Faster spray and transport speed allow operators to get to the field sooner

Field speeds increased to 40 km/h (25 mph)

Field speeds increased to 40 km/h (25 mph) Road speeds increased to 56 km/h (35 mph)

Road speeds increased to 56 km/h (35 mph)Efficiency and productivity are key drivers to any successful application operation. To meet this need, the R4038 and R4045 have increased spray and transport speeds allowing operators to get jobs done faster and move onto the next field sooner. Operators can now travel 25 percent faster across the field, allowing them to spray more acres per day. Transport speed has also been increased by 16.5 percent, which gets operators to the next field quicker. This translates into a 40 km/h (25 mph) spray speed and 56 km/h (35 mph) road transport speed, boosting overall productivity throughout the day.

NOTE: If product is in the solution tank or dry bin, the level sensor inside of the tank or bin will limit machine transport speed to 48.3 km/h (30 mph).

36-m (120-ft) boom with swing-link suspension eliminates additional passes through the field

Make fewer passes through the field and reduce compaction, as well as time spent spraying, with the optional 36 m (120 ft) boom.

All 27-m (90-ft), 30-m (100-ft), and 36-m (120-ft) booms are more stable thanks to the swing link suspension, which helps translate rough areas in the field into horizontal (side-to-side) movement of the boom rather than lateral (up and down) movement. This additional stability means increased productivity as the boom now has the ability to more accurately maintain spray height above the crop, delivering a precise spray pattern. The swing link suspension also translates into uptime as the additional stability means less crop damage, resulting in less mechanical boom damage.

Finally, the enhanced design allows the boom to unfold and fold faster, getting the operators into the field more quickly, and the flat fold design delivers superior transport visibility.

Solution Command System (SCS) allows for automation at the fill station

Solution Command offer push button loading

Solution Command offer push button loading 12-button keypad and micro-display

12-button keypad and micro-display4 Series Sprayers are available with the SCS and have been completely redesigned to allow quick and easy operation at the load station for all operator skill levels. The optional system allows complete automation at the load station with a 12-button keypad. The features include the following:

- Fill station light on/off

- Pump on/off

- Agitation

- Pump speed increase

- Pump speed decrease

- Eductor on/off

- Master on/off

- Automated rinse cycle

- Visual nozzle check

- Pull-on fill

- Push-on fill

- Target fill

The system also features a micro-display, providing real-time feedback on the system operations, as well as ability to select a rinse method and the ability to monitor progress during the automated rinse function. Overall, the enhanced Solution Command System increases operational performance by increasing ease of use through automation at the load station.

Plumbing efficiencies lead to increased application rates, additional versatility as well as faster loading times

The John Deere 4 Series Sprayers have been designed to address the trend toward increased application rates and the desire for improved loading efficiencies. In fact, the R4030, R4038, and R4044 offer the most efficient liquid fertilizer application systems and the fastest loading times that John Deere has ever offered on this size of sprayers to date.

The solution system has been redesigned from the ground up to streamline plumbing for maximum efficiency and flow rate. The standard-flow system (standard solution pump and single flow meter) delivers 30 percent higher flow rates than previous models, up to 643.5 L/min (170 gpm) of output. The optional high-flow system offered on the R4038 and R4044 comes complete with a high-flow pump and dual-flow meters and delivers up to a 60 percent increase from previous models, equating to approximately 851.7 L/min (225 gpm) of output.

Additionally, load times using the on-board solution pump are up to 30 percent faster. This means operators can get back into the field sooner and spend less time filling. These improvements to the plumbing system all link to enhanced versatility and productivity for operators as they strive to increase the effectiveness of their application passes and drive towards increased yields year over year.

ExactApply™ nozzle control increases precision application to maximize yield potential

John Deere ExactApply nozzle control ExactApply nozzle control

ExactApply nozzle control

With ExactApply nozzle control, sprayer operators will see an increase in productivity and spray speed ranges, will be able to better manage drift, and will have improved spray quality and precision.

ExactApply offers operators:

- Individual nozzle control

- Pulse-width modulation of 15 and 30 Hz

- Wider speed range while maintaining target rate and pressure

- Turn compensation

- Light-emitting diode (LED) lighting

- Nozzle switching (automatic/manual)

- Ability to apply liquid nitrogen at wider range of speeds

- Air induction nozzle compatibility

- Programmable rates by nozzle/selection (for example, a higher rate behind rear tires)

- Key fob for nozzle diagnostics

- Solenoid fault detection

NOTE: ExactApply will be available as a factory-installed option on model year 2018 R4030, R4038, and R4045 Sprayers with stainless-steel plumbing and 38.1- or 50.8-cm (15- or 20-in.) nozzle spacing.

Smooth, stable ride enables operator comfort and better maneuverability

Machine performance and operator comfort are requirements during long days of operation. The field-proven dual strut independent wheel air-ride suspension reduces overall machine maintenance. This suspension also provides a best-in-class ride, which is expected from John Deere Sprayers, even in the roughest fields.

Additionally, approximately 9 percent of the machine weight has been transferred to the front axle of the R4030, R4038, and R4044, which leads to improved balance and further increases machine maneuverability. These features lead to less operator adjustment in the field and on the road. At the end of the day, a smooth, stable ride allows the operator the ability to travel faster across the field and cover more acres, leading to increased productivity.

CommandView™ III cab offers unsurpassed amenities

4 Series Sprayer operator station

4 Series Sprayer operator stationWhen operators first enter the Command View III cab, they will notice that significant changes have been made. Key sprayer controls are more easily accessible to the operator on the redesigned CommandARM™ control panel and the multifunction handle has a more ergonomic fit and feel.

The multifunction handle has six reconfigurable buttons, a scroll to select speed range, and allows operators to better manage their headlands with the Headland Management System (HMS™) button. To finish out the upgrades, the GreenStar™ display has been upgraded to a faster, more user-friendly 4600 CommandCenter™ display, which allows operators to efficiently capture, manage, and transfer data.

Comfort continues to be enhanced by the ComfortCommand™ seat, which offers both fore-aft and lateral attenuation along with 15 degrees of right-hand seat swivel on all cab options. For first-class comfort, the premium cab offers a heated/ventilated leather seat and light-emitting diode (LED) cab lights.

The 4 Series Sprayers are JDLink™ telematics system capable, which enable features such as John Deere Wireless Data Transfer (WDT), Service ADVISOR™ Remote diagnostics, and Remote Display Access (RDA). These integrated solutions enable additional uptime and reduce cost of operation. All of the CommandView III cab features allow operators to run longer hours, increasing the ability to get more acres sprayed in a day.

Direct injection allows operators to manage their chemical risks

Field-installed 511-L (135-gal.) direct-injection system

Field-installed 511-L (135-gal.) direct-injection system Field-installed 889-L (235-gal.) direct-injection system

Field-installed 889-L (235-gal.) direct-injection systemAs solution tank mixes become more complex, operators need a better way to manage the products they are mixing in helping to reduce the risk of chemical residue. The integrated direct-injection system provides an additional carrying capacity for raw chemicals and allows injection of single, dual, or triple products directly into the boom depending on installed configuration.

| Machine | Direct injection

carrying capacity | Injection capability |

R4030/R4038

model year 2015 and older

(serial number 10,999 and lower) | 511 L (135 gal.) | Inject up to two chemicals

(one high volume, one low volume) |

R4030/R4038

model year 2016 and newer

(serial number 11,000 and higher) | 889 L (235 gal.) | Inject up to three chemicals

(two high volume, one low volume) |

| R4045 | 889 L (235 gal.) | Inject up to three chemicals

(two high volume, one low volume) |

NOTE: Low-volume tanks and pumps must be configured with at least one high-volume tank and pump. High-volume tank and pump can be configured by itself.

Direct injection helps provide quicker changeovers and faster cleanouts while also helping to minimize the risk of using multiple chemicals. This is accomplished by allowing operators the ability to isolate higher-residual-risk chemicals in the injection system while mixing lower-risk chemicals in the solution tank.

The minimum and maximum application rates for each pump are as follows:

| Direct injection pump system | High-rate pump | Low-rate pump |

Application rate range

(minimum to maximum) | 148-5900 mL/min (5-200 oz/min) | 29.6-1183 mL/min (1-40 oz/min) |

| Agitation capability | Not available – suspension products not recommended | Not available – suspension products not recommended |

NOTE: See Operator’s Manual for additional details based on boom size and speed range, and refer to Tools/Direct Inject Calculator within the ApplyPlus™ mobile app (download via Apple® App Store® or Google Play™ store).

Apple and App Store are trademarks of Apple Inc. Google Play is a trademark of Google LLC.

Monitor sprayer performance in the cab

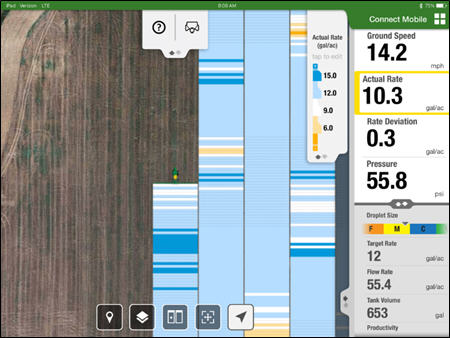

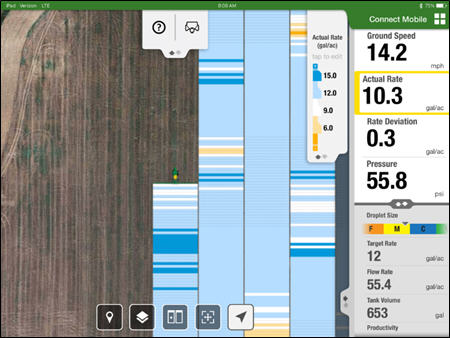

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performanceConnect Mobile overview

John Deere Connect Mobile is a solution that utilizes an Apple® iPad® tablet in the cab that provides the operator a better understanding of the sprayer’s performance. Connect Mobile documents and displays several sprayer performance attributes, helping the operator monitor and more easily detect problems that can occur while spraying. Connect Mobile also has a common user interface that makes it easy to use between different pieces of John Deere equipment. Once the job is done, the iPad with the spraying data can be utilized to perform basic crop scouting activities in the field.

Spraying attributes

Monitor key performance indicators in map layers and dashboard tiles such as:

- Actual rate

- Rate deviation

- Pressure

- Ground speed

- Droplet size

- Target rate

- Flow rate

- Tank volume

- Productivity

- Fuel rate

In base equipment

Connect Mobile hardware is factory installed on all model year 2017 and newer R4030, R4038, and R4045 Sprayers, making it easy to get started with Connect Mobile.

Learn more about Connect Mobile in the Field and Crop Solutions section within the Precision Ag Technology product line and how it can improve the quality of a spraying job.

iPad and Apple are trademarks of Apple Inc.

Dry spinner spreader compatibility increases versatility by allowing the conversion of a machine with a wet solution system into a dry nutrient applicator with a 5.6-m3 (200-cu ft) carrying capacity

At the end of the spraying season operators can keep their sprayers working for them by converting them to dry nutrient applicators with the addition of the New Leader® DN456 Dry Spinner Spreader. This conversion can be completed in as little as 4 hours and involves the removal of the wet solution skid and the installation of the dry spinner spreader.

