | |

| SeedStar XP |

Black PM1 | 22.0 | X | X | X | X |

| Black PA1, (if available PA 2) | 22.0 | X | X | X | X | |

| PM2 | 7.0 | X | X | X | X | |

| SeedStar 3 HP |

Planter Main A (PCMA) | 5.0 | X | X | X | X |

| Planter Main B (PCMB or MMC) | 8.0 | X | X | X | X | |

| Row-unit Controller (RUC) | 2.0 | X | X | X | X | |

| EPG | 3.0 | X | X | X | X | |

| SeedStar 4HP |

Planter Apps | 10.4.2-29 | X | --- | X | --- |

| Planter Main A (PMCA) | 5.0 | X | --- | X | --- | |

| Planter Main B (PMCB or MMC) | 6.0 | X | --- | X | --- | |

| Row-unit Controller (RUC) | 3.0 | X | --- | X | --- | |

| Electrical Power Generation (EPG) | 5.0 | X | --- | X | --- | |

| Electrical Power Module, 2 (PC2) | 3.0 | X | --- | X | --- | |

*NOTE: For implements requiring ground speed input (radar), utilizing a 4240 Universal Display may require an additional 4240 Radar speed kit.

John Deere Air Seeders

The C850 Air Cart requires a 4600/4200 CommandCenter Display or a 4640/4240 Universal Display. GreenStar 3 2630 monitors are not supported. Additionally, C850 Air Carts and AutoTrac Implement Guidance (passive) are compatible with software update 18-2 and newer.

| John Deere Air Seeder | Model year/control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240* | |||

| C850 Air Cart |

Cart Master Controller (CMC) | 12 | X | X | X | X |

| Mini Tank Controller (TXC) | 6 | X | X | X | X | |

| Front, Middle, Rear Tank Controller (TCU) | 6 | X | X | X | X | |

| 1870 Seeding Tool - TruSet© system | 2017 and newer (IDC) | 5.0 | X | X | X | X |

| 1870 Seeding Tool - RelativeFlow© blockage sensors | 2017 and newer (BMU) | 4.0 | X | X | X | X |

| 1910 Air Cart - ground drive | 2009 and newer | 3.0 | X | X | X | X |

| 1910 Air Cart - hydraulic drive |

2013 and newer | 8.00 | X | X | X | X |

| Seeding tools with air-run blockage - primary blockage |

2009 and newer (BMU) | 12.0 | X | X | X | X |

| Seeding tools with air-run blockage - air-run blockage | 2009 and newer (BMU) | 12.0 | X | X | X | X |

| Member Module | 5.0 | X | X | X | X | |

| 1990 Central Commodity System (CCS©) |

2009 and newer (BMU) | 12.0 | X | X | X | X |

| N500C Series | Seeding apps | 10.1.495-31 | X | --- | X | --- |

| SMCA or SMC | 2.0 | X | --- | X | --- | |

| SMCB or BMU | 2.0 | X | --- | X | --- | |

| EPG | 2.0 | X | --- | X | --- | |

*NOTE: For implements requiring ground speed input (radar), utilizing a 4240 Universal Display may require an additional 4240 Radar speed kit.

John Deere Tillage

| John Deere Tillage | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| AccuDepth© cultivator | Implement Depth Control (IDC) | 11 | X | X | X | X |

| 2730 with TruSet |

Tillage Controller 1 (TC1) | 2.66K | X | X | X | X |

| 2230 with TruSet | Tillage Controller 1 (TC1) | 2.75K | X | X | X | X |

| 2330 with TruSet | Tillage Controller 1 (TC1) | 3.35K | X | X | X | X |

| 2620/2630 with TruSet | Tillage Controller 1 (TC1) | 2.95K |

X | X | X | X |

| 2720 with TruSet | Tillage Controller 1 (TC1) | 2.24K | X | X | X | X |

| 2660VT with TruSet | Tillage Controller 1 (TC1) | 2.03K | X | X | X | X |

| 2430 with TruSet | Tillage Controller 1 (TC1) | 2.14K | X | X | X | X |

| 2510H with TruSet | Tillage Controller 1 (TC1) | 2.85K | X | X | X | X |

*NOTE: For implements requiring ground speed input (radar), utilizing a 4240 Universal Display may require an additional 4240 Radar speed kit.

John Deere Round Balers

| John Deere Round Balers | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| 0 Series | Baler Automation | 10.07 | X | X | X | X |

| 9 Series Premium |

Baler Automation | 7.16 | X | X | X | X |

| V451R/V461R | Baler Automation | 11.5 | X | X | X | X |

John Deere Large Square Balers

| John Deere Large Square Balers Including Harvest Tec applicator and PhiBer accumulator |

Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| 0 Series | Gen 4 VT | 3.04 | X | X | X | X |

| 1 Series |

Gen 4 VT | 5.07 | X | X | X | X |

| John Deere control units | Control unit name | Software version (or newer) | CommandCenter display | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| *StarFire 6000 Receiver | --- | 4.10J | X | X | X | X |

| StarFire 3000 Receiver | --- | 2.32H | X | X | X | X |

| *Modular Telematics Gateways (MTG) - 3G | --- | 21.03 | X | X | X | X |

| *MTG - 4G | --- | 25.01.746 | X | X | X | X |

| GreenStar Rate Controller | --- | 3.70K | X | X | X | X |

| GreenStar Rate Controller Dry | --- | 2.11A | X | X | X | X |

| *John Deere Rate Controller 2000 | --- | 1.13A | X | X | X | X |

| *AutoTrac Universal 200 | --- | 2.30A | --- | --- | X | X |

| *AutoTrac Universal 300 | --- | 3.22O | --- | --- | X | X |

| AutoTrac Controller 250 | --- | 11933B | --- | --- | X | X |

| *AutoTrac Controller - Deere | --- | 1.11B | --- | --- | X | X |

| AutoTrac Controller - Raven | --- | 3.2.29 | --- | --- | X | X |

| AutoTrac Controller - Reichhardt® | --- | SW 1.3 | --- | --- | X | X |

| AutoTrac RowSense© | RG3 | AKK15783F | X | --- | X | --- |

| AutoTrac Vision | VGC | 4.01L | X | --- | X | --- |

| AutoTrac Turn Automation | --- | 19-2 | X | --- | X | --- |

| AutoTrac Implement Guidance | --- | 19-2 | X | --- | X | --- |

| Active Implement Guidance (VT) | Application 1100 | 2.71 T | X | X* | X | X* |

| iGrade© | Application 1100 | 2.71 T | X | X | X | X |

| Distance Trip | Application 1100 | 2.71 T | X* | X | X | X |

| Gen 4 Extended Monitor | X | --- | X | --- | ||

| Wireless Data Server | Wireless Data Server | 1.541.2 (Planting) |

X | --- | X | --- |

| Mobile Data Transfer | MyTransfer© app | 3.8.6 (iOS®) |

X | X | X | X |

| Connect Mobile app | Connect Mobile app | 8.0.1 or newer | X | --- | X | --- |

| Connect Mobile server | Connect Mobile server | 2.3.87-1 | X | --- | --- | --- |

| Mobile Weather | Application 1120 | 1.51 V | X | X* | X | X* |

| Manure Constituent Sensing | Manure Controller | 19.06 | X | --- | X | --- |

*NOTE: See additional information below.

StarFire Receivers

StarFire Receivers can be updated in the following ways:

Additionally, StarFire iTC Receivers are no longer supported with software update 2017-1 and newer software. StarFire 6000 Receivers require software version 3.80F or higher when used with AutoTrac Implement Guidance.

John Deere Operations Center

To use RDA on a Generation 4 CommandCenter Display with a GreenStar 3 2630 Display connected in the same machine, GreenStar 3 2630 software version 3.22.1095 (SU2014-1) or higher is required (for 4600 CommandCenter Display and 4640 Universal Display only).

GreenStar Rate Controller and GreenStar Rate Controller Dry

GreenStar Rate Controller Dry is supported with display software update 2017-2 and newer. The 4600 and 4200 CommandCenter Displays and 4640 and 4240 Universal Displays support documentation and section control of up to five GreenStar Rate Controller units.

To update the GreenStar Rate Controller and GreenStar Rate Controller Dry, utilize a Generation 4 Display USB port. John Deere dealers can also utilize Service ADVISOR©. GDC 2.11A was the last software version available through Software Manager. GDC 2.20A has been available since spring 2015 and contains diagnostic language updates. This software can only be obtained through Service ADVISOR.

John Deere Rate Controller 2000

The Generation 4 Displays and John Deere Rate Controller 2000 can support documentation and control up to five operations. ISO controllers such as SeedStar or TruSet can be used alongside a John Deere Rate Controller 2000 that is documenting additional operations. The John Deere Rate Controller 2000 will not control the planter clutches or half-, third-, or quarter-width disconnects on a John Deere planter.

AutoTrac© Vision

AutoTrac Vision Guidance Camera 19-1 software 4.01L is only compatible with RowGuidance 3 Controller software AKK15783F and GreenStar 3 2630 17-1 software 3.34.1345 or newer and Generation 4 18-1 software 10.10.404-345 or newer.

AutoTrac Universal 200, AutoTrac Universal 300, and AutoTrac Controller

AutoTrac Universal 200, AutoTrac Universal 300, and AutoTrac Controllers are for use with the 4640 Universal Display and 4240 Universal Display. Please see a John Deere dealer for exact model compatibility.

ISOBUS implements

Generation 4 Displays are compatible with one Agricultural Industry Electronics Foundation (AEF) certified ISOBUS implement; AEF-certified ISOBUS implements with Task Controller Section Control (TC-SC) functionality and AEF certification for TC-SC include sprayers, fertilizer spreaders, planters, seeders, manure applicators, etc. For third-party FMIS compatibility, reference the John Deere Operations Center.

A software update performed by an authorized ISOBUS implement dealer may be required to obtain compatible software. ISOBUS implements must be certified through the Agricultural Industry Electronics Foundation (AEF) to be recognized by the Generation 4 CommandCenter display. Visit www.aef-online.org for more information; visit www.aef-isobus-database.org for an active list of compatible implements.

ISOBUS implements with VT4 are now supported by Generation 4 Displays. Generation 4 Displays still support older VT versions (example: VT2 and VT3). If an implement is not loading after updating to Generation 4 software update 2017-2 (or newer on 4600 CommandCenter v2 processors), it is recommended that the implement manufacturer be contacted to get a software version that is either VT3 or VT4.

Extended monitor

When using an extended monitor with equipment visualized in ISOBUS VT Viewer and applying VT run page modules to two run pages shown at the same time, the extended monitor’s VT modules will not update. To mitigate this, only view VT modules on one run page at a time.

Implements without controllers

Implements without controllers can be documented as a stand-alone operation or with a rate controller from John Deere. Additionally, multiple implements without controllers cannot be documented together.

AutoTrac Implement Guidance (passive)

AutoTrac Implement Guidance is compatible with SeedStar 3HP, SeedStar 2 and SeedStar XP.

AutoTrac Implement Guidance is compatible with C850 Tow-Behind Air Carts with software update 18-2.

AutoTrac Implement Guidance is not compatible with the SeedStar 4 HP planters.

AutoTrac Implement Guidance is not compatible on 4240 Universal Displays for shared signal applications.

AutoTrac Turn Automation

To use the AutoTrac Turn Automation application, specific compatibility is required. AutoTrac Turn Automation is compatible with the following machines:

NOTE: Integrated tractor IMS must be turned off on 30-Series Tractors to use AutoTrac Turn Automation on the Generation 4. Integrated Tractor iTEC must be turned off on the following tractors to use AutoTrac Turn Automation on the Generation 4:

NOTE: If instead an operator chooses to use the machine’s integrated IMS/iTEC functionality, then AutoTrac Turn Automation and iTEC must be turned off in the Generation 4 Universal Display.

AutoTrac Turn Automation is compatible with SeedStar 3HP, SeedStar 2 and SeedStar XP.

AutoTrac Turn Automation is NOT compatible with SeedStar 4HP planters.

Distance Trip documentation

A UCC2 Application Controller 1100 with 19-2 software running on a 4600 CommandCenter v2 server enables documentation of field operations. If a UCC2 replaces a UCC1 Application Controller 1100 on a CommandCenter v1 server, documentation is not available. Refer to Tech Manual Bulletin 137919 to determine server type.

Camera compatibility

Voyager® cameras are supported on Generation 4 Displays. All other camera types are not supported.

Non-John Deere Precision Ag

4600 CommandCenter v2 and the 4640 Universal Display are compatible with the following RS-232 configurations with software update 18-2 and newer:

Machine Communication Radio (MCR)

Generation 4 displays are not compatible with MCR.

APEX© software

NOTE: Gen 4 data is only compatible with the John Deere Operations Center. All Gen 4 activations are machine specific and cannot be transferred to a different machine. If not using WDT, an 8- to 32-GB USB is r

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit Machines must be GreenStar™ ready to be compatible with the AutoTrac machine kits. AutoTrac machine kits include the appropriate machine steering controller when necessary and AutoTrac-ready accessories. Display, receiver, and software to complete system sold separately.

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit  AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac SPFH base kit for non-ProDrive

AutoTrac SPFH base kit for non-ProDrive AutoTrac SPFH base kit for ProDrive transmissions

AutoTrac SPFH base kit for ProDrive transmissions AutoTrac SPFH controller for 7000 and 7050 Series

AutoTrac SPFH controller for 7000 and 7050 SeriesMachines must be GreenStar™ ready to be compatible with the AutoTrac machine kits. AutoTrac machine kits include the appropriate machine steering controller when necessary and AutoTrac-ready accessories. Display, receiver, and software to complete system sold separately.

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

Combine vehicle kit for 70 Series

Combine vehicle kit for 70 Series AutoTrac sprayer vehicle kit

AutoTrac sprayer vehicle kit  AutoTrac sprayer vehicle kit for 4710 models

AutoTrac sprayer vehicle kit for 4710 models  AutoTrac sprayer vehicle kit for 4710 models

AutoTrac sprayer vehicle kit for 4710 models AutoTrac sprayer vehicle kit for 4720 models

AutoTrac sprayer vehicle kit for 4720 models AutoTrac sprayer vehicle kit

AutoTrac sprayer vehicle kit AutoTrac sprayer vehicle kit for 4920 models

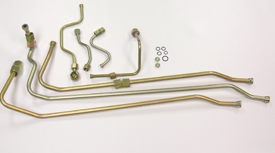

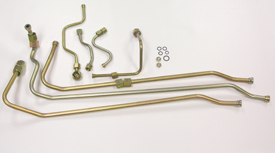

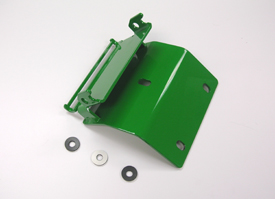

AutoTrac sprayer vehicle kit for 4920 modelsAutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

StarFire™ Receiver and signal options:

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

StarFire™ Receiver and signal options:

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

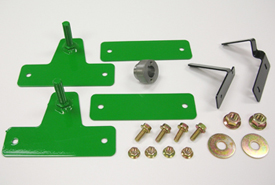

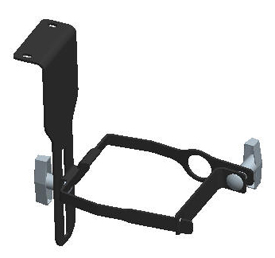

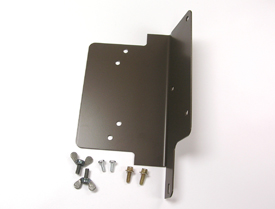

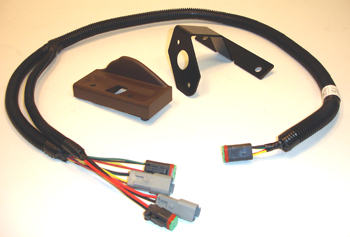

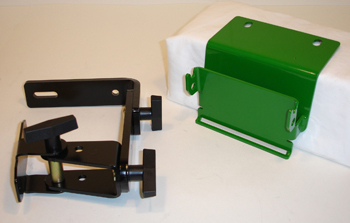

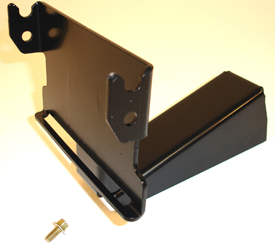

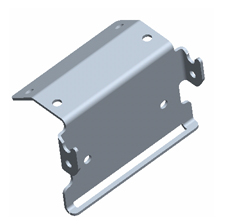

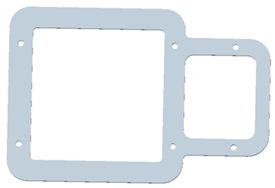

AutoTrac tractor vehicle kit items

AutoTrac tractor vehicle kit items More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items AutoTrac tractor vehicle kit items

AutoTrac tractor vehicle kit items More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit itemsWhen paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

AutoTrac tractor vehicle kit items

AutoTrac tractor vehicle kit items More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit itemsAutoTrac field-installed kits are now available for 6210R, 6190R, and 6170R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors.

All required hydraulic components and harnesses for field installation are contained in these kits.

GreenStar™ display options:

StarFire™ Receiver and signal options:

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

StarFire™ Receiver and signal options:

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

StarFire™ Receiver and signal options:

The AutoTrac system reduces overlap, saving time, fuel, and labor costs. Whether breaking stubble with tillage equipment, planting or seeding, spraying or fertilizing, it reduces implement overlap by up to 90 percent. It also provides faster headland turns because the AutoTrac system takes the guesswork out of the return path.

