Feature Overview

John Deere 180A

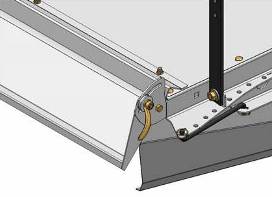

- Heavy-duty knife drive and cutterbar for increased reliability

- Heavy-duty multi-bat reel improves crop flow

- Adjustable reel-cam track to control crop release

- Header index ensures optimum platform speeds

| Cutterbar - Drive | Timed dual knife |

| Cutterbar - Speed | Variable, 1450 - 1900 spm |

| Augers -�Diameter | Single auger: 508 mm / 20 in. |

| Angled-steel conditioner rolls -��Type | Intermeshing steel rolls |

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories

Feature Overview

John Deere 180A

- Heavy-duty knife drive and cutterbar for increased reliability

- Heavy-duty multi-bat reel improves crop flow

- Adjustable reel-cam track to control crop release

- Header index ensures optimum platform speeds

| Cutterbar - Drive | Timed dual knife |

| Cutterbar - Speed | Variable, 1450 - 1900 spm |

| Augers -�Diameter | Single auger: 508 mm / 20 in. |

| Angled-steel conditioner rolls -��Type | Intermeshing steel rolls |

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories