Feature Overview

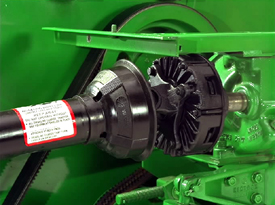

John Deere 972

- The 972 Flail Chopper has a cutting width of 6 ft for good productivity

- Adjustable discharge spout

- Gauge wheels are very easy to change

- Tractor hookup is fast and easy

Feature Overview

John Deere 972

- The 972 Flail Chopper has a cutting width of 6 ft for good productivity

- Adjustable discharge spout

- Gauge wheels are very easy to change

- Tractor hookup is fast and easy

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories