Which rotary cutter is right?

John Deere rotary cutters lead the way with innovative design, superior performance, and proven durability. Valuable features are included such as the Double-Decker™ design and Max Flow cutting chamber, which prevent water and debris from accumulating on the smooth, dome-shaped top deck while the flat bottom deck absorbs the punishment from rocks and stumps.

The top deck stays smooth - no dents, no dings, no holes. The internal supports sandwiched between the top and bottom decks are key to the smooth and structure-free Max Flow cutting chamber, while at the same time provide added strength and durability.

To help promote safe operation, John Deere rotary cutters are equipped with front and rear safety-chain shields. John Deere rotary cutters continue to advance in value with larger, more powerful gearboxes, redesigned blade holders, and updated constant-velocity (CV) drivelines (special to the flex-wing models).

Here are situations when a rotary cutter is needed:

Clipping pastures encourages grass growth, optimizing on valuable pasture acreage.

Cutting grass and stocks helps control insects.

Routine cutting keeps weeds from reseeding.

It is the most cost efficient way to cut roadsides, parks, cemeteries, airport fields, hydro, gas, and telephone easements, and all other types of open properties.

Cutting grass waterways encourages root development and helps prevent erosion.

Knocking down stalks is essential in no-till and minimum-till fields.

Shredding stalks such as cotton, corn, and milo speeds up decomposition.

Clearing out brush is easy.

Use a rotary cutter to control undergrowth and grass in orchards, vineyards, and groves.

John Deere rotary cutters are available in three duty-level categories, three different spindle configurations, four hitch types, and three flex-wing sizes.

Mid-duty

MX models are available in 1.5-m (5-ft), 1.8-m (6-ft), 2.1-m (7-ft), 2.5-m (8-ft), 3.2-m (10-ft), and 4.6-m (15-ft) cut widths.

This duty-level category cuts brush up to 50.8 mm (2 in.) in diameter.

Heavy-duty

HX models are available in 3.2-m (10-ft), 4.2-m (14-ft), 4.6-m (15-ft), and 6.1-m (20-ft) cut widths.

HX6 is available in 1.8-m (6-ft) and the HX7 is available in 2.1-m (7-ft) cut widths; they cut brush up to 101.6 mm (4 in.) in diameter.

Commercial-duty

NOTE: CX models are heavier built to cut at a 101.6mm (4 in.) capacity level more frequently and for longer durations.

Double-Decker™ helps to maintain your cutter clean

Exclusive double-deck in HX6

Exclusive double-deck in HX6

All the MX, HX, and CX Rotary Cutters have the patented Double-Decker© design. The smooth

dome-shaped decks provide easy cleaning and water runs off for longer product life. Deck thickness increases as the size and cutter duty level increases.

Gearcases and blade holders provide better performance

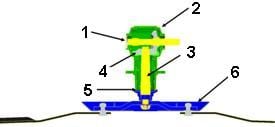

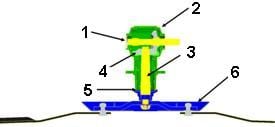

Gearcase and blade holder shown

Gearcase and blade holder shown

The John Deere gearboxes:

- Large seals

- Large housing

- Large output shaft

- Precision forged bevel gears

- Large bearings

- Stump jumper

Re-engineered gearcases and blade holders provide the following:

-

More horsepower

-

Faster blade-tip speed

-

Better performance

-

Quieter operation

-

Increased durability

Front and rear safety chains are standard for increased protection

Front safety chain shield

Front safety chain shield

Rear safety chain shield

Rear safety chain shield

Front and rear safety chain shields are standard equipment. They offer protection yet allow material to pass into the cutting area with minimal obstruction:

- They help deflect thrown material and improve shredding.

Five-year limited gearbox warranty provided on every John Deere rotary cutter

Five-year warranty on all flex-wing gearboxes

Five-year warranty on all flex-wing gearboxes Five-year warranty on all rotary cutter gearboxes

Five-year warranty on all rotary cutter gearboxesJohn Deere is so confident in the reliability of the gearbox, the warranty has been extended. John Deere rotary cutters come with a 5-year limited gearbox warranty.

Deep-cutting chamber provides a better shredding action

HX6 and HX7 deliver a clean cut

HX6 and HX7 deliver a clean cut

The fast blade-tip speed ensures clean cutting and fine shredding of material.

- HX6: 13,623 fpm (69.2 m/sec) and 155 mph

- HX7: 16,061 fpm (81.6 m/sec) and 183 mph

A forward tip adjustment allows the cutter to be tilted forward slightly, so most of the cutting occurs in the front while the shredding action occurs toward the rear:

- Improves cutting job

- Reduces horsepower requirements

The tapered rear opening spreads shredded material across entire width of cut:

- Reduces windrowing

- Leaves an even blanket of mulch

Heavy-duty John Deere-designed gearcases

Heavy-duty gearcase

Heavy-duty gearcase

The heavy-duty gearcase with non-seize self-adjusting slip-clutch driveline is shown at left.

The gearcase horsepower rating is as follows:

- 150 hp (112 kW) continuous

- 210 hp (157 kW) peak

Cast-metal gearcase features:

- Tapered roller bearings and forged gears for longer life (forged gears are stronger because as the gear is heat-forged into shape, the grain of the metal actually changes to follow the outline of the teeth).

