| Engine description | John Deere PowerTech™ PVS |

| Engine displacement | 6.8 L / 415 cu in. |

| Rated engine power | 97/68EC: 129 kW / 175 hp |

| Transmission type | Standard: 20 Speed AutoQuad PLUS™ ECO (40K) / Optional: 16 speed PowerQuad PLUS™ / 20 speed AutoQuad PLUS™ (50K) / DirectDrive ECO™ (40K) / Infinitely variable transmission (IVT) 0.050-42 km/h / 0.030-26 mph / Infinitely variable transmission (IVT) 0.050-50 km/h / 0.030-31 mph |

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories

| Engine description | John Deere PowerTech™ PVS |

| Engine displacement | 6.8 L / 415 cu in. |

| Rated engine power | 97/68EC: 129 kW / 175 hp |

| Transmission type | Standard: 20 Speed AutoQuad PLUS™ ECO (40K) / Optional: 16 speed PowerQuad PLUS™ / 20 speed AutoQuad PLUS™ (50K) / DirectDrive ECO™ (40K) / Infinitely variable transmission (IVT) 0.050-42 km/h / 0.030-26 mph / Infinitely variable transmission (IVT) 0.050-50 km/h / 0.030-31 mph |

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories

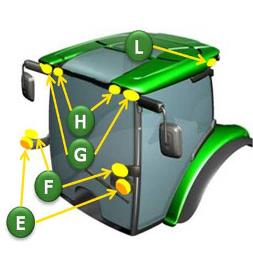

Lights on the 6R Series Tractors have been positioned and designed to provide maximum visibility to the front, sides, and rear of the tractor to increase productivity in any operating condition. The cab lighting pattern provides 330 degrees of coverage while the hood lighting provides the remaining 30 degrees for completely programmable, 360-degree, stadium-style lighting.

Base lighting

Code |

Hood |

Belt |

Front roof |

Side |

Rear roof |

Fender |

|||||||||||

A |

B |

C |

F |

E |

G |

H |

K |

I |

L |

N |

O |

M |

P |

Q |

R |

||

| * Base package - with non-panorama roof | HB3 | HB3 | HB3 | HB3 | HB3 | HB3 | HB3 | HB3 | HB3 | ||||||||

| Light package - Standard | 873F | HB3 | HB3 | HB3 | HB3 | HB3 | LED | X | LED | HB3 | HB3 | HB3 | HB3 | HB3 | HB3 | ||

| Light package - Premium | 873E | HB3 | HB3 | HB3 | HB3 | HB3 | LED | X | LED | HB3 | LED | HB3 | HB3 | HB3 | HB3 | ||

| Light package ™ Base panorama roof code (878W) | HB3 | HB3 | HB3 | HB3 | HB3 | HB3 | HB3 | HB3 | |||||||||

| Light package - Standard - panorama roof | 873A | HB3 | HB3 | HB3 | HB3 | HB3 | LED | X | HB3 | HB3 | HB3 | ||||||

| Lighting package ™ Panorama light package | 873C | HB3 | HB3 | HB3 | HB3 | HB3 | LED | X | HB3 | LED | HB3 | HB3 | |||||

Lighting identification from front view of tractor

Lighting identification from front view of tractor

Lighting availability on panorama roof

Lighting availability on panorama roof

Lighting identification from rear view of tractor

Lighting identification from rear view of tractor

Selecting the lighting mode

Overview

Operators can quickly select a lighting mode on the steering console by operating a rotary switch. The four settings available are:

Lighting control switch on dashboard

Lighting control switch on dashboard

Benefits

Programmable lighting

Overview

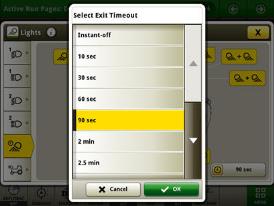

The CommandCenter allows operators to customize two different light programs. The operator can switch between the two programs with the push button. Also standard on the 6R Tractors is the battery power-saver feature.

When the engine is off and the outside lights have been left on, this feature is designed to avoid battery run-down. After the lights have been left on for 30 minutes and the key is in the off position, the lights will cycle, or blink on and off five times as an alert. The lights will continue to illuminate for one more minute and then automatically shut off to protect the battery.

CommandCenter programmable time out lighting

CommandCenter programmable time out lighting

CommandCenter programmable lights page

CommandCenter programmable lights page

Beacon lights/hazard warning lights, work light 1 and 2 location on right-hand console

Beacon lights/hazard warning lights, work light 1 and 2 location on right-hand console

Beacon lights/hazard warning lights, work light 1 and 2 location on CommandCenter

Beacon lights/hazard warning lights, work light 1 and 2 location on CommandCenter

Benefits

Additional lights

Overview

Additional lighting is available to match various applications and ensure maximum around-the-clock productivity. Optional LED lighting technology provides extreme brightness and a daylight color output for excellent definition of the field.

The LED lights provide 40 percent greater coverage width and 10 percent more light coverage in the rear. LED lighting packages use 45 percent less amps than standard halogen lights and have an increased life expectancy over HID lights which leads to lower costs of ownership over the life of the tractor.

Overview

One beacon light is mounted on the front of the cab to provide a rotating warning light for road traveling and added visibility.

Benefits

Details

CommandCenter© console TLS Plus provides exclusive front suspension using a hydropneumatic self-leveling system to increase productivity and improve ride dramatically. TLS Plus provides more control over the front suspension of the tractor. In the field, the TLS Plus front suspension maintains ground-to-tire contact, enabling more power to the ground.

Front axle adjustment on CommandCenter

Front axle adjustment on CommandCenter

Auto mode

The TLS Plus reacts to inputs, which provides the best comfort and stability. Inputs include travel speed, implement weight, draft characteristics, and braking activity. The TLS Plus activates whenever the tractor exceeds 1.5 km/h (0.9 mph).

Maximum mode

The suspension is set to maximum hardness, which is preferable for front loader operation. This allows the operator to adjust the suspension for different situations. If the tractor exceeds 35 km/h (22 mph), the hardness is reduced to provide greater driving comfort. When dropping below 25 km/h (15 mph), maximum is reactivated.

Manual mode

This setting can be useful when attaching mounted implements to the front hitch. When activated, the axle settles in its mid position and then can be raised or lowered manually with the touchscreen or shortcut buttons F and G. The manual setting is overridden when the travel speed exceeds 5 km/h (3 mph) and returns to the previously selected setting of automatic or maximum.

|

First link: vertical linkage Two double-acting hydraulic cylinders control the vertical movement of the axle, which leads to excellent sensitivity. |

|

Second link: longitudinal linkage |

|

Third link: lateral linkage This third link holds the axle laterally. These few simple components ensure excellent suspension quality and reliability with reduced maintenance. |

A full stroke of the suspension typically takes 1 second, allowing the system time to distinguish between typical terrain inputs or level changes. This prevents overreactions.

In addition to active central leveling of the suspension, the John Deere TLS Plus adopts a constantly variable rod side pressure by using a closed loop system. When the suspension reacts at a different frequency, which could be detrimental to driver comfort, the system then fine-tunes the rod side pressure, changing the spring stiffness and improving the ride behavior.

*Not available in 6155RH

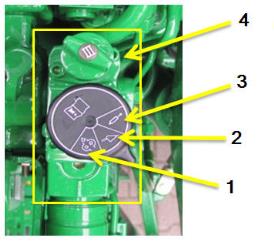

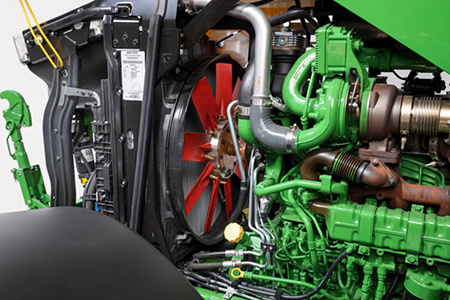

John Deere 6R Series Tractors feature the reliable and proven PowerTech PVS 6.8L and PSS 4.5L and 6.8L engines. These air-to-air aspirated engines deliver a power bulge above rated power to provide excellent torque in demanding applications.

Key features:

PowerTech PSS/PVS engine identification

|

After treatment

|

Turbocharger

|

|

Technology

|

PowerTech PSS 6.8L engine

PowerTech PSS 6.8L engine

Benefits

Details

To match the engine power characteristics and improve the operation economy of the machine, the rated engine speed is 2100 rpm.

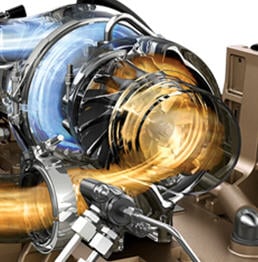

Series turbochargers

Overview

The PowerTech PSS 4.5L and 6.8L utilizes two turbochargers ™ a VGT and a fixed geometry turbocharger, providing the torque rise and engine response needed to meet varying load conditions.

Fresh air is first drawn into the low-pressure fixed geometry turbocharger and compressed to a higher pressure. The compressed, higher pressure air is then drawn into the high-pressure VGT, where the air is further compressed. By splitting the work between two turbochargers, both can operate at peak efficiency and at slower rotating speeds.

