Run screen

Run screen

400 and 600 Series Sprayers and Dry Spinner Spreaders utilize the 4600 CommandCenter and SpreadStar controller allowing integrated control with the machine and dry spinner spreader.

The CommandARM© controls, Gen 4 CommandCenter display, and SpreadStar have been updated and tailored to the needs of operators allowing them to see all key functions on one run screen including AutoTrac© assisted steering system, variable rate documentation, field totals, and dry spinner spreader settings.

The Gen4 CommandCenter display allows operators to set up and apply single or dual products, utilizing variable rate map-based prescriptions with John Deere Section Control functionality. Click anywhere on the display to expand and easily adjust information.

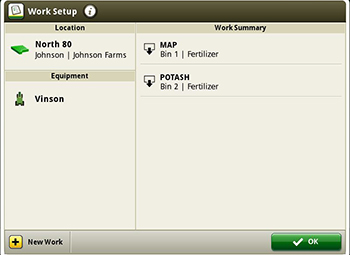

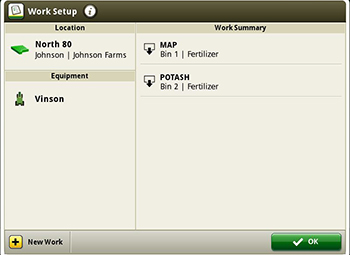

Work setup

Work setup

To prepare for field application, simply press the Setup button in the bottom left corner of the display run page, and it will direct the user to the Work Setup window.

- Select the Location box to setup operator information including farm, field, and Operator information is not required to load and execute a variable-rate prescription.

- Select the Equipment box to do the initial setup of the machine including the number of bins in the dry spinner spreader.

- The Work Summary box shows a link for each bin in the dry spinner spreader. The screenshot above is for a two-bin dry box. Select each one to input or change the name of the product that will be applied. Up to 24 unique names can be entered into the display for various product types such as single product, blended product, or multi-product variable rate. The operator can also choose the target rate for spreading or load a variable-rate prescription.

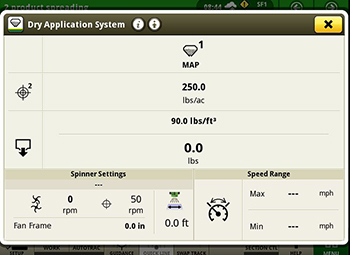

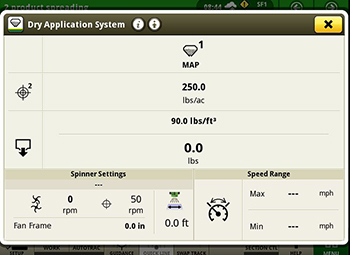

SpreadStar

SpreadStar

Once the Work Setup window is complete, the updated SpreadStar application can then be used to input and setup the following:

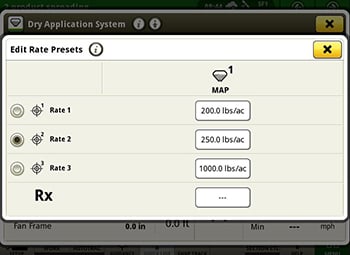

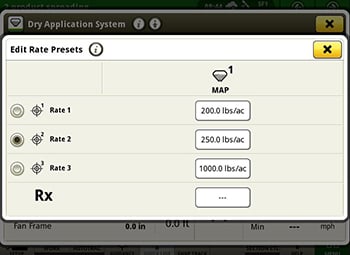

Target spread rate

Target spread rate

Target spread rate ™ selecting the target rate box allows the operator to quickly adjust three different target rates or load a prescription if needed. The target rates can be adjusted when spreading by using the corresponding buttons on the CommandARM.

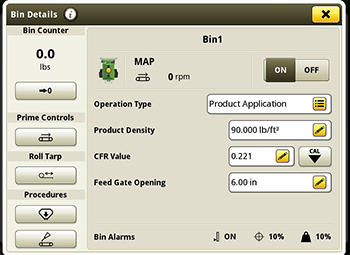

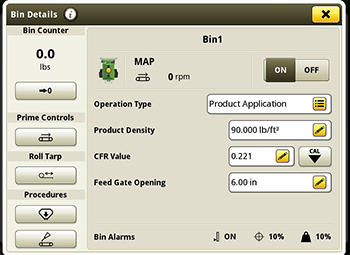

Bin details

Bin details

Product density/product applied ™ selecting either of these areas will take the user to a bin details page where more frequent dry spinner spreader inputs and adjustments are made. For dry spinner spreaders with multiple bins, individual tabs at the top of the screen make it easy to quickly toggle between them.

Features on the bin details page include:

- Bin on/off

- Bin chaining (not shown)

- Product density

- CFR value

- Feed gate opening

- Bin alarms

- Resetting bin counter

- Belt prime

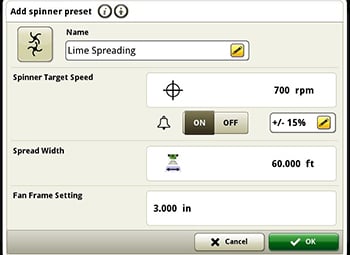

Spinner settings

Spinner settings

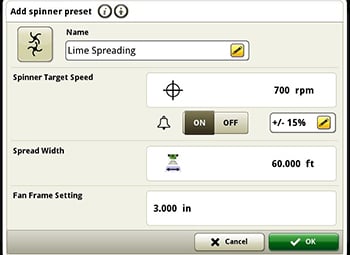

Spinner settings

The last step is to setup the spinner settings by clicking on the spinner settings box in the SpreadStar application. The Add Spinner preset window will come up allowing the operator to create a new preset if they choose.

Preset functions include:

- Spinner target speed

- Spinner target speed alarms

- Spread width

- Fan frame setting

The bin details and spinner settings are saved with the Work Summary details. For example, an operator with a two-bin dry spreader may need to change between a two-product variable rate to a single blend application using bin chaining. When the operator switches back to two-product variable rate, SpreadStar automatically remembers the bin details and spinner settings that were last used with that configuration.

Even with this feature, it is still important to calibrate the dry spinner spreader when changing products to ensure an accurate and consistent spread pattern.