- Output shafts are splined, not just keyed, for extra strength.

- Gearcase is solidly mounted to the frame for a long, trouble-free life.

The factory preset, four-plate slip clutch protects the driveline:

The HX6 and HX7 gearcases come standard with a five-year warranty.

What is the best cutter for your job?

NOTE: Only for single spindle and multi-spindle.

John Deere rotary cutters lead the way with innovative design, superior performance, and proven durability. Valuable features such as the Double-Decker© design and Max Flow cutting chamber prevent water and debris from accumulating on the smooth, dome-shaped top deck while the flat bottom deck absorbs the punishment from rocks and stumps.

The top deck stays smooth - no dents, no dings, no holes. The internal supports sandwiched between the top and bottom decks are key to the smooth and structure-free Max Flow cutting chamber, while at the same time provide added strength and durability.

To help promote safe operation, John Deere rotary cutters are equipped with front and rear safety-chain shields. John Deere rotary cutters continue to advance in value with powerful gearboxes, blade holders, and compatibility with a wide range of tractors.

Here are situations when a rotary cutter provides value:

-

Clipping pastures encourages grass growth, optimizing valuable pasture acreage.

-

Cutting grass and stalks helps control insects.

-

Routine cutting keeps weeds from reseeding.

-

It is the most cost efficient way to cut roadsides, parks, cemeteries, airport fields, hydro, gas, and telephone easements, and all other types of open properties.

-

Cutting grass waterways encourages root development and helps prevent erosion.

-

Knocking down stalks such as cotton, corn, or milo speeds up decomposition. This is essential in no-till and minimum-till fields.

-

Clearing out brush.

-

Control undergrowth and grass in orchards, vineyards, and groves.

Decide what model to use based on:

- The size of the area to mow versus the size of the machine ™ the bigger the area to mow, the bigger the mower needs to be in order to be efficient during mowing hours. Similarly, the limitation of a small area will guide operators to use a smaller mower.

- The amount of time and frequency it will be used ™ for longer hours and more frequency, choose a heavier duty machine.

- Tractor compatibility ™ if there is a tractor the operator will be using, look for the tractor compatibility sheet to identify appropriate options.

John Deere rotary cutters are available in two duty-level categories:

-

Mid-duty

-

MX models are available in 1.5-m (5-ft), 1.8-m (6-ft), 2.1-m (7-ft), 2.5-m (8-ft), and 3.2-m (10-ft).

-

This duty-level category cuts brush up to 50.8 mm (2 in.) in diameter.

-

Heavy-duty

NOTE: HX models are heavier built to cut at a 101.6 mm (4 in.) capacity level more frequently and for longer durations.

Five-year limited gearbox warranty provided on every John Deere rotary cutter

Five-year warranty on all flex-wing gearboxes

Five-year warranty on all flex-wing gearboxes

Five-year warranty on all rotary cutter gearboxes

Five-year warranty on all rotary cutter gearboxes

John Deere is so confident in the reliability of the gearbox that rotary cutters come with a 5-year limited gearbox warranty.

There is also 1-year warranty on the complete machine, as well as drivelines and other components.

|

Capacity

|

| Cutting width |

2,134 mm

84 in. |

| Cutting height |

50 to 229 mm

2 to 9 in. |

| Cutting capacity |

101.6 mm

4 in. |

| Cutting chamber Depth |

300 mm

11.8 in. |

|

Tractor compatibility

|

| Tractor PTO HP range |

Minimum 34 kW

45 hp |

| Tractor PTO |

540 rpm |

|

Wheels

|

| Type |

Laminated |

|

Hitch

|

| Category |

2, 3N |

|

Dimensions

|

| Transport width |

2,261 mm

89 in. |

| Deck shape |

Domed |

| Deck type |

Double decker |

| Deck thickness |

Upper

3 (11) mm

0.118 (11) in.

Lower

3.5 (10) mm

0.138 (10) in.

|

| Side skirt thickness |

6 (3) mm

0.25 (3) in. |

| Approx. weight |

625 kg

1,378 lb |

|

Drivelines

|

| Size |

Main

ASAE Category 4

|

| Protection |

Main

Non-seize, slip-clutch driveline

|

|

Gearcases

|

| Number |

1 |

| HP rating |

Center

Continuous 112 kW

150 hp

Peak 152 kW

205 hp

|

|

Blades

|

| Thickness |

13 mm

0.5 in. |

| Width |

102 mm

4 in. |

| Blade tip speed |

540 RPM

4,751 m/min

15,586 fpm

285 km/h

177 mph

|

| Material flow system |

Integrated |

| Holder |

Type

Round stump jumper (single suction) for protection of blades and carrier against obstruction damage

|

|

Shielding

|

| Front |

Chain |

| Rear |

Chain |

Accessories and Attachments

Front Safety Shield - Chain - BP18448

Rear Safety Shield - BW13701

Front safety chain shields

Front safety chain shields Rear safety chain shields

Rear safety chain shieldsCan be used to reduce the hazard of thrown material.

Front chain shields protect the operator, yet still allow uncut material to pass into the cutting chamber with minimal restriction.

Strongly recommended at all times, especially when working near roads or other public areas.