PowerTech PSS engine series turbochargers

PowerTech PSS engine series turbochargers

Benefits

VGT

Overview

The VGT is electronically controlled and actuates the turbo vanes as required to maintain peak engine performance.

The turbocharger’s vanes are in the exhaust flow. The opening or closing of the vanes changes the outlet volume and airflow speed against the turbocharger turbine. When exhaust flow is low, the vanes are partially closed. This partial closure increases the pressure against the turbine blades to make the turbocharger spin faster and generate more boost pressure.

The ability to keep the airflow at optimum levels provides more consistent engine boost pressure and the ability to respond to load quickly across the entire engine rpm range. This system is without the turbo lag that can be found on some engines.

PowerTech VGT

PowerTech VGT

Benefits

Air-to-air after cooling

Overview

Air-to-air after cooling lowers the intake manifold air temperature and provides more efficient cooling while reducing cylinder firing pressure and temperatures for greater engine reliability. Since lower temperature air is denser, a higher volume of air flows into cylinders so the engine can meet the increasing horsepower demands. Lowering the intake manifold and cylinder temperatures also aid in lowering the combustion temperature, which lowers the NOx produced as a result.

Benefits

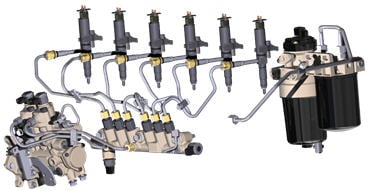

HPCR fuel injection system

Overview

Every PowerTech PSS 4.5L and 6.8L engine utilizes a HPCR fuel system to efficiently supply fuel to injectors. The high-pressure fuel pump instantly responds to requirements for more or less fuel flow or pressure. This electronically controlled, high-pressure pump delivers pressure on demand according to the application requirements. Pressure on demand ensures an efficient injection system resulting in high-injection pressure independent of engine speed.

High-pressure common rail

High-pressure common rail

Benefits

Engine control unit (ECU)

Overview

The ECU uses signal inputs from sensors and pre-programmed performance modeling to control critical engine functions such as fuel quantity, injection timing, air-to-fuel ratio, multiple fuel injections, amount of cooled exhaust gas recirculation (EGR), and a host of other control parameters.

ECU

ECU

Benefits

Details

Each injector is controlled individually by the ECU. The ECU turns the injector on and off during each firing cycle to control the fuel delivery into each cylinder.

Load and speed sensing allow each cylinder’s fuel delivery rate to be adjusted independently at the individual injector. With each injection cycle, the ECU can make the following adjustments on the go:

This management system is connected to the transmission, allowing the engine and transmission to respond simultaneously.

Cold weather and high-altitude compensation are also precisely controlled for quality starts regardless of weather and maximum performance at high elevations. The ECU also features improved diagnostic capabilities. It is faster, has more working memory, and is responsible for monitoring and executing all aspects of the Integrated Emission Control System.

The John Deere Infinitely Variable Transmission (AutoPowr/IVT) utilizes a combination of mechanical and hydrostatic power, providing stepless and continuous power across an infinitely variable range of speeds.

Single-speed lever is used for intuitive and accurate control of ground speeds as slow as 50 m/h (0.03 mph) to 40/50 km/h (25/31 mph). For model year 2015, the transmission has been revised so transport speeds are reached at lower engine rpms, ultimately reducing fuel consumption and in cab noise. Software has also been revised to ensure under acceleration engine rpm is kept to a minimum within the engines peak torque band.Â

AutoPowr/IVT transmission

AutoPowr/IVT transmission

Benefits

Details

| Code | Description |

| 1552 | AutoPowr/IVT ™ 50 km/h |

Details

Â

| Code | Description |

| 1551 | AutoPowr/IVT ™ 40 km/h |

Â

6R in transport

6R in transport

The following features are part of the 50-km/h (31 mph)Â package:

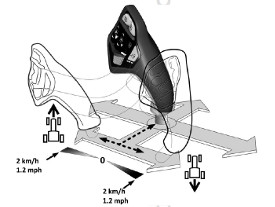

Set-speed adjusting wheel

Overview

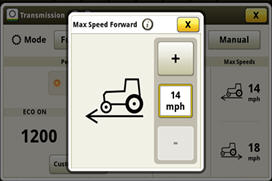

The set-speed adjusting wheel is the rotational thumbwheel located on the speed control lever. The wheel is quick and easy to adjust with the operators thumb and rotates infinitely with no stop or start position. When the operator rotates the thumbwheel, the ground speed of the tractor is increased by 0.2 km/h (0.12 mph) when the tractor is traveling below 20 km/h (12 mph). When the tractor is traveling above 20 km/h (12 mph), the tractor is increased by (1) km/h (0.6 mph). The set speed adjuster is used to set the maximum commanded forward or reverse speed in each speed band.

As the operator moves the lever within or between speed bands, the electronic management system ensures smooth, quick, and powerful acceleration or deceleration, regardless of load or ground speed.

While in motion, the operator can adjust the maximum speed of each speed band. With the lever in band one, the target maximum speed can be adjusted to 20 km/h (12 mph). With the lever in band two, the maximum speed of 40/50 km/h (25/31 mph) can be defined depending on transmission option. When stationary, all set speeds, both forward and reverse, may be adjusted while the left-hand reverser is in the power zero position.

Thumbwheel located on the speed control lever

Thumbwheel located on the speed control lever Lever slot between speed brands

Lever slot between speed brands Drop-down information for set speeds on CommandCenter™ when rotating the thumbwheel

Drop-down information for set speeds on CommandCenter™ when rotating the thumbwheel Set speed indicated in the dashboard

Set speed indicated in the dashboardBenefits

Left-hand reverser

Overview

An easy-to-use left-hand reverser is available in all the AutoPowr/IVT transmissions. The reverser control is located at the 10 o’clock position on the steering column for intuitive control. The left-hand reverser incorporates the following controls:

Pedal mode display on CommandCenter

Pedal mode display on CommandCenter

Benefits

Manual Mode settings

Overview

Manual mode makes the transmission and engine independent of each other. The transmission does not automatically adjust engine rpm to save fuel. This can prove to be useful in applications like loader work where the variability of engine speed based on load is not needed.

Left-hand reverser

Left-hand reverser

Benefits

Electronic hand and foot throttle

Overview

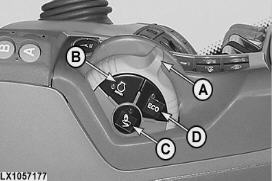

The tractor ground speed is controlled via the accelerator and hand throttle. The engine rpm can be set to a specific ground speed using the hand throttle (A). Button (B) activates and de-activities FieldCruise© (with two available pre-sets), which is an engine rpm limiter.

Â

The specific ground speed set can be set by pressing button (C), this pedal lock feature works like the cruise control on a car (only functions when foot throttle is ordered). Button (D) allows the operator to drive with the minimum target rpm with ECO on.

Â

NOTE: button (D) is only active in custom mode.

Hand throttle

Hand throttle Foot throttle

Foot throttleBenefits

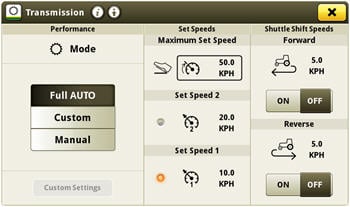

AutoPowr/IVT selector control via CommandCenter

Overview

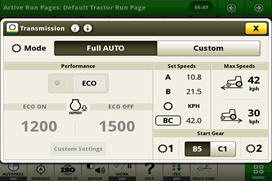

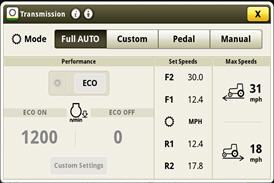

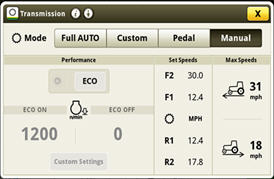

The AutoPowr/IVT application setting employs four modes to take full advantage of the engine-transmission communication: Full auto, custom, pedal and manual.

Full auto mode

Overview

Full auto mode enables the tractor to make adjustments to the transmission operating mode automatically based on the engine and transmission speeds and the load on the tractor. This should be the AutoPowr/IVT setting for 95 percent of all applications.

Full auto mode switches between load control and fuel economy mode seamlessly with no involvement from the operator as conditions and applications change. Fuel economy mode automatically switches off when the power take-off (PTO) is engaged to provide full PTO power. Operators can set the maximum forward and reverse speeds for the tractor in their particular application.

NOTE: Activation ECO is not available in full auto mode.

Full auto screenshot on CommandCenter

Full auto screenshot on CommandCenter

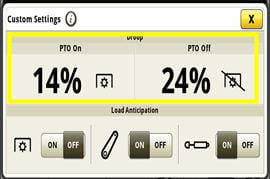

Custom mode

Overview

Custom mode allows the operator to customize the AutoPowr/IVT settings when full auto mode is not desirable. In custom mode, operators can turn ECO on and off. This can either be done by pushing the ECO button on the side of the hand throttle module or by selecting ECO in the transmission settings page of the CommandCenter.

Â

When accelerating with ECO on, the tractor minimizes engine speeds, which reduce acceleration aggressiveness. As a result, ECO on should reduce fuel consumption in lighter, steady loads. In contrast, when accelerating with ECO off, engine speed can be higher aggressively to maximize productivity. The higher engine speeds with ECO off better enable the tractor to quickly recover from sudden load increases and not lose as much ground speed when load increases occur.

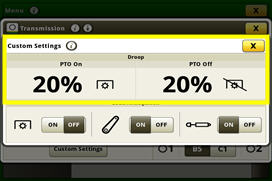

In custom mode, the engine droop settings can be defined between 4 percent and 30 percent with PTO on and off. The higher the droop percentage the more the engine rpm will be reduced when pulling before a transmission ratio change is made

Customizing speed of direction on CommandCenter

Customizing speed of direction on CommandCenter Droop setting on CommandCenter screen

Droop setting on CommandCenter screenBenefits

Pedal mode settings

Overview

Pedal mode allows the operator to change the tractor’s ground speed independently from the engine speed. The ground speed is controlled through use of the foot pedal while the hand throttle determines engine speed. Maximum ground speed is determined by the location of the speed control lever in the speed band.

Â

Operators can lock-in a desired ground speed, without pressure on the foot pedal, using the pedal lock button (as described above). To unlock the foot pedal, the operator can tap the foot pedal, press the lock button, or press the brake pedal. When releasing the foot pedal, the vehicle decelerates to a safe creep speed. To come to a complete stop, the brake pedal should be depressed.

Operation just presses brake pedal to stop the tractor

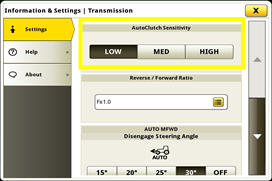

Operation just presses brake pedal to stop the tractor The Auto clutch sensitivity change on CommandCenter

The Auto clutch sensitivity change on CommandCenterBenefits

Torque

Overview

The AutoPowr/IVT is a combination of mechanical and hydraulic components that are capable of providing low speed with extremely high levels of torque:

Creeper mode

Creeper mode is a standard feature on AutoPowr/IVT. Down to 50 m/h (164 ft/h) the creeper mode is activated when the selected speed is below 2.1 km/h (1.3 mph) in set position 1.

When the tractor moves below 600 m/h (1968 ft/h), the engine speed is independent of travel speed. This allows the operator to choose the engine speed that best fits the task (rated speed for hydraulic or PTO usage, or low idle for fuel-saving operation). No additional power is needed.

Manual mode display on CommandCenter

Manual mode display on CommandCenter

Load anticipation feature

Overview

The load anticipation feature allows the AutoPowr/IVT to predict how much load the engine expects from the activation of the hitch or a particular SCV function.

In Full Auto Mode, all load anticipation features are active. In custom mode, they can be turned on or off in the custom settings page. When a SCV or the hitch is activated, the engine speed is raised to 1500 rpm (as long as the commanded throttle position is over this value). This creates a boost in engine power, which improves hydraulic performance and prepares the engine for potential load situations, returning an implement to work for example.

Â

Also added is PTO load anticipation. If it is turned off, the engine does not react to PTO engagement, and engine speed is controlled purely based on load , If turned on (in custom) when the PTOÂ is engaged, the engine rpm will rise to throttle position or pre-defined PTO cruise setting.

Load anticipation display on CommandCenter

Load anticipation display on CommandCenter

Benefits

Forward/Reverse relationship

Overview

Similar to the AutoQuad PLUS transmission, the AutoPowr/IVT can also adjust the forward/reverse speed ratio. The reverse speeds can be set to a maximum of 30 percent higher and 70 percent lower than forward speeds but only in range 1. In range 2, the forward-to-reverse speed ratio is 1:1, up to 22 km/h (14 mph). Above that, the reverse speeds will only go up to 30 km/h (19 mph).

Section of forward/reverse relationship via CommandCenter

Section of forward/reverse relationship via CommandCenter

Brake with integrated Auto Clutch function

Overview

With the AutoPowr/IVT, no clutching is required to stop the tractor. After the brakes are released, the tractor automatically accelerates back to its previous speed (if using hand throttle) The effect of Auto Clutch can also be set via the operator CommandCenter.

ComfortView cabs feature a modern, automotive-style instrument panel as base equipment. The instrument pod has two large analog dials for engine and tractor speed, as well as two smaller dials that display fuel level, DEF level, and coolant temperature. The steering column and dash are adjustable to suit the operator's needs. The column tilts toward the operator and a lever on the left-hand side allows for the column to telescope out to the desired level.

A dimming mode automatically reduces the brightness of the instrument illumination when the tractor lights are used.

Cab and controls 6R Tractor

Cab and controls 6R Tractor

Instrumentation control panel

Overview

The instrumentation panel has a row of information and warning lights across the bottom to monitor all important tractor functions. A three-stage warning system first gives information, then gives warnings,and finally gives a stop alarm to prevent damage from occurring in the event of a component malfunction. An integrated power take-off (PTO) over-speed warning is incorporated into the diagnostics to ensure proper operation.

Instrumentation control panel

Instrumentation control panel

Dash instrument panel controls include:

| Left side | Right side |

| Left-hand reverser | Two-speed and optional intermittent wiper |

| High-/low-beam switch | Key start/stop |

| Hazard switch | Road/work lights on/off |

| Turn signals/horn |

Overhead storage compartment

Overhead storage compartment CommandARM™ storage compartment

CommandARM™ storage compartmentCommandARM controls

Overview

The 6R Series features a redesigned CommandARM with all key vehicle functions in one place.

The updated CommandARM layout is only available with Infinitely Variable Transmission (IVT™) and DirectDrive transmissions.

The base 17.8 cm (7-in.) (4100 CommandCenter) or optional 25.4 cm (10-in.) (4600 CommandCenter™) display is fully integrated on to CommandARM and offers fast adjustment of additional tractor functions.

The CommandARM design allows for 37.5 degrees of total seat swivel and adjustable positioning matching the operator’s preference. (30 degrees right and 7.5 degrees left)

Hydraulic and hitch controls utilize fingertip paddle pods for raise/lower and extend/retract functions. The CommandARM offers up to a maximum of six electronic selective control valves (E-SCVs) (without electronic joystick). The optional electrical joystick replaces fingertip paddle pods for control of selective control vales (SCVs) and allows for programmable hydraulic functionality according to operator preference.(A maximum of five E-SCVs can be ordered with the electronic joystick).

Controls for radio, lights, rotary beacon, and hazard flashers are located to the center right on the CommandARM along with PTO for front (if equipped) and rear PTO. Additionally, located on the right side of the CommandARM is an encoder wheel, which allows for finite positioning of the rear 3-point hitch. Three buttons near the encoder for set lock and return to height. Adjustment knobs for the 3-point hitch are located under the cover for the CommandARM storage compartment and allow for adjustment of the rate of drop, hitch height limit, and depth control.

The transmission control and throttle are placed on the left side of the CommandARM closest to the operator for convenient setting and adjustment. The throttle design incorporates buttons which control engine cruise speed, pedal lock/cruise control, and transmission Eco settings (for more information refer to the AutoPowr™ or DirectDrive transmissions pages).

Located just to the right of the throttle is the auto-steer activation button and four sequence controls for iTEC™ functions. Behind the iTEC sequence controls are buttons which control the activation and deactivation of MFWD and differential lock.

Differential lock can also be activated by foot switch on the cab floor. A new feature in the 6R Series Tractor is auto steering angle dependent differential lock button.

Operators can easily identify controls by icons located near levers, and each functional area is color-coded.

2056- ComfortView cab with CommandARM

2056- ComfortView cab with CommandARM Close up of controls on CommandARM

Close up of controls on CommandARM Optional integrated crossgate joystick

Optional integrated crossgate joystick New hand throttle features

New hand throttle features 3-point hitch control layout

3-point hitch control layout Integrated differential lock features

Integrated differential lock featuresBenefits

Right-hand console controls

Overview

The right-hand control console is angled for operator comfort and ease of operation. The design of the right-hand console is controlled by the type of SCVs chosen.

Mechanically actuated valves are controlled by traditional levers while electronically actuated valves are controlled by fingertip paddle pods. Controls for the ComfortView cab are grouped by function on the right-hand console.

The modular console panel provides individual access to hand throttle, transmission controls, MFWD switch (if equipped), hitch command console, load/draft control, SCV, and PTO controls.

The console is also the location of the CommandCenter. The CommandCenter allows the operator to customize important tractor functions.

This option requires a PowrQuad™ or AutoQuad™ transmission.

