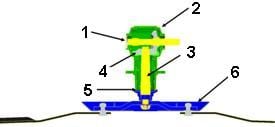

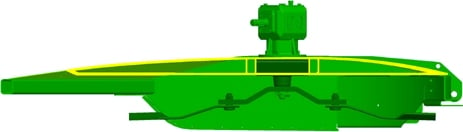

John Deere rotary cutters lead the way with innovative design, superior performance, and proven durability. Valuable features are included such as the Double-Decker™ design and Max Flow cutting chamber, which prevent water and debris from accumulating on the smooth, dome-shaped top deck while the flat bottom deck absorbs the punishment from rocks and stumps.

The top deck stays smooth - no dents, no dings, no holes. The internal supports sandwiched between the top and bottom decks are key to the smooth and structure-free Max Flow cutting chamber, while at the same time provide added strength and durability.

To help promote safe operation, John Deere rotary cutters are equipped with front and rear safety-chain shields. John Deere rotary cutters continue to advance in value with larger, more powerful gearboxes, redesigned blade holders, and updated constant-velocity (CV) drivelines (special to the flex-wing models).

Here are situations when a rotary cutter is needed:

Clipping pastures encourages grass growth, optimizing on valuable pasture acreage.

Cutting grass and stocks helps control insects.

Routine cutting keeps weeds from reseeding.

It is the most cost efficient way to cut roadsides, parks, cemeteries, airport fields, hydro, gas, and telephone easements, and all other types of open properties.

Cutting grass waterways encourages root development and helps prevent erosion.

Knocking down stalks is essential in no-till and minimum-till fields.

Shredding stalks such as cotton, corn, and milo speeds up decomposition.

Clearing out brush is easy.

Use a rotary cutter to control undergrowth and grass in orchards, vineyards, and groves.

John Deere rotary cutters are available in three duty-level categories, three different spindle configurations, four hitch types, and three flex-wing sizes.

Mid-duty

MX models are available in 1.5-m (5-ft), 1.8-m (6-ft), 2.1-m (7-ft), 2.5-m (8-ft), 3.2-m (10-ft), and 4.6-m (15-ft) cut widths.

This duty-level category cuts brush up to 50.8 mm (2 in.) in diameter.

Heavy-duty

HX models are available in 3.2-m (10-ft), 4.2-m (14-ft), 4.6-m (15-ft), and 6.1-m (20-ft) cut widths.

HX6 is available in 1.8-m (6-ft) and the HX7 is available in 2.1-m (7-ft) cut widths; they cut brush up to 101.6 mm (4 in.) in diameter.

Commercial-duty

NOTE: CX models are heavier built to cut at a 101.6mm (4 in.) capacity level more frequently and for longer durations.