RowSense retrofit kit for corn head

RowSense retrofit kit for corn head RowSense retrofit kit for combine

RowSense retrofit kit for combine![RowSense mechanical feelers (70-cm [27.6-in.] row spacing)](https://salesmanual.deere.com/sales/salesmanual/images/NA/ams/bundles/pf90698-1.jpg) RowSense mechanical feelers (70-cm [27.6-in.] row spacing)

RowSense mechanical feelers (70-cm [27.6-in.] row spacing)![RowSense mechanical feelers (56-cm [22-in.] row spacing)](https://salesmanual.deere.com/sales/salesmanual/images/NA/ams/bundles/pf90700.jpg) RowSense mechanical feelers (56-cm [22-in.] row spacing)

RowSense mechanical feelers (56-cm [22-in.] row spacing)![RowSense mechanical feelers (51-cm [20-in.] row spacing)](https://salesmanual.deere.com/sales/salesmanual/images/NA/ams/bundles/pf90699.jpg) RowSense mechanical feelers (51-cm [20-in.] row spacing)

RowSense mechanical feelers (51-cm [20-in.] row spacing) Universal steering supplemental kit - "I"

Universal steering supplemental kit - "I"| PF12364 | Hub, taper spline |

| PF12415 | Bracket, anti-rotation |

| RE52952 | Clamp |

| Ag-Chem™ | Sprayer | TerraGator® | 1603/1803/1903 |

| Ag-Chem | Sprayer | TerraGator | 1664/1804/1844 |

| CAT® | Tracks | E | 65/75/85/95 |

| CAT | Tracks | D | 65/75/85 |

| Caterpillar | Tracks | C | 65/70/75/85 |

| Case® IH | 4WD | Steiger® | 9310/9330/9350/9370/9380/9390 |

| Case IH | 4WD | Steiger | 91,92,9x10/9x30/9x50/9x70/9x80/9x90 |

Ag-Chem and TerraGator are trademarks of AGCO Corporation. CAT is a U.S.-registered trademark of Caterpiller Incorporated. Case and Steiger are U.S.-registered trademarks of CNH Global N.V. and its subsidiaries.

AutoTrac Universal steering supplemental kit -"Q"

AutoTrac Universal steering supplemental kit -"Q" Universal steering supplemental kit - "J"

Universal steering supplemental kit - "J"| PF12341 | Hub, taper spline |

| PF80987 | Harness, combo power adapter |

| PF12467 | Bracket, cab roof (StarFire™) |

| PF12440 | Bracket, anti-rotation |

| PF12441 | Spacer, anti-rotation |

Universal steering supplemental kit - "K"

Universal steering supplemental kit - "K"| PF12339 | Hub, taper spline |

| PF12415 | Bracket, anti-rotation |

| RE52952 | Clamp, band |

| AGCO®/Willmar® | Sprayer | Eagle | 8400/8450/8500 |

| Case® IH | Sprayer | FLX | 4275/4300/4330/4375 |

| Case IH | Sprayer | FLX | 3275/3300/3330 |

| Spra-Coupe® | Sprayer | 4000 Series | 4450/4650 |

| Spra-Coupe | Sprayer | 4000 Series | 4440/4640 |

AGCO, Willmar, and Spra-Coupe are U.S.-registered trademarks of AGCO Corporation. Case is a U.S.-registered trademark CNH Global N.V. and its subsidiaries.

AutoTrac Universal steering supplemental kit -"L"

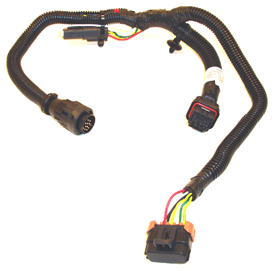

AutoTrac Universal steering supplemental kit -"L"| PF90510 | Bundle, ATU supplemental kit "C" |

| PF80906 | Harness, two-pin/four-pin (mini terminator) |

| PF80921 | Harness, two-pin/four-pin (large terminator) |

| PF80975 | Harness, combine, StarFire™ extension |

| PF80976 | Harness, combine, GSD Y |

| PF80722 | Harness, StarFire to bulkhead |

| AH171496 | Harness, StarFire adapter (metri-pack to Deutsch) |

| John Deere | Combine | 9x60 | 9560/8560 STS™/9660/9660 CTS™/9660 STS/9760 STS/9860 STS/9860 Premium Series |

| John Deere | Combine | 9x50 | 9450/9550/9550 SH/9650/9650 CTS/9650 STS/9750 STS |

| John Deere | Combine | 9x00/9x10 | 9400/9500/9500 SH/9600/CTS/9410/9510/9540 SH/9610/ CTS II |

Universal steering supplemental kit - "M"

Universal steering supplemental kit - "M"| Caterpillar® | Lexion Combine | 450/465/470/475/485/460R/470R/480R (manufactured in 2002 or later) 560/560R/570R/580R/585R/590R |

Caterpillar is a U.S.-registered trademark of Caterpillar Incorporated.