ComfortView cab right-hand console (AutoQuad transmission is shown)

ComfortView cab right-hand console (AutoQuad transmission is shown) Hitch control module on right-hand console

Hitch control module on right-hand console

| Cab packages | Economy right-hand console | Standard right-hand console | Standard CommandARM | Premium right-hand console | Premium CommandARM | Premium right-hand console cab suspension | Premium CommandARM cab suspension |

| Package code | 2051 | 2061 | 2062 | 2065 | 2066 | 2069 | 2070 |

| One panorama door (left hand only) | X | X | X | ||||

| Two panorama doors (left-hand and right-hand sides) |

| X | X | X | X | ||

Air seat (Sears) | X | X | X | X | X | ||

| Deluxe air seat (Grammer® DDS) |

| X | X | ||||

| Instructional seat | X | X | X | X | X | X | |

| Bottle holder | X | X | X | X | X | X | |

| Mirrors - right hand and left hand - manually adjustable and telescopic | X | X | X | ||||

| Wide-angle mirrors - right hand and left hand - electrically adjustable |

| X | X | X | X | ||

| Front sun visor | X | X | X | ||||

| Front and rear roller blind |

| X | X | X | X | ||

| Rear wiper and washer | X | X | X | X | X | X | |

| Manual temperature controls | X | X | X | ||||

| Automatic temperature controls | X | X | X | X | |||

| Hydraulic cab suspension |

| X | X |

Grammer is a trademark of Grammer Aktiengesellschaft Joint Stock Company.

M-SCV controls on the right-hand console

M-SCV controls on the right-hand console E-SCV controls on the right-hand console

E-SCV controls on the right-hand consoleBenefits

Overview

The 6R Tractors have seven cab packages designed to match customers’ operations. There are three levels of comfort - economy, standard, and premium. There are two control configurations available, right-hand console for the PowrQuad PLUS or AutoQuad PLUS transmissions and CommandARM for the IVT™ and DirectDrive transmissions. There is an option for hydraulic cab suspension for the premium package. Below is a chart showing the available packages and what is included in each package.

Benefits

Details

Base features in all cab packages:

The DirectDrive transmission combines the efficiency benefits of a manual shift transmission with easy handling similar to the AutoPowr™/IVT™ transmission. DirectDrive utilizes unique double-clutch technology giving 6R operators more driving comfort.

Since this is a mechanical transmission, it provides smooth shifting between gears with high efficiency. Smooth shifting is achieved by excellent modulation between the dual clutches in combination with engine rpm management to speed match the next gear.

DirectDrive uses efficiency manager to automatically change up gears and throttle back, similar to how AutoPowr varies its ratio to achieve minimum engine rpm with a higher transmission ratio.

The best of both worlds - efficiency and comfort

The best of both worlds - efficiency and comfortBenefits

Details

| Code | Description | Available for | Information |

| 1530 | DirectDrive – 40 km/h (25 mph) | 6175R, 6195R, 6215R | Double clutch transmission, 40 km/h (25 mph) at reduced engine speed |

The DirectDrive transmission consists of the range box, the dual-path module, and the PowrReverser™.

Range box

The range box in the 6R Series consists of three ranges perfectly suited for agricultural applications.

Changing from ranges is quick and simple and due to its adaptation to agricultural applications, it is hardly ever required in the field. Less range shifting means fewer torque interruptions.

40 km/h (25 mph) during transportation

40 km/h (25 mph) during transportation![Ideal ranges for all needs (40 km/h [25 mph] version)](https://salesmanual.deere.com/sales/salesmanual/images/NA/tractors/6r/range_40.jpg) Ideal ranges for all needs (40 km/h [25 mph] version)

Ideal ranges for all needs (40 km/h [25 mph] version)Dual-path module

Overview

The dual path module includes the eight PowerShift gears, available in all three ranges. The PowerShift gears can change automatically, creating a very efficient drive strategy to save fuel and reduce noise.

The main technical innovation is the use of two clutches in one transmission. This system allows very fast shifting between gears and is highly efficient. The second gear is already lined up, ready to go, and just waiting for the change command to be given.

Dual-path module PowerShift gears

Dual-path module PowerShift gearsLeft-hand reverser

Overview

An easy-to-use left-hand reverser is available in all the DirectDrive transmissions. The reverser control is located at the 10 o’clock position on the steering column for intuitive control. The left-hand reverser incorporates the following controls:

Left-hand reverser

Left-hand reverserBenefits

Electronic hand and foot throttle

Overview

The tractor ground speed is controlled via the accelerator and hand throttle. The engine rpm can be set to a specific ground speed using the hand throttle (A). Button (B) activates and de-activates FieldCruise™ (with two available pre-sets), which is an engine rpm limiter. The specific ground speed can be set by pressing button (C), this pedal lock feature works like the cruise control on a car. Button (D) allows the operator to drive with the minimum target rpm with eco on; note button (D) is only active in custom mode.

Hand throttle

Hand throttle Foot throttle

Foot throttleBenefits

Gear and range views in display

Overview

In the DirectDrive transmission, the selected range and selected PowerShift gear can be viewed in the dashboard.

Similar to the AutoPowr/IVT transmission control and display, the DirectDrive transmission has the red lights inside the speed display so the operator can see how fast the tractor will go at full commanded speed. This is adjusted using the speed wheel on top of the shift control lever.

Ranges A, B, C, and PowerShift steps are displayed on the dashboard

Ranges A, B, C, and PowerShift steps are displayed on the dashboard Set speed indicated in the dashboard

Set speed indicated in the dashboardCab ComfortView™ Premium Plus – CommandARM™

Overview

The DirectDrive transmission can only be equipped on the CommandARM.

DirectDrive control unit

DirectDrive control unit Custom mode settings on CommandARM

Custom mode settings on CommandARMIf the tractor runs under full load, the gear shifting can be customized with this setting.

In custom mode the engine droop settings can be defined between 6 percent and 40 percent with power take-off (PTO) on and off. The higher the droop percentage, the more the engine rpm will be reduced when pulling before a transmission down shift is made.

A speed droop expressed as percentage of full engine speed can be chosen:

Control unit integrated into CommandARM

Control unit integrated into CommandARMDirectDrive control unit

Overview

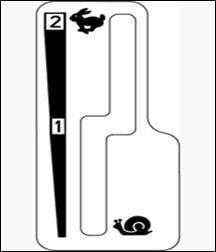

The DirectDrive control unit consists of the speed control lever, which has an ergonomically integrated set speed adjusting wheel. The set speed adjusting wheel is a rotational thumbwheel located on the speed control lever. The wheel is quick and easy to adjust with the thumb and rotates infinitely with no stop or start position. When the operator rotates the thumbwheel, the maximum commanded forward/reverse speed is set. Also integrated are three buttons to set the ranges.

Thumbwheel located on the speed control lever

Thumbwheel located on the speed control lever Manual mode

Overview

In this mode, the operator manually changes the gears. Put the lever up (+) to select a higher gear and put the lever down (-) to select a lower gear. In this mode the throttle and transmission are independent, efficiency manager is only effective in auto mode.

DirectDrive speed lever in manual mode

DirectDrive speed lever in manual modeFull auto mode

Overview

If the lever is put in the right position, the auto mode is selected and the transmission shifts automatically, depending on the engine load and speed.

DirectDrive speed lever in full auto mode

DirectDrive speed lever in full auto modeCommandCenter™ settings – Full auto mode

Overview

Full auto mode enables the tractor to make adjustments to the transmission operating mode automatically, based on the engine and transmission speeds and the load on the tractor.

Full auto mode switches between load control and fuel economy mode seamlessly, with no involvement from the operator, as conditions and applications change. Fuel economy mode automatically switches off when the PTO is engaged to provide full PTO power. Operators can set the maximum forward and reverse speeds for the tractor in their particular applications.

Full auto mode on CommandARM

Full auto mode on CommandARMCommandCenter setting - custom mode

Overview

Custom mode allows the operator to customize the DirectDrive settings if full auto mode is not desirable.

PTO settings

PTO settings Eco mode off

Eco mode off Eco mode on

Eco mode on Load anticipation feature

Load anticipation featureBrake with integrated AutoClutch function

Overview

By depressing both brake pedals simultaneously, the tractor decelerates until it comes to a full stop. No clutching is required. After the brakes are released, the tractor will start to crawl forward.

AutoClutch function is integrated ™ no clutching required

AutoClutch function is integrated ™ no clutching requiredTo control a rear implement, up to six SCVs or five SCVs plus Power Beyond can be ordered (6145R-6250R). For (6110R- 6130R) up to five SCVs or four SCVs plus Power Beyond can be ordered. The SCVs can be controlled electrically. Up to four mechanical SCVs are available, in combination with Power Beyond. All mechanical or electrical SCVs feature four positions - neutral, raise, lower, and float.

Benefits

| Code | Description | Information | Availability |

| 3312 | Two mechanical SCVs ™ premium | Premium couplers with high-pressure relief lever. Two mechanical SCVs 450 Series. Only in combination with PowrQuad© Plus transmission or AutoQuad© Plus transmission. Only available on 6110R - 6130R. |

6110R, 6120R, 6130R |

| 3332 | Three mechanical SCVs - premium | Premium couplers with high-pressure relief lever. Only in combination with PowrQuad Plus or AutoQuad Plus. | 6110R, 6120R, 6130R, 6145R, 6155R, 6175R, 6195R, 6215R |

| 3311 | Two electronic SCVs - premium | Premium couplers with high-pressure relief lever. | 6110R, 6120R, 6130R |

| 3331 | Three electronic SCVs - premium | Premium couplers with high-pressure relief lever. | 6110R, 6120R, 6130R, 6145R, 6155R, 6175R, 6195R, 6215R, 6230R, 6250R |

| 3341 | Four electronic SCVs - premium | Premium couplers with high-pressure relief lever. | 6110R, 6120R, 6130R, 6145R, 6155R, 6175R, 6195R, 6215R, 6230R, 6250R NOTE: Not available for 6155RH. |

| 3351 | Five electronic SCVs ™ premium | Premium couplers with high-pressure relief lever. When ordered with right-hand console, (code 2055) also electrical joystick (code 841L) for operation of rear SCVs or electrical midstack SCV (code 8922, 8923, 8914 or 8915) is required. A maximum of four SCVs can be operated via paddle pot at right-hand console. | 6110R, 6120R, 6130R, 6145R, 6155R, 6175R, 6195R, 6215R, 6230R, 6250R NOTE: Not available for 6155RH. |

| 3361 | Six electronic SCVs ™ premium | Premium couplers with high-pressure relief lever. Not with right-hand console (code 2055). Not in combination with electrical joystick (code 841L) and any option with electrical joystick. | 6145R, 6155R, 6175R, 6195R, 6215R, 6230R, 6250R NOTE: Not available for 6155RH. |

Overview

The tractor may be equipped with one type of mechanical control valves: premium (450 Series).

Premium-couplers control valves also have an additional lock function (position 3), which holds the control lever in the raise or lower position until the pressure in the oil circuit has reached a predetermined value (e.g., when the control cylinder has reached its end position).

In position 2, the control lever returns to neutral as soon as it is released and is the setting for normal hydraulic operation.

If an implement is connected, pressure connection has to be connected to the lower coupler. With standard SCVs, a valve prevents sudden loss of pressure caused by leakage when the engine is shut off.

On premium SCVs, the likelihood of leakage is further diminished.

Premium mechanical control valve (premium)

Premium mechanical control valve (premium)

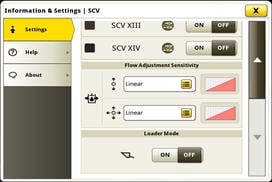

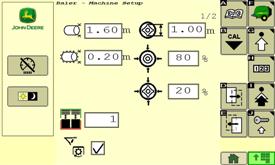

Overview

The tractor may be equipped with the premium (450 Series) control valves. All main characteristics can be controlled by the CommandCenter© display.

CommandCenter hydraulics option

CommandCenter hydraulics option

3351 ™ five electronic SCVs (five SCV premium)

3351 ™ five electronic SCVs (five SCV premium)

3361 ™ six electronic SCVs (six SCV premium)

3361 ™ six electronic SCVs (six SCV premium)

E-SCV controls on the right-hand console

E-SCV controls on the right-hand console

M-SCV controls on the right-hand console

M-SCV controls on the right-hand console

E- SCV controls on CommandARM© controls

E- SCV controls on CommandARM© controls

E-SCV controls on optional joystick (reconfigurable)

E-SCV controls on optional joystick (reconfigurable)

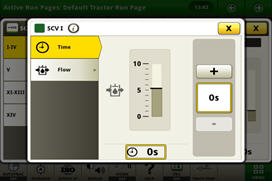

Hydraulic set up

Shortcut button right-hand console

Overview

Simply push the hydraulic symbol on the right-hand side console or the CommandCenter and the CommandCenter display shows a setup menu to:

Hydraulic shortcut button on right-hand console

Hydraulic shortcut button on right-hand console

Hydraulic shortcut button CommandCenter

Hydraulic shortcut button CommandCenter

Detent setup

Overview

Detent setup

Detent setup

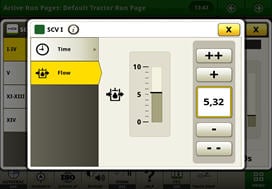

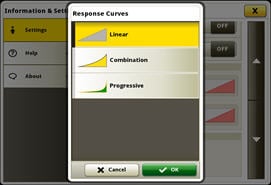

SCV flow setup

Overview

SCV flow rate can be programmed between 0.04 and 10 allowing fine tuning for implements with different hydraulic requirement.

Behavior can be set between linear (red), progressive (green), or a combination (yellow) for exact flow modulation and precise valve management.

Flow setup

Flow setup

Three flow options

Three flow options

Flow characteristic setup

Flow characteristic setup

Combination is an intermediate stage between the two settings listed above.

A single manual action; system manages the rest

A single manual action; system manages the rest TBA awards

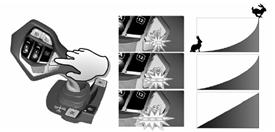

TBA awardsThe optional Tractor-Baler Automation (TBA) makes baling easy. This exclusive system manages most of the baling process and gives the customer the following advantages:

When used with a John Deere ISOBUS tractor, electric selective control valve (E-SCV), and (IVT™) transmission, the system will be able to:

The only action remaining is to forward reverser and manage the steering.

If the John Deere tractor is not equipped with IVT but has E-SCV and ISOBUS, opening and closing can be automated.

A single touch on SCV, brakes, or reverser will disengage the automation. In the same way, automated open/close can be momentarily stopped when unloading in hilly conditions.

Tractor-Implement Automation is an exclusive green on green advantage. This advanced technology option has won awards at SIMA and Agritechnica farm equipment show in Europe, a true cost/value guarantee.

NOTE: to run through fully automated mode, a John Deere Isobus tractor with E-SCV and IVT is required. A baler activation key and a tractor activation key (different) have to be ordered.

Plug in and bale with ISOBUS

Plug in and bale with ISOBUS ISOBUS certified = compatibility guarantee

ISOBUS certified = compatibility guaranteeThe 990 and 960 Balers offer ISOBUS compatibility as base equipment. This standardized communication not only allows the use of John Deere Greenstar2 1800, 2600, or 2630 Displays, but also the use of other ISOBUS conform competitive monitors.

Adapter harnesses for non-ISOBUS tractors are available.

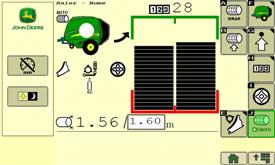

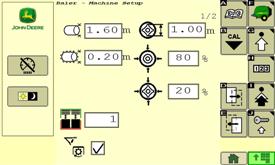

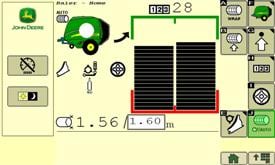

Main page with simple and clear pictograms

Main page with simple and clear pictograms Bale or soft core density adjustments

Bale or soft core density adjustmentsThe Baler interface displays information that is needed. The 900 Series monitors provide all required information:

Adjustments can also be managed from the operators station:

Greenstar2 1800 Display ordered with the baler

Greenstar2 1800 Display ordered with the baler

The 900 Series Balers can be teamed with all ISOBUS certified displays. The Greenstar2 1800 monitor can be ordered with the baler to match traditional baling requirements. When not baling this display can be used for other functions such as guidance and spraying applications when connected to an appropriate receiver and implement.

GreenStar3 2630 fits the most demanding user needs

GreenStar3 2630 fits the most demanding user needs

The 960 and 990 Balers can be ordered without a monitor for customers who already have an ISOBUS display, or for those who search more advanced application (field management). Displays other than John Deere Greenstar2 1800 can be purchased through Ag Management Solutions (AMS) pages.

The Generation 4 CommandCenter creates the primary user interface for 6R Tractors. The Generation 4 CommandCenter provides an excellent, user-savvy operating experience.

Producers can also use a variety of implements with the Generation 4 CommandCenter as it is ISOBUS virtual terminal (VT) capable.

Expect machine productivity gains, along with increased operator confidence, thanks to a simple, customizable interface. The reliability of the Generation 4 CommandCenter also aids in optimal operating experience and maximizes uptime.

4200 CommandCenter 21.3-cm (8.4-in.) display

4200 CommandCenter 21.3-cm (8.4-in.) display

4600 CommandCenter 25.4-cm (10-in.) display

4600 CommandCenter 25.4-cm (10-in.) display

Benefits

Details

| Code | Description |

| 1947 | 4200 Processor (21.3-cm [8.4-in.] display only) |

| 1946 | 4600 Processor (25.4-cm [10-in.] display only) |

| Code | Description |

| 1829 | 21.3-cm (8.4-in.) CommandCenter display (4200 Processor only) |

| 1822 | 25.4-cm (10-in.) CommandCenter display (4600 Processor only) |

| Code | Description |

| 1867 | Less application |

| 1851 | CommandCenter AutoTrac© activation |

| 1858 | 4200 Section Control and Data Sync activation plus CommandCenter AutoTrac activation |

| 1857 | 4600 CommandCenter Premium Activation 3.0 |

| 1861 | 4600 CommandCenter Automation Activation 1.0 |

| 186S | 4600 CommandCenter Automation Activation 3.0 |

NOTE: CommandCenter AutoTrac activation stays with the tractor.

NOTE: 6155RH only available with code 1867.

Layout Manager selection page

Layout Manager selection page

Layout Manager module build

Layout Manager module build

The Generation 4 CommandCenter features a modular-designed layout manager so an operator can easily create the structure that meets the operator’s demands. From the factory, machines are equipped with standard run pages. An unlimited amount of run pages can be added to the Generation 4 CommandCenter based on operator preference or operational needs. Toggling between run pages is as easy as swiping the screen or using the arrow buttons on the top right portion of the title bar.