The DN456 features a carrying capacity of up 5.6 m3 (200 cu ft) of dry fertilizer and is capable of holding 6.6 tons of fertilizer (not approved for ag lime) with variable rate applications from 34 kg/ha (75 lb/acre) up to 3 ton/acre. The 1.83-m (72-in.) spinner heights allow spread width up to 32 m (105 ft) as it propels material across the pass. This equates to a consistent spread pattern across the field and decreased cost of operation for the 4 Series Sprayers.

The DN456 can be ordered with either 304 stainless-steel or 409 painted spreader material, single or dual product bin configuration, with a #4 belt over chain conveyor.

New Leader is a registered trademark of Highway Equipment Company.

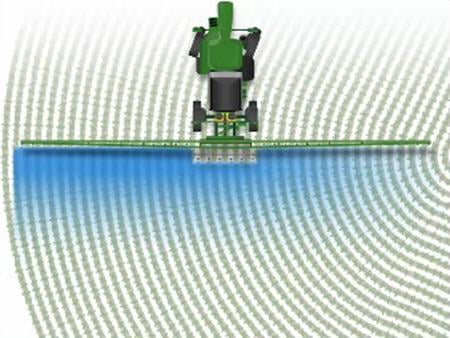

Boom swing-link suspension eliminates additional passes through the field

Make fewer passes through the field and reduce compaction, as well as time spent spraying, with John Deere booms.

All John Deere booms are more stable due to the swing link suspension, which helps translate rough areas in the field into horizontal (side-to-side) movement of the boom rather than lateral (up and down) movement. This additional stability means increased productivity as the boom now has the ability to more accurately maintain spray height above the crop, delivering a precise spray pattern. The swing link suspension also translates into uptime as the additional stability means less crop damage, resulting in less mechanical boom damage.

The enhanced design allows the boom to unfold and fold faster, getting the operators into the field quicker, and the flat fold design delivers superior transport visibility.

ExactApply™ nozzle control delivers precise application with up to 20 acres per hour of added productivity

Turn compensation mode

Turn compensation mode

Individual nozzle control mode

Individual nozzle control mode

John Deere’s intelligent nozzle control system ExactApply helps producers better manage drift and deliver a precise application. By maintaining target rate and pressure over a wider speed range, ExactApply can improve productivity up to 20 acres per hour*.

*NOTE: Assumes a 3.2-km/h (2-mph) average operating speed increase.

ExactApply is offered as a factory-installed option as well as a performance upgrade kit that can be added to existing 4 Series Sprayer models.

How it works

The ExactApply system features multiple modes of operation including pulse-width modulation (PWM) and individual nozzle control:

- 15-Hz PWM pulses one solenoid to achieve a consistent droplet size and maintain spray pressure throughout a wider range of speeds and application rates.

- 30-Hz PWM (combined mode) pulses both solenoids in the ExactApply nozzle body at 15 Hz, providing superior coverage. Combined mode allows ExactApply to have a 25 percent increased flow over current competitive systems in the market.

- AutoSelect A/B automatically switches between two nozzles to maintain the desired spray pressure range while spraying conventionally.

- Turn compensation varies the rate across the boom, ensuring the desired application rate. The rate decreases on the inside of the turn to not subject crop to chemical burn, while the rate on the outside of boom increases, ensuring the crop receives the desired application rate.

- Individual nozzle control minimizes overlap by controlling product application through individual nozzles. This reduces chemical cost and ensures the product is placed where it is needed most. In comparison, traditional nozzle control functions in 11 sections, meaning section widths vary from 2.4 to 3.35 m (8 to 11 ft), depending upon boom width.

Increase versatility with a DN456 Dry Spinner Spreader

Keep your machines working for you by converting them to dry nutrient applicators with the addition of a New Leader® DN456 Dry Spinner Spreader. This conversion can be completed in as little as 4 hours and involves the removal of the wet solution skid and the installation of the dry spinner spreader.

The DN456 features a carrying capacity of up 5.6 m3 (200 cu ft) or 6.6 tons of dry fertilizer (not approved for ag lime) and is capable of variable rate applications from 34 kg/ha (75 lb/acre) up to 3 ton/acre. The 1.83-m (72-in.) spinner heights allow spread width up to 32 m (105 ft) as it propels material across the pass. The New Leader G4 spinner technology provides a consistent spread pattern across the field for uniform pass to pass application.

The DN456 can be ordered with either 304 stainless-steel or 409 painted spreader material in single or dual product bin configurations with a #4 belt over chain conveyor.

New Leader is a registered trademark of Highway Equipment Company.

Operator controls within easy reach in CommandView™ III cab with integrated GreenStar™ 4600 CommandCenter™ display

4 Series Sprayer operator station

4 Series Sprayer operator station

When operators first enter the Command View III cab, they will notice that significant changes have been made. Key sprayer controls are more easily accessible to the operator on the redesigned CommandARM© control panel and the multifunction handle has a more ergonomic fit and feel.

The multifunction handle has six reconfigurable buttons, a scroll to select speed range, and allows operators to better manage their headlands with the Headland Management System (HMS©) button. To finish out the upgrades, the GreenStar© display has been upgraded to a faster, more user-friendly 4600 CommandCenter© display, which allows operators to efficiently capture, manage, and transfer data.

Comfort continues to be enhanced by the ComfortCommand© seat, which offers both fore-aft and lateral attenuation along with 15 degrees of right-hand seat swivel on all cab options. For first-class comfort, the premium cab offers a heated/ventilated leather seat and light-emitting diode (LED) cab lights.

The 4 Series Sprayers are JDLink© telematics system capable, which enable features such as John Deere Wireless Data Transfer (WDT), Service ADVISOR© Remote diagnostics, and Remote Display Access (RDA). These integrated solutions enable additional uptime and reduce cost of operation. All of the CommandView III cab features allow operators to run longer hours, increasing the ability to get more acres sprayed in a day.

Steel and carbon-fiber booms feature swing-link suspension for optimum stability

Make fewer passes through the field and reduce compaction, as well as time spent spraying, with John Deere booms.

All John Deere booms are more stable due to the swing link suspension, which helps translate rough areas in the field into horizontal (side-to-side) movement of the boom rather than lateral (up and down) movement. This additional stability means increased productivity as the boom now has the ability to more accurately maintain spray height above the crop, delivering a precise spray pattern. The swing link suspension also translates into uptime as the additional stability means less crop damage, resulting in less mechanical boom damage.

The enhanced design allows the boom to unfold and fold faster, getting the operators into the field quicker, and the flat fold design delivers superior transport visibility.

Automate tasks from filling station with Solution Command System

Solution Command offer push button loading

Solution Command offer push button loading

12-button keypad and micro-display

12-button keypad and micro-display

4 Series Sprayers are available with the SCS and have been completely redesigned to allow quick and easy operation at the load station for all operator skill levels. The optional system allows complete automation at the load station with a 12-button keypad. The features include the following:

- Fill station light on/off

- Pump on/off

- Agitation

- Pump speed increase

- Pump speed decrease

- Eductor on/off

- Master on/off

- Automated rinse cycle

- Visual nozzle check

- Pull-on fill

- Push-on fill

- Target fill

The system also features a micro-display, providing real-time feedback on the system operations, as well as ability to select a rinse method and the ability to monitor progress during the automated rinse function. Overall, the enhanced Solution Command System increases operational performance by increasing ease of use through automation at the load station.

Direct injection system expands carrying capacity for raw chemicals

Field-installed 511-L (135-gal.) direct-injection system

Field-installed 511-L (135-gal.) direct-injection system

Field-installed 889-L (235-gal.) direct-injection system

Field-installed 889-L (235-gal.) direct-injection system

As solution tank mixes become more complex, operators need a better way to manage the products they are mixing in helping to reduce the risk of chemical residue. The integrated direct-injection system provides an additional carrying capacity for raw chemicals and allows injection of single, dual, or triple products directly into the boom depending on installed configuration.

| Machine |

Direct injection

carrying capacity |

Injection capability |

R4030/R4038

model year 2015 and older

(serial number 10,999 and lower) |

511 L (135 gal.) |

Inject up to two chemicals

(one high volume, one low volume) |

R4030/R4038

model year 2016 and newer

(serial number 11,000 and higher) |

889 L (235 gal.) |

Inject up to three chemicals

(two high volume, one low volume) |

| R4045 |

889 L (235 gal.) |

Inject up to three chemicals

(two high volume, one low volume) |

NOTE: Low-volume tanks and pumps must be configured with at least one high-volume tank and pump. High-volume tank and pump can be configured by itself.

Direct injection helps provide quicker changeovers and faster cleanouts while also helping to minimize the risk of using multiple chemicals. This is accomplished by allowing operators the ability to isolate higher-residual-risk chemicals in the injection system while mixing lower-risk chemicals in the solution tank.

The minimum and maximum application rates for each pump are as follows:

| Direct injection pump system |

High-rate pump |

Low-rate pump |

Application rate range

(minimum to maximum) |

148-5900 mL/min (5-200 oz/min) |

29.6-1183 mL/min (1-40 oz/min) |

| Agitation capability |

Not available ™ suspension products not recommended |

Not available ™ suspension products not recommended |

NOTE: See Operator’s Manual for additional details based on boom size and speed range, and refer to Tools/Direct Inject Calculator within the ApplyPlus© mobile app (download via Apple® App Store® or Google Play© store).

Apple and App Store are trademarks of Apple Inc. Google Play is a trademark of Google LLC.

Precision Ag Technology enables you to monitor performance and maximize productivity

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

Connect Mobile overview

John Deere Connect Mobile is a solution that utilizes an Apple® iPad® tablet in the cab that provides the operator a better understanding of the sprayer’s performance. Connect Mobile documents and displays several sprayer performance attributes, helping the operator monitor and more easily detect problems that can occur while spraying. Connect Mobile also has a common user interface that makes it easy to use between different pieces of John Deere equipment. Once the job is done, the iPad with the spraying data can be utilized to perform basic crop scouting activities in the field.

Spraying attributes

Monitor key performance indicators in map layers and dashboard tiles such as:

- Actual rate

- Rate deviation

- Pressure

- Ground speed

- Droplet size

- Target rate

- Flow rate

- Tank volume

- Productivity

- Fuel rate

In base equipment

Connect Mobile hardware is factory installed on all model year 2017 and newer R4030, R4038, R4044, R4045, and R4060 Sprayers, making it easy to get started with Connect Mobile.

Learn more about Connect Mobile in the Field and Crop Solutions section within the Precision Ag Technology product line and how it can improve the quality of a spraying job.

iPad and Apple are trademarks of Apple Inc.

CommandDrive™ powertrain delivers improved efficiency with Auto Mode

Experience fuel saving and noise reduction with CommandDrive

Experience fuel saving and noise reduction with CommandDrive

Spray more acres per day at a lower cost of operation with the CommandDrive powertrain. You will see an improved system response to maintain consistent application and transport speeds in challenging conditions, while reducing overall fuel consumption and cab noise.

The CommandDrive powertrain comes in base on all R4060, R4045, R4044, R4038, and R4030 Sprayers. This powertrain has the following features:

- Auto Mode dynamically commands engine speed depending on load requirements

- Reduce engine speed and save up to 20 percent on fuel consumption

- 3- to 5-decibel reduction in noise for long hours in the cab

- Single pump flow instead of two

- Improved traction control

Deliver accurate rate control with integrated SpreadStar™ dry rate control system

SpreadStar dry rate control on Gen 4 4600 CommandCenter© display

SpreadStar dry rate control on Gen 4 4600 CommandCenter© display

The SpreadStar dry rate control system is a standard feature that is integrated into the design of the self-propelled spreader chassis (not a third-party ISO control add-on) and delivers accurate and consistent on-target rate control. All dry spreading and vehicle functions are displayed on the Gen 4 4600 CommandCenter display for easy operation and setup. In addition to these functions, all precision technology can be used on the same display for complete integration and ease of operation. The engine, chassis, dry spreader system, and precision controllers provide central communication through the display for many vehicle and dry system functions that are simple and easy to use.

- Provides superior rate control, response times, and ease of use

- Rate control locks on to the desired application rate much more quickly and maintains it better than third-party controllers

- Easy to understand and simple to set up the key values you must enter to execute the spreading job

- No cross reference to nodes or a task controller like other third-party systems

- High-speed hydraulic pulse-width modulated control valve varies conveyor shaft speed to produce only the required product flow with easy-to-follow feed rate calibration procedures

Engine, transmission, and hydraulic drive pump work together to optimize efficiency of the entire system, providing fuel savings and optimizing power to the ground and delivery of product to the spinners

Deliver accurate rate control with integrated SprayStar™ spray rate control system

SprayStar spray rate control on Gen 4 4600 CommandCenter© display

SprayStar spray rate control on Gen 4 4600 CommandCenter© display

The SprayStar spray rate control system is a standard feature that is integrated into the design of the self-propelled sprayer system (not a third-party ISO control add-on) and delivers accurate and consistent on-target rate control. All spraying and vehicle functions are displayed on the Gen 4 4600 CommandCenter display for easy operation and setup. In addition to these functions, all precision technology can be used on the same display for complete integration and ease of operation. The engine, chassis, solution system, and precision controllers provide central communication through the display for many vehicle and solution system functions that are simple and easy to use.

- Provides superior rate control, response times, and ease of use

- Rate control locks on to the desired application rate much more quickly and maintains it better than third-party controllers

- Easy to understand and simple to set up the key values you must enter to execute the spraying job

- No cross reference to nodes or task controller like other third-party systems

- High-speed hydraulic pulse-width modulated control valve varies solution pump speed to produce only the required solution flow in coordination with the flow meter and pressure sensor rather than a valve to restrict flow

Engine, transmission, and hydraulic drive pump work together to optimize efficiency of the entire system, providing fuel savings and optimizing power to the ground and delivery of product through the solution system to the nozzles

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

Connected Support technology

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink© telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

|

Key Specs

|

| Engine |

Peak rated power

231 kW

310 hp

|

| Solution system - Capacity |

3800 L

1000 gal. |

|

Solution system

|

| Rinse tank capacity |

454.2 L

120 gal. |

|

Key Specs

|

| Boom length options/Material |

27.4, 30.4, 36.5, or 40 m

90, 100, 120, or 132 ft

Boom Material: Steel or carbon fiber |

|

Drivetrain

|

| Spray speed range |

0 to 40.2 km/h

0 to 25 mph |

| Transport speed, maximum |

56.3 km/h

35 mph

Europe only - 40 km/h

24.9 mph |

|

Chassis

|

| Suspension |

Dual-strut independent wheel air-ride suspension |

| Crop clearance with standard tires |

152 cm

60 in. |

|

Key Specs

|

| Total weight with widest boom |

13,805 kg

30,435 lb |

|

Engine

|

| Peak rated power |

231 kW

310 hp |

| Emissions |

Final Tier 4 |

| Number of cylinders |

6 |

| Displacement |

9 L

549 cu in. |

| Alternator |

200 amp |

| Fuel tank capacity |

605.7 L

155 gal. |

| Diesel exhaust fluid (DEF) tank capacity |

29.5 L

7.8 gal. |

|

Solution system

|

| Capacity |

3800 L

1000 gal. |

| Tank material |

Stainless steel |

| Quick fill size |

7.6 cm

3 in. |

| Automatic section control |

John Deere Section Control (optional) |

| Solution system control |

Automatic (optional) or manual |

| Fill location |

Side fill, front fill (optional) |

| Chemical injection method |

Direct injection (optional) |

| Chemical eductor |

Stainless steel |

| Chemical eductor capacity (size) |

32 L

8.5 gal. |

| Flow meter size |

5.1 cm

2 in. |

| Suction strainer |

20 mesh |

| Pressure strainer |

50 mesh |

| Boom strainer |

80 mesh |

|

Boom

|

| Boom length options |

27.4, 30.4, 36.5, or 40 m

90, 100, 120, or 132 ft |

| Automatic boom height |

BoomTrac Pro - 5 sensor (optional) |

| Plumbing material |

Stainless steel (polyethylene optional) |

| Boom Material |

Steel or carbon fiber |

| Ground height adjustment |

50 to 245 cm

19.6 to 96.5 in. |

| Breakaway width |

Stainless-steel boom - 3.3 m

10.8 ft, in.

Carbon fiber boom - 3.7 m

12.1 ft |

| Boom sections |

13 sections with boom length - 40 m

132 ft

11 sections with boom length - 36.58 m

120 ft

9 sections with boom length - 30.48 m

100 ft

7 sections with boom length - 27.43 m

90 ft |

| ExactApply™ Nozzle Spacings |

15 or 20 in. |

|

Drivetrain

|

| Type |

Hydrostatic |

| Drive |

Full-time four-wheel drive (4WD) |

| Shifting |

Electrohydraulic |

| Hydraulic reservoir capacity |

98 L

26 gal. |

|

Chassis

|

| Dry compatible |

Yes - 5.7 m3

200 cu ft |

| Front tires |

320/90 R46, 380/90 R46, or 420/80 R46 |

| Rear tires |

320/90 R46, 380/90 R46, or 420/80 R46 |

| Flotation tires |

520/85R38 or 620/70R38 (field installed only) |

| Hydraulic tread adjust |

Standard |

| Wheel tread spacing |

305 to 406 cm

120 to 160 in. |

| Wheel base |

430 cm

169.3 in. |

| Turning radius |

8.7 m

28.5 ft |

| Parking brake |

Spring-engaged, hydraulic-disengaged wet disk pack |

| Primary brakes |

Hydrostatic |

| Ladder raise/lower |

Automatic |

| Total weight with 90-ft boom |

13,475 kg

29,707 lb |

| Total weight with 100-ft boom |

13,550 kg

29,873 lb |

| Total weight with 120-ft boom |

13,805 kg

30,435 lb |

| Total weight with carbon fiber boom |

36.6-m (120-ft) boom - 13,304 kg

29,330 lb

40.2-m (132-ft) boom - 13,359 kg

29,451 lb |

|

Options

|

| Air compressor |

Onboard air (standard) |

| Foam marker capacity |

Air injection foamer - 5.7 L

1.5 gal. |

Accessories and Attachments

12V Pump Kit - SWDEF12VKIT

2.5 gal jug of John Deere Diesel Exhaust Fluid - SWDEF025

20gal Portable Dispensing Unit with lockable, hinged lid - SWDEFPDU20T

275gal tote of John Deere Diesel Exhaust Fluid - SWDEF275

330gal tote of John Deere Diesel Exhaust Fluid - SWDEF330

55gal drum of John Deere Diesel Exhaust Fluid - SWDEF055

60gal Portable Dispensing Unit with lockable, hinged lid - SWDEFPDU60T

110V Pump Kit - SWDEF110VKIT

Fire Extinguisher - TY26852

Shield - Underframe Shields - BKK10017

Cold Weather Radiator Screen kit - BKK10270

Air Intake Snorkel Kit - BKK10276

Front Fill Conversion - BKK10022

Foam Marker System, Air Injection - Single Drop Only - BKK10021

Fence Row Nozzle (Left or Right Side) (Qty. 1) - BKK10289

Direct Injection System with (2) High Volume Pump w/ Pump Rinse and 200 Gallon Chemical Capacity - BKK10305

4 Series Sprayer with direct injection

4 Series Sprayer with direct injection 4 Series Sprayer with direct injection

4 Series Sprayer with direct injectionDirect injection is available for large 4 Series Sprayers (R4030/R4038/R4045) as a field-installed option. As solution tank mixes become more complex, operators need a better way to manage the products they are mixing in helping to reduce the risk of chemical residue. The integrated direct-injection system provides up to 889 L (235 gal.) of additional carrying capacity for raw chemicals and allows injection of up to two separate products directly into the boom (depending on installed configuration).

| Machine | Carrying capacity | Maximum number of chemicals injected |

| R4030/38 model year 2015 and older (SN 10,999 and lower) | 511 L (135 gal.) | Two-one high volume, one low volume |

| R4030/R4038 model year 2016 and newer (SN 11,000 and higher) | 889 L (235 gal.) | Three-two high volume, one low volume |

| R4045 | 889 L (235 gal.) | Three-two high volume, one low volume |

NOTE: Low-volume tanks and pumps must be configured with at least one high-volume tank and pump. High-volume tank and pump can be configured by itself.

The high-volume pump is capable of producing spray rates between 0.15 to 5.92 L/min (0.04 to 1.56 gpm). The low-volume pump can achieve spray rates as low as 0.03 to 1.18 L/min (0.008 to 0.31 gpm).

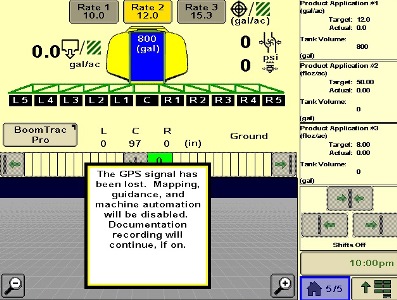

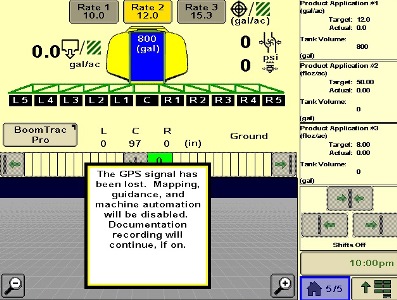

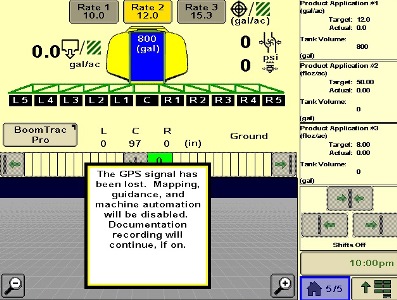

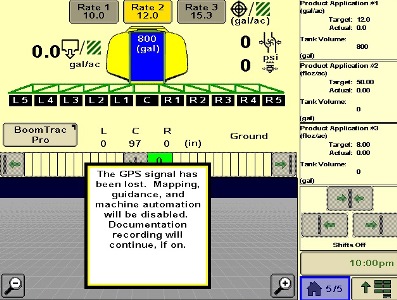

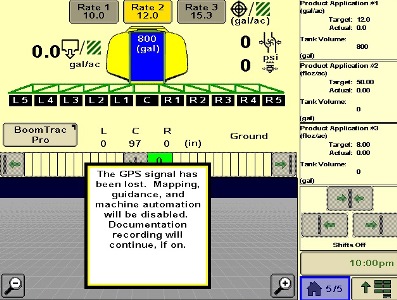

Fully integrated GreenStar™ (GS) Display

GS display can be set up showing direct injection pump information on right-hand side of the screen

GS display can be set up showing direct injection pump information on right-hand side of the screenSince the large 4 Series Sprayers (R4030/R4038/R4045) are designed to be direct-injection ready, the system is fully integrated with the GS 2630 Display. This means less clutter in the cab due to the elimination of multiple displays as everything is controlled by the GS display. Additionally, direct-injection ready means the electrical architecture of the R4030, R4038, and R4045 is designed for plug-and-play installation. Full integration with direct injection means less downtime and more time spraying in the field.

Model year 2017 direct-injection systems (attachments BKK10302, BKK10303, BKK10304, BKK10305) will have pump-rinse functionality added. Pump-rinse functionality can also be added to a current direct-injection system by adding a three-way inlet valve to each DI pump. The three-way valve connects on one port to the chemical tank for normal operation (injection) and to the clean water rinse tank on the other port (for daily pump rinse).

This feature allows for rinse water to be pulled from rinse tank, through the pump head, and out of the boom mixing chamber. This yields the following benefits:

- Automatic rinse system, integrated with pump operating modes, cleans chemical out of pump

- Reduce chemical residual buildup in pump

- Improved maintenance process, while enabling product to be stored in direct-injection tanks between operation

Direct Injection System with (1) Low Volume Pump w/ Pump Rinse and 35 Gallon Chemical Capacity - BKK10302

4 Series Sprayer with direct injection

4 Series Sprayer with direct injection 4 Series Sprayer with direct injection

4 Series Sprayer with direct injectionDirect injection is available for large 4 Series Sprayers (R4030/R4038/R4045) as a field-installed option. As solution tank mixes become more complex, operators need a better way to manage the products they are mixing in helping to reduce the risk of chemical residue. The integrated direct-injection system provides up to 889 L (235 gal.) of additional carrying capacity for raw chemicals and allows injection of up to two separate products directly into the boom (depending on installed configuration).

| Machine | Carrying capacity | Maximum number of chemicals injected |

| R4030/38 model year 2015 and older (SN 10,999 and lower) | 511 L (135 gal.) | Two-one high volume, one low volume |

| R4030/R4038 model year 2016 and newer (SN 11,000 and higher) | 889 L (235 gal.) | Three-two high volume, one low volume |

| R4045 | 889 L (235 gal.) | Three-two high volume, one low volume |

NOTE: Low-volume tanks and pumps must be configured with at least one high-volume tank and pump. High-volume tank and pump can be configured by itself.

The high-volume pump is capable of producing spray rates between 0.15 to 5.92 L/min (0.04 to 1.56 gpm). The low-volume pump can achieve spray rates as low as 0.03 to 1.18 L/min (0.008 to 0.31 gpm).

Fully integrated GreenStar™ (GS) Display

GS display can be set up showing direct injection pump information on right-hand side of the screen

GS display can be set up showing direct injection pump information on right-hand side of the screenSince the large 4 Series Sprayers (R4030/R4038/R4045) are designed to be direct-injection ready, the system is fully integrated with the GS 2630 Display. This means less clutter in the cab due to the elimination of multiple displays as everything is controlled by the GS display. Additionally, direct-injection ready means the electrical architecture of the R4030, R4038, and R4045 is designed for plug-and-play installation. Full integration with direct injection means less downtime and more time spraying in the field.

Model year 2017 direct-injection systems (attachments BKK10302, BKK10303, BKK10304, BKK10305) will have pump-rinse functionality added. Pump-rinse functionality can also be added to a current direct-injection system by adding a three-way inlet valve to each DI pump. The three-way valve connects on one port to the chemical tank for normal operation (injection) and to the clean water rinse tank on the other port (for daily pump rinse).

This feature allows for rinse water to be pulled from rinse tank, through the pump head, and out of the boom mixing chamber. This yields the following benefits:

- Automatic rinse system, integrated with pump operating modes, cleans chemical out of pump

- Reduce chemical residual buildup in pump

- Improved maintenance process, while enabling product to be stored in direct-injection tanks between operation

Direct Injection System with (1) High Volume Pump w/ Pump Rinse and 200 Gallon Chemical Capacity - BKK10304

4 Series Sprayer with direct injection

4 Series Sprayer with direct injection 4 Series Sprayer with direct injection

4 Series Sprayer with direct injectionDirect injection is available for large 4 Series Sprayers (R4030/R4038/R4045) as a field-installed option. As solution tank mixes become more complex, operators need a better way to manage the products they are mixing in helping to reduce the risk of chemical residue. The integrated direct-injection system provides up to 889 L (235 gal.) of additional carrying capacity for raw chemicals and allows injection of up to two separate products directly into the boom (depending on installed configuration).

| Machine | Carrying capacity | Maximum number of chemicals injected |

| R4030/38 model year 2015 and older (SN 10,999 and lower) | 511 L (135 gal.) | Two-one high volume, one low volume |

| R4030/R4038 model year 2016 and newer (SN 11,000 and higher) | 889 L (235 gal.) | Three-two high volume, one low volume |

| R4045 | 889 L (235 gal.) | Three-two high volume, one low volume |

NOTE: Low-volume tanks and pumps must be configured with at least one high-volume tank and pump. High-volume tank and pump can be configured by itself.

The high-volume pump is capable of producing spray rates between 0.15 to 5.92 L/min (0.04 to 1.56 gpm). The low-volume pump can achieve spray rates as low as 0.03 to 1.18 L/min (0.008 to 0.31 gpm).

Fully integrated GreenStar™ (GS) Display

GS display can be set up showing direct injection pump information on right-hand side of the screen

GS display can be set up showing direct injection pump information on right-hand side of the screenSince the large 4 Series Sprayers (R4030/R4038/R4045) are designed to be direct-injection ready, the system is fully integrated with the GS 2630 Display. This means less clutter in the cab due to the elimination of multiple displays as everything is controlled by the GS display. Additionally, direct-injection ready means the electrical architecture of the R4030, R4038, and R4045 is designed for plug-and-play installation. Full integration with direct injection means less downtime and more time spraying in the field.

Model year 2017 direct-injection systems (attachments BKK10302, BKK10303, BKK10304, BKK10305) will have pump-rinse functionality added. Pump-rinse functionality can also be added to a current direct-injection system by adding a three-way inlet valve to each DI pump. The three-way valve connects on one port to the chemical tank for normal operation (injection) and to the clean water rinse tank on the other port (for daily pump rinse).

This feature allows for rinse water to be pulled from rinse tank, through the pump head, and out of the boom mixing chamber. This yields the following benefits:

- Automatic rinse system, integrated with pump operating modes, cleans chemical out of pump

- Reduce chemical residual buildup in pump

- Improved maintenance process, while enabling product to be stored in direct-injection tanks between operation

Direct Injection System with (1) High Volume Pump w/ Pump Rinse and 100 Gallon Chemical Capacity - BKK10303

4 Series Sprayer with direct injection

4 Series Sprayer with direct injection 4 Series Sprayer with direct injection

4 Series Sprayer with direct injectionDirect injection is available for large 4 Series Sprayers (R4030/R4038/R4045) as a field-installed option. As solution tank mixes become more complex, operators need a better way to manage the products they are mixing in helping to reduce the risk of chemical residue. The integrated direct-injection system provides up to 889 L (235 gal.) of additional carrying capacity for raw chemicals and allows injection of up to two separate products directly into the boom (depending on installed configuration).

| Machine | Carrying capacity | Maximum number of chemicals injected |

| R4030/38 model year 2015 and older (SN 10,999 and lower) | 511 L (135 gal.) | Two-one high volume, one low volume |

| R4030/R4038 model year 2016 and newer (SN 11,000 and higher) | 889 L (235 gal.) | Three-two high volume, one low volume |

| R4045 | 889 L (235 gal.) | Three-two high volume, one low volume |

NOTE: Low-volume tanks and pumps must be configured with at least one high-volume tank and pump. High-volume tank and pump can be configured by itself.

The high-volume pump is capable of producing spray rates between 0.15 to 5.92 L/min (0.04 to 1.56 gpm). The low-volume pump can achieve spray rates as low as 0.03 to 1.18 L/min (0.008 to 0.31 gpm).

Fully integrated GreenStar™ (GS) Display

GS display can be set up showing direct injection pump information on right-hand side of the screen

GS display can be set up showing direct injection pump information on right-hand side of the screenSince the large 4 Series Sprayers (R4030/R4038/R4045) are designed to be direct-injection ready, the system is fully integrated with the GS 2630 Display. This means less clutter in the cab due to the elimination of multiple displays as everything is controlled by the GS display. Additionally, direct-injection ready means the electrical architecture of the R4030, R4038, and R4045 is designed for plug-and-play installation. Full integration with direct injection means less downtime and more time spraying in the field.

Model year 2017 direct-injection systems (attachments BKK10302, BKK10303, BKK10304, BKK10305) will have pump-rinse functionality added. Pump-rinse functionality can also be added to a current direct-injection system by adding a three-way inlet valve to each DI pump. The three-way valve connects on one port to the chemical tank for normal operation (injection) and to the clean water rinse tank on the other port (for daily pump rinse).

This feature allows for rinse water to be pulled from rinse tank, through the pump head, and out of the boom mixing chamber. This yields the following benefits:

- Automatic rinse system, integrated with pump operating modes, cleans chemical out of pump

- Reduce chemical residual buildup in pump

- Improved maintenance process, while enabling product to be stored in direct-injection tanks between operation

Direct Injection System Valve Kit for Pump Rinse on Second High Volume Pump - BKK10317

Direct Injection System Valve Kit for Pump Rinse on Low Volume Pump - BKK10318

Direct Injection System Valve Kit for Pump Rinse on First High Volume Pump - BKK10316

Chemical Eductor, Large (Stainless Steel) - BKK10105

BoomTrac Pro 5-Sensor Automatic Boom Leveling System - BKK10019

Auto boom height-sensing system

Auto boom height-sensing systemThe BoomTrac Pro auto boom height-sensing system is designed to help make operators more productive by providing the following advantages:

- Increase application accuracy and efficiency by maintaining a more consistent boom height above the crop; reduce drift and skips

- Reduce operator fatigue since fewer operations to perform

- Minimize the likelihood of boom damage, downtime, and repair costs since fewer chances for boom to contact the ground

The five-sensor system can either be factory-installed or installed by the dealer at a later date. The addition of either BoomTrac option will add wiring harnesses, hydraulic components, hardware, and sensors to the machine.

Boom Air Purge Conversion - BKK10023

90 Foot Boom, SS Custom Plumbing

1 In. Stainless Steel Pipe Wet Plumbing with (80) 5-Position Nozzle Bodies - BKK10079

90 Foot Boom, Poly Custom Plumbing

1 In. Poly Pipe Wet Plumbing with (80) 5-Position Nozzle Bodies - BKK10080

120 Foot Boom, SS Custom Plumbing

1 In. Stainless Steel Pipe Wet Plumbing with (100) 5-Position Nozzle Bodies - BKK10075

120 Foot Boom, Poly Custom Plumbing

1 In. Poly Pipe Wet Plumbing with (100) 5-Position Nozzle Bodies - BKK10076

100 Foot Boom, SS Custom Plumbing

1 In. Stainless Steel Pipe Wet Plumbing with (100) 5-Position Nozzle Bodies - BKK10077

100 Foot Boom, Poly Custom Plumbing

1 In. Poly Pipe Wet Plumbing with (100) 5-Position Nozzle Bodies - BKK10078