Universal steering supplemental kit - "N"

Universal steering supplemental kit - "N"| Caterpillar® | Lexion Combine | 450/465/470/475/485/460R/470R/480R (manufactured prior to 2002) |

Caterpillar is a U.S.-registered trademark of Caterpillar Incorporated.

Universal steering supplemental kit - "O"

Universal steering supplemental kit - "O"| John Deere | Combine | 9660 WTS |

Universal steering supplemental kit - "P"

Universal steering supplemental kit - "P"| John Deere | Cotton stripper | 7460 |

Universal steering supplemental kit - "R"

Universal steering supplemental kit - "R" AutoTrac Universal steering supplemental kit-"S"

AutoTrac Universal steering supplemental kit-"S"| John Deere | Row-crop tractor | 6x00 |

| John Deere | Row-crop tractor | 6x10 |

| John Deere | Row-crop tractor | 6x20 |

| John Deere | Row-crop tractor | 6x30 Standard Series |

| John Deere | Row-crop tractor | 7x00 Small Frame |

| John Deere | Row-crop tractor | 7x10 Small Frame |

| John Deere | Row-crop tractor | 7x20 Small Frame |

| John Deere | Row-crop tractor | 7x30 Small Frame Standard Series |

| John Deere | Row-crop tractor | 7xx0 HI Crop |

AutoTrac Universal steering supplemental kit -"T"

AutoTrac Universal steering supplemental kit -"T"| John Deere | Sprayer | 4700 |

| John Deere | Sprayer | 4x10 |

| John Deere | Sprayer | 4x20 |

| John Deere | Row-crop tractor | 8x00 |

| John Deere | Row-crop tractor | 8x10 |

| John Deere | Row-crop tractor | 8x20 |

| John Deere | Row-crop tractor | 8x30 |

| John Deere | Row-crop tractor | 7x20 large frame |

| John Deere | Row-crop tractor | 7x30 large frame |

| John Deere | 4WD tractor | 9x00 |

| John Deere | 4WD tractor | 9x20 |

| John Deere | 4WD Tractor | 9x30 |

Universal steering supplemental kit - "U"

Universal steering supplemental kit - "U" Universal steering supplemental kit - "V"

Universal steering supplemental kit - "V" Universal steering supplemental kit - X

Universal steering supplemental kit - XAutoTrac™ is an assisted hands-free steering system that automatically steers the machine through the fields. For some of the competitive sprayers, an AutoTrac Universal Hub will be required along with other attachments. For complete compatibility information, see the ATU look up tool.

AutoTrac Universal horn kit

AutoTrac Universal horn kit AutoTrac™ is an assisted hands-free steering system that automatically steers the machine through the fields. For some of the competitive sprayers, an AutoTrac Universal Hub will be required along with other attachments. For complete compatibility information, see the ATU look up tool.

AutoTrac™ is an assisted hands-free steering system that automatically steers the machine through the fields. For some of the competitive sprayers, an AutoTrac Universal Hub will be required along with other attachments. For complete compatibility information, see the ATU look up tool.

Original Greenstar display slotted bracket

Original Greenstar display slotted bracket AutoTrac Universal steering supplemental kit -"A"

AutoTrac Universal steering supplemental kit -"A"| PF90454 | Bracket, anti-rotation |

| PF80864 | Assembly, GPS bracket |

| PF12140 | Hub, spline |

| Case® IH | Row-crop | MX Maxxum® | 100/110/120/135/150/170 |

| New Holland® | Row-crop | TG | 210/230/255/285 |

| Case IH | Tracks | Quad | 375/425/450/500 |

| Case IH | 4WD | STX® | 275/325/375/425/450/500 |

| Case IH | Row-crop | MX Maxxum | 210/230/255/285 |

| Case IH | Row-crop | MX Maxxum | 180/200/220/240/270 |

| New Holland | 4WD | TJ | 275/325/75/425/450/500 |

| McCormick™ | Row-crop | ZTX | 230/260/280 |

Case, Maxxum, New Holland, and STX are U.S.-registered trademarks of CNH Global N.V. and its subsidiaries. McCormick is a trademark of McCormick International USA Incorporated.

AutoTrac Universal steering supplemental kit, "G"

AutoTrac Universal steering supplemental kit, "G"

| AN191704 | Clamp assembly |

| PF12372 | Bracket, anti-rotation |

| McCormick™ | Row crop | ZTX | 230/260/280 |

| Case® IH | Sprayer | SPX™ | 4410 |

| Case IH | Sprayer | FLX™ | 4010/4510 |

| Case IH | Sprayer | FLX | 3010/3510 |

| AGCO®/Willmar® | Sprayer | Eagle | 8650 |

| McCormick | Row crop | MTX | 120/135/150/165/185/200 |

| Case IH | Row crop | Maxxum® | 5220/5230/5240/5250 |

| Case IH | Sprayer | SPX | 3200/4260 |

| Case IH | Tracks | Quad | 380/430/480/530 |

McCormick is a trademark of McCormick International USA Incorporated. Case, SPX, FLX, and Maxxum are trademarks of CNH Global N.V. and its subsidiaries. AGCO and Willmar are U.S.-registered trademarks of AGCO Corporation.

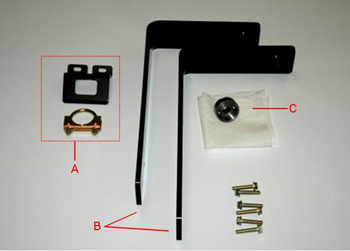

Universal steering supplemental kit - "F"

Universal steering supplemental kit - "F"

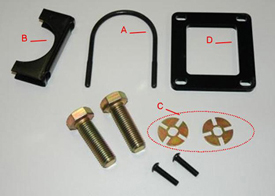

| A | PF90510 | Bundle, ATU bracket kit "C" |

| B | AH211594 | Support, sssembly, GPS receiver |

| Not pictured | PF80722 | Harness, StarFire™ to bulkhead |

| C | PF80167 | Connector plug, StarFire |

| D | PF80873 | Harness, two-pin to convenience outlet |

| E | RE67015 | Harness, convenience outlet to power strip |

| John Deere | Self-propelled forage harvester | 7200/7300/7400/7500/7700/7800 |

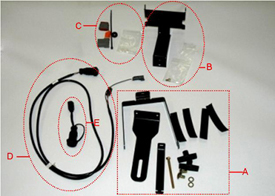

Universal steering supplemental kit - "E"

Universal steering supplemental kit - "E"

| AN278232 | Harness, assembly, 9986/9996 Cotton (StarFire™ receiver) |

| PF80906 | Harness, two-pin/four-pin (mini terminator) |

| PF80722 | Harness, StarFire to bulkhead |

| PF80873 | Harness, two-pin to convenience outlet |

| RE67015 | Harness, convenience outlet to power strip |

| PF90510 | Bundle, AutoTrac Universal (ATU) supplemental kit - "C" |

| John Deere | Cotton Picker | 9986/9996 |

Universal steering supplemental kit - "D"

Universal steering supplemental kit - "D"| Ag-Chem™ | Sprayer | RoGator® | 1254/1264/1274/1274C |

| Ag-Chem | Sprayer | TerraGator® | 6103/8103/9103/9203 |

| Ag-Chem | Sprayer | TerraGator | 8104/8144 |

| New Holland®/Versatile | 4WD | 9184/9384/9484/9684/9886 | |

| GVM® | Sprayer | Prowler | 1149t |

| New Holland | Row crop | 8x70A | 8670A/8770A/8870A/8970A |

| New Holland | Row crop | 8x70 | 8670/8770/8870/8970 |

| Buhler™ | Row crop | Genesis | 2145/2160/2180/2210 |

| New Holland/Versatile | 4WD | 9282/9482/9682/9882 | |

| New Holland/Versatile | 4WD | 9280/9480/9680/9880 | |

| Buhler | 4WD | Versatile | 2290/2335/2360/2375/2425 |

| Challenger® | Tracks | MT | 835/845/855/865/875 |

| Challenger | Tracks | MT | 735/745/755/765 |

| CLAAS® | Tracks | CH | 35/45/55 |

| Case® IH | Combine | AFX | 8010 |

| New Holland | Combine | CR | 940/960/970/980 |

| New Holland | Combine | CX | 840/860/880 |

| New Holland | Windrower | HW | 300/320/340 |

| Hesston® | Windrower | 9260/9240/9230 | |

| Hesston | Windrower | 8550s/8450/8250s | |

| Challenger | Windrower | SP80/SP110/SP165 | |

| New Idea® | Windrower | 5830/5840/5850 | |

| Massey Ferguson® | Windrower | 9220/9420/220 |

Ag-Chem, RoGator, TerraGator, Challenger, Hesston, New Idea, and Massey Ferguson are trademarks of AGCO Corporation. New Holland and Case are trademarks of CNH Global N.V. and its subsidiaries. Buhler is a trademark of Buhler Industries Incorporated. CLAAS is a U.S.-registered trademark of CLAAS KGaA mbH Limited.