Users and access

Users and access allow the owner to lock out certain functions to prevent operators from accessing or changing settings. Lock-out functions are managed with an owner-defined four-digit code.

Lockout features are available for:

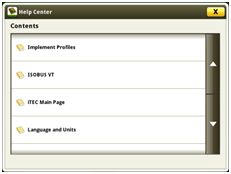

On-screen help and diagnostic text

There are a few different ways to get meaningful on-screen help when navigating the Generation 4 CommandCenter. Operators can find the help icon on the shortcut bar on the bottom of every page. This icon gives detailed information on everything from tractor operation to application information. Simply select the help icon and navigate to the information section that is needed.

Help center main page

Help center main page

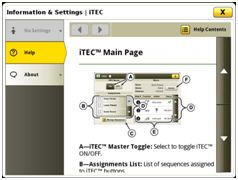

Additionally, application-based help is also available in all locations of the CommandCenter. Simply click on the (i) icon available on the title bar and it will lead directly to more information on the application currently being used.

Context-based help iTEC© main page

Context-based help iTEC© main page

Diagnostic text and information are available for better understanding of whether applications are operating as directed.

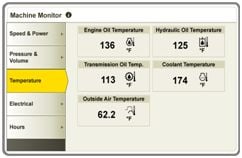

Machine monitor page

Machine monitor page

The machine monitor application provides the user instantaneous readings about the status or condition of the machine. Values shown in the machine monitor vary by application, but typically include parameters like engine speed, coolant temperature, and ground speed. The machine monitor supports run page modules in the layout manager, allowing the user to populate specific machine parameters directly to a run page.

NOTE: The machine monitor application replaces part of the Universal Performance Monitor in previous machines.

Work monitor page

Work monitor page

The work monitor application displays the performance information about the task being performed by the machine. The user is shown averages, totals, and productivity of the machine, such as area worked, average working speed, and fuel usage. The values of the work monitor can be reset by the user at any time. Specific values of the work monitor can be configured by the user to be shown on a run page.

NOTE: The work monitor application replaces part of the universal performance monitor in previous machines.

Video capability

Tractors with a 4200 CommandCenter are equipped with one video input and tractors with a 4600 CommandCenter have two video inputs (one port to connect two cameras via a Y harness). The operator can set a variety of triggers, including reverse, PTO, hitch, and selective control valve (SCV) levers to activate the camera. The image will then appear on the CommandCenter display. The camera (video observation system) is available through John Deere Parts and Ag and Industrial (A & I) Products.

John Deere Generation 4 CommandCenter processors

A Generation 4 CommandCenter is made up of a processor and a display. Two processor options are available for the Generation 4 CommandCenter.

The 4600 Processor is the premium processor. Available features with the premium processor include:

25.4-cm (10-in.) 4600 CommandCenter display

25.4-cm (10-in.) 4600 CommandCenter display

The 4200 Processor is base equipment on all 6R Tractors. It offers:

| Tractors | 4600 Processor | 4200 Processor |

| 6R | Option | Standard |

Display options

Generation 4 CommandCenter displays are available in the following configurations:

For those wanting to maximize their viewing real estate, the 25.4-cm (10-in.) touchscreen color display is an excellent choice. With the 25.4-cm (10-in.) display, the title bar and all shortcut keys can always be viewed. Operators can monitor more items at once on the 25.4-cm (10-in.) touchscreen display.

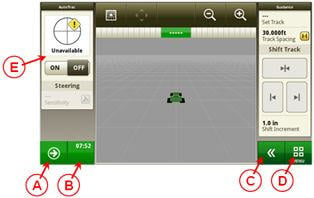

John Deere 4200 CommandCenter

John Deere 4200 CommandCenter

A. Next run page

B. Status center

C. Expand shortcut keys

D. Menu

E. Run page

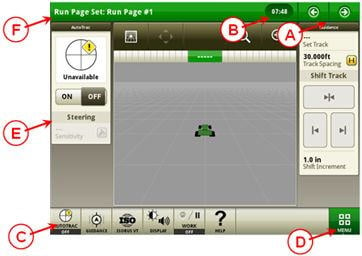

John Deere 4600 CommandCenter

John Deere 4600 CommandCenter

A. Next and previous run page

B. Status center

C. Shortcut keys

D. Menu

E. Run page

F. Title bar

The John Deere Infinitely Variable Transmission (AutoPowr/IVT) utilizes a combination of mechanical and hydrostatic power, providing stepless and continuous power across an infinitely variable range of speeds.

Single-speed lever is used for intuitive and accurate control of ground speeds as slow as 50 m/h (0.03 mph) to 40/50 km/h (25/31 mph). In model year 2015, the transmission was revised so transport speeds are reached at lower engine rpms, ultimately reducing fuel consumption and in cab noise. Software has also been revised to ensure under acceleration engine rpm is kept to a minimum within the engines peak torque band.

AutoPowr/IVT transmission

AutoPowr/IVT transmission

Benefits

Details

NOTE: Not available in 6155RH.

| Code | Description |

| 1558 | AutoPowr/IVT ™ 50 km/h (31 mph) |

Details

NOTE: Not available in 6155RH.

| Code | Description |

| 1557 | AutoPowr/IVT ™ 40 km/h (25 mph) |

6R in transport

6R in transport

The following features are part of the 50 km/h (31 mph) package:

Set-speed adjusting wheel

Overview

The set-speed adjusting wheel is the rotational thumbwheel located on the speed control lever. The wheel is quick and easy to adjust with the operator’s thumb and rotates infinitely with no stop or start position. When the operator rotates the thumbwheel, the ground speed of the tractor is increased by 0.2 km/h (0.12 mph) when the tractor is traveling below 20 km/h (12 mph). When the tractor is traveling above 20 km/h (12 mph), the tractor is increased by (1) km/h (0.6 mph). The set speed adjuster is used to set the maximum commanded forward or reverse speed in each speed band.

As the operator moves the lever within or between speed bands, the electronic management system ensures smooth, quick, and powerful acceleration or deceleration, regardless of load or ground speed.

While in motion, the operator can adjust the maximum speed of each speed band. With the lever in band one, the target maximum speed can be adjusted to 20 km/h (12 mph). With the lever in band two, the maximum speed of 40/50 km/h (25/31 mph) can be defined depending on transmission option. When stationary, all set speeds, both forward and reverse, may be adjusted while the left-hand reverser is in the power zero position.

Thumbwheel located on the speed control lever

Thumbwheel located on the speed control lever

Lever slot between speed brands

Lever slot between speed brands

Drop-down information for set speeds on CommandCenter© display when rotating the thumbwheel

Drop-down information for set speeds on CommandCenter© display when rotating the thumbwheel

Set speed indicated in the dashboard

Set speed indicated in the dashboard

Benefits

Left-hand reverser

Overview

An easy-to-use left-hand reverser is available in all the AutoPowr/IVT transmissions. The reverser control is located at the 10 o’clock position on the steering column for intuitive control. For tractors without the CommandPRO© joystick, the left-hand reverser incorporates the following controls:

Left-hand reverser

Left-hand reverser

For tractors with CommandPRO, the left-hand reverser incorporates only forward and reverse direction selection and the lever is self-centering. The park (P) and neutral (N) positions can be selected on the CommandPRO.

Left-hand reverser if equipped with CommandPRO

Left-hand reverser if equipped with CommandPRO

Benefits

Electronic hand and foot throttle

Overview

The tractor ground speed is controlled via the accelerator and hand throttle. The engine rpm can be set to a specific ground speed using the hand throttle (A). The following functions are available for tractors without CommandPRO:

Hand throttle

Hand throttle

The following functions are available for tractors with CommandPRO:

Hand throttle when equipped with CommandPRO

Hand throttle when equipped with CommandPRO

Foot throttle

Foot throttle

Benefits

AutoPowr/IVT selector control via CommandCenter display

Overview

The AutoPowr/IVT application setting employs four modes to take full advantage of the engine-transmission communication: full AUTO, custom, pedal and manual.

Full AUTO mode

Overview

Full AUTO mode enables the tractor to make adjustments to the transmission operating mode automatically, based on the engine and transmission speeds and the load on the tractor. This should be the AutoPowr/IVT transmission setting for 95 percent of all applications.

Full AUTO mode switches between load control and fuel economy mode seamlessly, with no involvement from the operator, as conditions and applications change. Fuel economy mode automatically switches off when the power take-off (PTO) is engaged to provide full PTO power. Operators can set the maximum forward and reverse speeds for the tractor in their particular application.

NOTE: Activation ECO is not available in full auto mode.

Full auto screenshot on CommandCenter display

Full auto screenshot on CommandCenter display

Custom mode

Overview

Custom mode allows the operator to customize the AutoPowr/IVT transmission settings when full auto mode is not desirable. In custom mode, operators can turn ECO on and off. This can either be done by pushing the ECO button on the side of the hand throttle module or by selecting ECO in the transmission settings page of the CommandCenter display. When accelerating with ECO on, the tractor minimizes engine speeds, which reduce acceleration aggressiveness. As a result, ECO on should reduce fuel consumption in lighter, steady loads. In contrast, when accelerating with ECO off, engine speed can be higher aggressively to maximize productivity. The higher engine speeds with ECO off better enable the tractor to quickly recover from sudden load increases and not lose as much ground speed when load increases occur.

In custom mode, the engine droop settings can be defined between 4 percent and 30 percent with PTO on and off. The higher the droop percentage, the more the engine rpm will be reduced when pulling before a transmission ratio change is made.

Customizing speed of direction on CommandCenter display

Customizing speed of direction on CommandCenter display

Droop setting on CommandCenter screen

Droop setting on CommandCenter screen

Benefits

Pedal mode settings

Overview

Pedal mode allows the operator to change the tractor’s ground speed independently from the engine speed. The ground speed is controlled through use of the foot pedal while the hand throttle determines engine speed. Maximum ground speed is determined by the location of the speed control lever in the speed band. Operators can lock-in a desired ground speed without pressure on the foot pedal using the pedal lock button (as described above). To unlock the foot pedal, the operator can tap the foot pedal, press the lock button, or press the brake pedal. When releasing the foot pedal, the vehicle decelerates to a safe creep speed. To come to a complete stop, the brake pedal should be depressed.

Pedal mode display on CommandCenter display

Pedal mode display on CommandCenter display

Benefits

Manual mode settings

Overview

Manual mode makes the transmission and engine independent of each other. The transmission does not automatically adjust engine rpm to save fuel. This can prove to be useful in applications like loader work, where the variability of engine speed based on load is not needed.

Manual mode display on CommandCenter display

Manual mode display on CommandCenter display

Load anticipation feature

Overview

The load anticipation feature allows the AutoPowr/IVT transmission to predict how much load the engine expects from the activation of the hitch or a particular SCV function.

In full AUTO mode, all load anticipation features are active. In custom mode, they can be turned on or off in the custom settings page. When an SCV or the hitch is activated, the engine speed is raised to 1500 rpm (as long as the commanded throttle position is over this value). This creates a boost in engine power which improves hydraulic performance and prepares the engine for potential load situations (for example, returning an implement to work). Also added is PTO load anticipation. If it is turned off, the engine does not react to PTO engagement and engine speed is controlled purely based on load. If turned on (in custom), when the PTO is engaged, the engine rpm will rise to throttle position or pre-defined PTO cruise setting.

Load anticipation display on CommandCenter display

Load anticipation display on CommandCenter display

Benefits

Forward/Reverse relationship

Overview

Similar to the AutoQuad© PLUS transmission, the AutoPowr/IVT transmission can also adjust the forward/reverse speed ratio. The reverse speeds can be set to a maximum of 30 percent higher and 70 percent lower than forward speeds, but only in range 1. In range 2, the forward-to-reverse speed ratio is 1:1, up to 22 km/h (14 mph). Above that, the reverse speeds will only go up to 30 km/h (19 mph).

Section of forward/reverse relationship via CommandCenter display

Section of forward/reverse relationship via CommandCenter display

Brake with integrated AutoClutch function

Overview

With the AutoPowr/IVT transmission, no clutching is required to stop the tractor. After the brakes are released, the tractor automatically accelerates back to its previous speed (if using hand throttle). The effect of AutoClutch can also be set via the CommandCenter display.

Operator presses brake pedal to stop the tractor

Operator presses brake pedal to stop the tractor

AutoClutch sensitivity change on CommandCenter display

AutoClutch sensitivity change on CommandCenter display

Benefits

Torque

Overview

The AutoPowr/IVT transmission is a combination of mechanical and hydraulic components that can provide low speed with extremely high levels of torque:

Creeper mode

Creeper mode is a standard feature on the AutoPowr/IVT transmission. Down to 50 m/h (164 ft/h), the creeper mode is activated when the selected speed is below 2.1 km/h (1.3 mph) in set position 1.

When the tractor moves below 600 m/h (1968 ft/h), the engine speed is independent of travel speed. This allows the operator to choose the engine speed that best fits the task (rated speed for hydraulic or PTO usage, or low idle for fuel-saving operation). No additional power is needed.

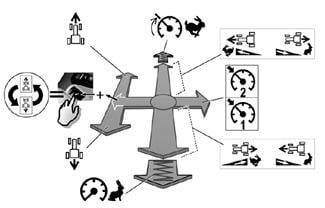

The optional CommandPRO joystick combines a unique driving strategy with reconfigurable controls.

CommandARM© controls with CommandPRO

CommandARM© controls with CommandPRO

|

1 ™ travel set speed buttons 1 and 2 |

|

4 ™ reconfigurable buttons and rocker switches (buttons 10 and 11, rocker switches C and D) |

Benefits

| Code | Description |

| 2089 | Standard Cab with CommandPRO |

| 2091 | Premium Cab with CommandPRO |

| 2092 | Premium Cab with CommandPRO and cab suspension |

| Rocker D: selective control valve (SCV) II (if equipped) | Button 10: engine set speed 1 |

| Rocker C: SCV I (if equipped) | Button 11: engine set speed 2 |

| Rocker B: front hitch (if equipped) | Button 12: AutoTrac© resume (if equipped) |

| Rocker A: rear hitch (if equipped) |

NOTE: For information about reconfigurability, please see operator's station functional area.

The unique driving strategy is designed to deliver highest performance in combination with operator comfort making the daily work much easier and efficient.

Driving strategy

Driving strategy

| Forward movement | Reverse movement | |

| 1 | Accelerate | Decelerate |

| 2 | Top set speed | Zero speed |

| 3 | Decelerate | Accelerate |

| 4 | Zero speed | Accelerate |

| 5 | Activate set speed | |

| 6 | Select direction | |

| 7 | Inching speed | |

| 8 | Inching speed | |

CommandPRO joystick driving functions

CommandPRO joystick driving functions

The change between using the foot pedal or the joystick can happen while driving for ease of use and comfort. The simple rule is: the higher speed command is superior. When changing from the pedal to the joystick, there is a short overlap where the joystick takes over the command from the pedal before the pedal is released. Similar, when changing from joystick control to the foot pedal, the driver needs to push the foot pedal to the point of speed where the joystick is before it can take over.

The inching control of the CommandPRO joystick simplifies the attachment of implements. Once the joystick is pushed into the inching range, the tractor moves very slowly in the selected direction. Speed is dependent on the joystick position and can be speed between 0 and 2 km/h (0 and 1.2 mph). Maximum speed of the inching range can be set to 5 km/h (3.1 mph) with the travel speed adjustment wheel.

Unlike the main range, releasing the joystick means the speed is reduced until the vehicle stops completely. This allows the operator to fully focus on the implement and quickly stop if required.

Inching control on CommandPRO joystick

Inching control on CommandPRO joystick

The travel set speed buttons on the CommandPRO joystick allow the operator to set two set speeds. The operator has to preselect the desired set speed by pushing the travel set speed button 1 or 2 and once the joystick is pushed to the right, the set speed is activated and the travel speed will be adjusted until the set speed is achieved. Additionally, the operator can set a maximum travel speed through the travel speed adjustment wheel or in the CommandCenter© display.

There are different ways to set or adjust the set speeds:

The operator can also set a dedicated set speed when changing the travel direction. For example, the tractor is driving forward at 10 km/h (6.2 mph) and for reversing the reverse shuttle shift speed is set to 5 km/h (3.1 mph). This means when the shuttle shift takes place, the tractor will accelerate to 5 km/h (3.1 mph) in reverse direction. This function can be turned on/off and set to the dedicated speed in the CommandCenter display.

Set speeds and shuttle shift speeds in the CommandCenter

Set speeds and shuttle shift speeds in the CommandCenter

The three settings for acceleration and deceleration with the CommandPRO joystick can be changed by pressing acceleration response button. Three light-emitting diodes (LEDs) next to the set button indicate the currently activated setting.

Three settings for acceleration and deceleration

Three settings for acceleration and deceleration

The settings influence the following:

To ensure comfortable and reliable deceleration of the tractor with both the foot pedal and the CommandPRO joystick the tractor is equipped with unique technology. The engine overspeed protection ensures that both transmission and engine are not overloaded when decelerating. Additionally, the anti-jackknife technology compares wheel speed of front and rear wheels when decelerating through the joystick, as this means that the front brakes are not applied but only through the rear axle. If the front wheels are moving quicker, the transmission automatically adjusts to ensure the same wheel speed and avoid the jackknife situation.

The park lock is disengaged automatically when commanding any direction of travel. Additionally, it engages automatically when the driver leaves the driver seat while the tractor is stationary. If the tractor is equipped with a trailer brake, this logic also applies for the trailer brake.

The buttons for the park lock and neutral position are next to the CommandPRO joystick on the CommandARM controls. There is no park lock or neutral position available in the left-hand reverser.

CommandPRO joystick with neutral and park position

CommandPRO joystick with neutral and park position

ComfortView cabs feature a modern, automotive-style instrument panel as base equipment. The instrument pod has two large analog dials for engine and tractor speed, as well as two smaller dials that display fuel level, diesel exhaust fluid (DEF) level, and coolant temperature. The steering column and dash are adjustable to suit the operator's needs. The column tilts toward the operator and a lever on the left-hand side allows for the column to telescope out to the desired level.