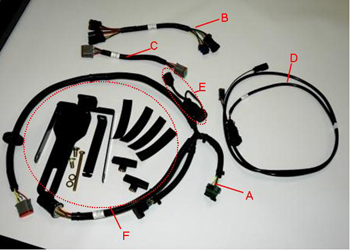

AutoTrac Universal steering supplemental kit, "H"

AutoTrac Universal steering supplemental kit, "H"

| A | PF12243 | U-Bolt |

| B | PF12244 | Saddle |

| C | PF12427 | Telescope washers |

| D | PF12442 | Bracket extension |

| Case® IH | Sprayer | SPX™ | 3150/3185/3310 |

| Case IH | Row Crop | 71x0 Magnum® | 7110/ 7120/7130/7140/7150 |

| Case IH | Row Crop | 72x0 Magnum | 7210/7220/7230/7240/7250 |

| Case IH | Row Crop | 89x0 Magnum | 8910/8920/8930/8940/8950 |

Case, SPX, and Magnum are trademarks of CNH Global N.V. and its subsidiaries.

Harness for Field Doc Connect

Harness for Field Doc Connect GS2 to Orginal GS vehicle connector harness

GS2 to Orginal GS vehicle connector harness GreenStar 2 third-party controller kit

GreenStar 2 third-party controller kit  GreenStar desktop bundle

GreenStar desktop bundle GreenStar ISO implement

GreenStar ISO implement Right-hand console

Right-hand console Stand-alone harness

Stand-alone harness Harness

Harness 35-ft extension harness

35-ft extension harness GreenStar 2 vehicle connector

GreenStar 2 vehicle connector GreenStar 2 vehicle connector

GreenStar 2 vehicle connector Harness

Harness Receiver to cab-roof bulkhead connector

Receiver to cab-roof bulkhead connector StarFire Receiver Deluxe shroud

StarFire Receiver Deluxe shroud Position receiver bracket

Position receiver bracket Position receiver bracket and connector kit

Position receiver bracket and connector kit Mounting kit for GS2 display control unit

Mounting kit for GS2 display control unit Mounting kit for GreenStar 2 display

Mounting kit for GreenStar 2 display  GreenStar tractor bracket kit

GreenStar tractor bracket kit  GreenStar tractor bracket kit

GreenStar tractor bracket kit  GreenStar combine bracket kit

GreenStar combine bracket kit  Position receiver bracket

Position receiver bracket  Combine StarFire position receiver bracket

Combine StarFire position receiver bracket GreenStar dual display bracket

GreenStar dual display bracket  Shroud mount

Shroud mount Surface Water Pro receiver mounting kit

Surface Water Pro receiver mounting kit  High-current power-extension harness

High-current power-extension harness High-current power-adapter harness

High-current power-adapter harness High-current power-adapter harness

High-current power-adapter harness Center extension harness

Center extension harness Center extension harness

Center extension harness Auxiliary-power extension harness

Auxiliary-power extension harnessMachine specific kits provide dealers with all of the hardware and harnessing to equip your 2410C or 2510H with dry applicator with AccuFlow Vortex Cooler minus:

Switch and power extension harness

Switch and power extension harness Rear extension harness

Rear extension harness Surface water implement mast

Surface water implement mast The GreenStar™ Lightbar is a simple, economical Parallel Tracking™ display.

The 27 tracking indicator light-emitting diodes (LED) tell the operator how the machine is tracking in relation to the desired guidance line.

The operator steers the vehicle back to the guidance line.

GreenStar Lightbar can be run as a stand-alone unit or as a companion to either an Original GreenStar Display or GreenStar 2 (GS2) 2600, GreenStar 2 1800, or GreenStar 3 2630 Display.

NOTE: The GreenStar Lightbar cannot be power washed.

Cotton yield sensor kit for 9986 or 9996 models

Cotton yield sensor kit for 9986 or 9996 models First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

Combine moisture sensor retrofit kit on 50 Series

Combine moisture sensor retrofit kit on 50 Series Moisture sensor conversion kit

Moisture sensor conversion kit First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

RTK universal StarFire mounting bracket

RTK universal StarFire mounting bracket  RTK tripod with labels

RTK tripod with labelsPF80762 - Storage case for original GreenStar™ common components

Radio extension harness

Radio extension harness  RTK dual radio harness

RTK dual radio harness RTK conversion bundle

RTK conversion bundle  RTK base station extension harness

RTK base station extension harness  Magnetic rover antenna

Magnetic rover antenna RTK radio cover

RTK radio cover In-line amplifier

In-line amplifier High-gain base antenna

High-gain base antenna