A dimming mode automatically reduces the brightness of the instrument illumination when the tractor lights are used.

Cab and controls of 6R Tractor

Cab and controls of 6R Tractor

Steering column on 6R Tractor

Steering column on 6R Tractor

Overview

The instrumentation panel has a row of information and warning lights across the bottom to monitor all important tractor functions. A three-stage warning system first gives information, then gives warnings, and finally, gives a stop alarm to prevent damage from occurring in the event of a component malfunction. An integrated power take-off (PTO) over-speed warning is incorporated into the diagnostics to ensure proper operation.

Instrumentation control panel

Instrumentation control panel

Dash instrument panel controls include:

| Left side | Right side |

| Left-hand reverser | Two-speed and optional intermittent wiper |

| High-/low-beam switch | Key start/stop |

| Hazard switch | Road/work lights on/off |

| Self-cancelling turn signals/horn |

Overhead storage compartment

Overhead storage compartment

CommandARM© console storage compartment

CommandARM© console storage compartment

Overview

The 6R Series features a redesigned CommandARM console with all key vehicle functions in one place. The updated CommandARM layout is only available with Infinitely Variable Transmission (IVT©) and DirectDrive transmissions. The base 21.3-cm (8.4-in.) 4200 CommandCenter© Display or optional 25.4-cm (10-in.) (4600 CommandCenter Display is fully integrated onto the CommandARM and offers fast adjustment of additional tractor functions.

The CommandARM design allows for 37.5 degrees of total seat swivel and adjustable positioning matching the operator’s preference. (30 degrees right and 7.5 degrees left).

Hydraulic and hitch controls utilize fingertip paddle pots for raise/lower and extend/retract functions. The CommandARM offers up to a maximum of six electronic selective control valves (E-SCVs) (without electronic joystick). The optional electrical joystick replaces fingertip paddle pots for control of selective control vales (SCVs) and allows for programmable hydraulic functionality according to operator preference. A maximum of five E-SCVs can be ordered with the electronic joystick. For tractors with an IVT transmission, the CommandPRO© joystick is available. Its 11 reconfigurable buttons enable the operator to have all necessary controls accessible without hand movements (for details, click here).

Controls for radio, lights, rotary beacon, and hazard flashers are located to the center right on the CommandARM along with PTO for front (if equipped) and rear PTO. Additionally, located on the right side of the CommandARM is an encoder wheel which allows for finite positioning of the rear 3-point hitch. There are three buttons near the encoder for set lock and return to height. Adjustment knobs for the 3-point hitch are located under the cover for the CommandARM storage compartment and allow for adjustment of the rate of drop, hitch height limit, and depth control.

The transmission control and throttle are placed on the left side of the CommandARM closest to the operator for convenient setting and adjustment. The throttle design incorporates buttons which control engine cruise speed, pedal lock/cruise control, and transmission Eco settings (for more information, refer to the AutoPowr© or DirectDrive transmissions pages).

Located just to the right of the throttle is the auto-steer activation button and four sequence controls for iTEC© functions. Behind the iTEC sequence controls are buttons which control the activation and deactivation of mechanical front-wheel drive (MFWD) and differential lock.

Differential lock can also be activated by foot switch on the cab floor. A feature in the 6R Series Tractor is auto steering angle dependent differential lock button.

Operators can easily identify controls by icons located near levers, and each functional area is color coded.

Functions:

ComfortView cab with CommandARM console

ComfortView cab with CommandARM console

Close up of controls on the CommandARM

Close up of controls on the CommandARM

Optional integrated crossgate joystick

Optional integrated crossgate joystick

CommandPRO controls (IVT only)

CommandPRO controls (IVT only)

Hand throttle feature

Hand throttle feature

3-point hitch control layout

3-point hitch control layout

Integrated differential lock features

Integrated differential lock features

Benefits

Overview

The right-hand control console is angled for operator comfort and ease of operation. The design of the right-hand console is controlled by the type of SCVs chosen.

Mechanically actuated valves are controlled by traditional levers, while electronically actuated valves are controlled by fingertip paddle pots. Controls for the ComfortView cab are grouped by function on the right-hand console.

The modular console panel provides individual access to hand throttle, transmission controls, MFWD switch (if equipped), hitch command console, load/draft control, SCV, and PTO controls.

The console is also the location of the CommandCenter display. The CommandCenter allows the operator to customize important tractor functions.

This option requires a PowrQuad© or AutoQuad© transmission.

ComfortView cab right-hand console (AutoQuad transmission is shown)

ComfortView cab right-hand console (AutoQuad transmission is shown)

Hitch control module on right-hand console

Hitch control module on right-hand console

M-SCV controls on the right-hand console

M-SCV controls on the right-hand console

E-SCV controls on the right-hand console

E-SCV controls on the right-hand console

Benefits

Overview

The 6R Tractors have seven cab packages designed to match producers' operations. There are three levels of comfort - economy, standard, and premium. There are two control configurations available: a right-hand console for the PowrQuad PLUS or AutoQuad PLUS transmissions and the CommandARM console for the IVT and DirectDrive transmissions. There is an option for hydraulic cab suspension for the premium package. Below is a chart showing the available packages and what is included in each package.

Benefits

Details

Base features in all cab packages:

| Cab packages | Economy right-hand console |

Standard right-hand console |

Standard CommandARM |

Premium right-hand console | Premium CommandARM |

Premium right-hand console and cab suspension |

Premium CommandARM and cab suspension |

Standard cab with CommandPRO | Premium cab with CommandPRO | Premium cab with CommandPRO and cab suspension |

| Package code | 2050 | 2057 | 2060 | 2063 | 2064 | 2067 | 2068 | 2089 | 2091 | 2092 |

| Two panorama doors (left-hand and right-hand sides) | X | X | X | X | X | X | X | X | X | X |

| Standard seat (Grammer®) | X | X | X | X | --- | --- | --- | X | --- | --- |

| Premium seat (Grammer DDS) | --- | --- | --- | --- | X | X | X | --- | X | X |

| Instructional seat | X | X | X | X | X | X | X | X | X | X |

| Bottle holder | X | X | X | X | X | X | X | X | X | X |

| Mirrors - right hand and left hand - manually adjustable and telescopic | X | X | X | --- | --- | --- | --- | X | --- | --- |

| Wide-angle mirrors - right hand and left hand - electrically adjustable | --- | --- | --- | X | X | X | X | --- | X | X |

| Front sun visor | X | X | X | --- | --- | --- | --- | X | X | X |

| Front and rear roller blind | --- | --- | --- | X | X | X | X | --- | --- | --- |

| Rear wiper and washer | --- | X | X | X | X | X | X | X | X | X |

| Manual temperature controls | X | X | X | --- | --- | --- | --- | X | X | X |

| Automatic temperature controls | --- | --- | --- | X | X | X | X | --- | X | X |

| Hydraulic cab suspension | --- | --- | --- | --- | --- | X | X | --- | --- | X |

| CommandPro | --- | --- | --- | --- | --- | --- | --- | X | X | X |

| Leather comfort package | --- | --- | --- | --- | --- | X | X | --- | X | X |

*6155RH right-hand console only

| Cab packages | Standard CommandARM | Premium CommandARM | Premium CommandARM and cab suspension | Standard cab with CommandPRO | Premium cab with CommandPRO | Premium cab with CommandPRO and cab suspension |

| Package code | 2060 | 2064 | 2068 | 2089 | 2091 | 2092 |

| Two panorama doors (left-hand and right-hand sides) | X | X | X | X | X | X |

| Standard seat (Grammer) | X | --- | --- | X | --- | --- |

| Premium seat (Grammer DDS) | --- | X | X | --- | X | X |

| Instructional seat | X | X | X | X | X | X |

| Bottle holder | X | X | X | X | X | X |

| Mirrors - right hand and left hand - manually adjustable and telescopic | X | --- | --- | X | --- | --- |

| Wide-angle mirrors - right hand and left hand - electrically adjustable | --- | X | X | --- | X | X |

| Front sun visor | X | --- | --- | X | X | X |

| Front and rear roller blind | --- | X | X | --- | --- | --- |

| Rear wiper and washer | X | X | X | X | X | X |

| Manual temperature controls | X | --- | --- | X | X | X |

| Automatic temperature controls | --- | X | X | --- | X | X |

| Hydraulic cab suspension | --- | --- | X | --- | --- | X |

| CommandPRO | --- | --- | --- | X | X | X |

| Leather comfort package | --- | X | X | --- | X | X |

Grammer is a trademark of Grammer AG Aktiengesellschaft.

A single manual action; system manages the rest

A single manual action; system manages the rest

TBA awards

TBA awards

The optional Tractor-Baler Automation (TBA) makes baling easy. This exclusive system manages most of the baling process and gives the producer the following advantages:

When used with a John Deere ISOBUS tractor, electric selective control valve (E-SCV), and (IVT©) transmission, the system will be able to:

The only action remaining is to forward reverser and manage the steering.

If the John Deere tractor is not equipped with IVT but has E-SCV and ISOBUS, opening and closing can be automated.