The 4200 and 4600 CommandCenter, also known as the Generation 4 CommandCenter, create the primary user interface for 6R, 7R, 8R/8RT, and 9R/9RT/9RX Tractors; F4365 High-Capacity Nutrient Applicator; 4 Series Self-Propelled Sprayers; and S700 Combines. The Generation 4 CommandCenter provides an excellent, user-savvy, efficient operating experience.

Display options

Generation 4 CommandCenter is available in the following configurations:

- 21.3-cm (8.4-in.) display on the 4200 CommandCenter

- 25.4-cm (10-in.) display on the 4600 CommandCenter

For growers wanting to maximize their viewing real estate, the 25.4-cm (10-in.) touchscreen color display is an excellent choice. With the 25.4-cm (10-in.) display, the title bar and all shortcut keys may be viewed at all times, allowing operators to monitor more information at once.

John Deere 4200 CommandCenter

John Deere 4200 CommandCenterA. Next run page

B. Status center

C. Expand shortcut keys

D. Menu

E. Run page

John Deere 4600 CommandCenter

John Deere 4600 CommandCenterA. Next and previous run page

B. Status center

C. Shortcut keys

D. Menu

E. Run page

F. Title bar

John Deere Generation 4 CommandCenter processors

A Generation 4 CommandCenter is made up of a processor and a display. Two processor options are available for the Generation 4 CommandCenter.

4200 CommandCenter 21.3-cm (8.4-in.) display

4200 CommandCenter 21.3-cm (8.4-in.) displayThe 4200 Processor is base equipment and only offered on 6R, 7210R, and 7230R Tractors.

It offers:

- Compatibility with 21.3-cm (8.4-in.) touchscreen display

- One video camera input

- One USB input

- AutoTrac, Data Sync, and Section Control capable (machine-specific activation sold separately)

CommandCenter compatibility

The table below shows the model year of machines equipped with CommandCenter. Upgrade kits are available for 4100 to 4600 for machines that came equipped with a 4100 CommandCenter from the factory. There are no upgrade kits for converting a 4200 to 4600 at this time.

4200 CommandCenter is available starting with model year 2019 6R, 7210R, and 7230R Tractors.

| Vehicles | Model year | 4200 Processor | 4600 Processor |

| John Deere tractors | | | |

| 6R Series (AutoQuad™ transmission/CommandQuad™ transmission) Series | 2019 and newer | Standard | Not applicable |

| 6R (IVT transmission/DirectDrive), 7210R, 7230R Series | 2019 and newer | Standard | Option |

| 7250R, 7270R, 7290R, 7310R Series | 2014 and newer | Not applicable | Standard |

| 8R/8RT Series | Mid-2014 and newer | Not applicable | Standard |

| 9R/9RT/9RX Series | 2015 and newer | Not applicable | Standard |

| John Deere nutrient applicators | | | |

| F4365 Nutrient Applicator | 2017 and newer | Not applicable | Standard |

| John Deere self-propelled sprayers | | | |

| 4 Series Sprayers | 2018 and newer | Not applicable | Standard |

| John Deere combines | | | |

| S-Series Combines | 2018 and newer | Not applicable | Standard |

Expect easier set-up, along with increased operator confidence, thanks to a simple, customizable interface. The improved design of the Generation 4 CommandCenter also aids in an optimal operating experience and maximizes uptime.

Some of the easy-to-use benefits of the Generation 4 CommandCenter include:

- Custom-defined views

- Intelligent warnings

- Context-based help

- Ability to import, export, and delete files

Producers can use a variety of implements with the Generation 4 CommandCenter as it is Agricultural Industry Electronics Foundation (AEF) ISOBUS compliant for manual control of IOSBUS implements (UT) as well as automatic section control (TC-SC) and documentation in ISOXML format (TC-Basic).

Help icon

Help icon Help center main page

Help center main pageAdditionally, application-based help is also available in all locations of the CommandCenter. Simply click on the {i} icon available on the title bar and it will lead directly to more information on the application currently being used.

Context-based help icon

Context-based help icon Context-based help on iTEC™ system main page

Context-based help on iTEC™ system main pageDiagnostic text and information is available for better understanding of whether applications are operating as directed.

Machine monitor

Machine monitor page

Machine monitor pageThe machine monitor application provides the operator instantaneous readings about the status or condition of the machine. Values shown in the machine monitor vary by application, but typically include parameters like engine speed, coolant temperature, and ground speed. The machine monitor supports run page modules in the Layout Manager, allowing the operator to populate specific machine parameters directly to a run page.

NOTE: The machine monitor application replaces part of the universal performance monitor in previous machines.

Work setup shortcut key (far left)

Work setup shortcut key (far left) Work setup

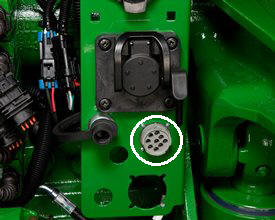

Work setupVideo capability

Tractors with a 4200 CommandCenter are equipped with one video input, and the 4600 CommandCenter Display has four video inputs. The operator has the ability to set a variety of triggers, including reverse, PTO, hitch, and selective control valve (SCV) levers to activate the camera. Once triggered, the image will then appear on the CommandCenter display. The camera (video observation system) is available through JD Parts and Ag and Industrial (A and I) Products.

NOTE: 6R Tractors equipped with a 4600 CommandCenter Display have two video inputs.

Help icon

Help icon 4600 CommandCenter 25.4-cm (10-in.) Display

4600 CommandCenter 25.4-cm (10-in.) DisplayThe 4600 Processor is the premium processor, offered as an option on all 6R*, 7210R, and 7230R Tractors and is standard on 7250R, 7270R, 7290R, 7310R, 8R/8RT, 9R/9RT/9RX Tractors, F4365 Nutrient Applicator, 4 Series Self-Propelled Sprayers, and S700 Combines.

Available features with the premium processor include:

- Compatible with 25.4-cm (10-in.) touchscreen display Four video camera inputs Four USB inputs

- Wireless Data Transfer

- AutoTrac™ guidance capable (machine-specific activation sold separately)

- Machine specific activations including CommandCenter Premium and CommandCenter Automation enables Section Control, Data Sync, RowSense, In-Field Data Sharing, AutoTrac Implement Guidance, AutoTrac Turn Automation, Machine Sync and John Deere Wireless Data Transfer (WDT) (with a JDLink™ Connect subscription)

- Export screenshots and troubleshooting information easily from the display

*Only compatible with Infinitely Variable Transmission (IVT™) and DirectDrive™ transmission

Layout manager

Layout manager selection page

Layout manager selection page Layout manager module build

Layout manager module buildThe Generation 4 CommandCenter features a modular-designed layout manager, so operators can easily create the page views that meet their needs. From the factory, machines are equipped with default run pages. An unlimited number of run pages can be added to the Generation 4 CommandCenter based on operator preference or operational needs. Toggling between run pages is as easy as swiping the screen or using the arrow buttons on the top right portion of the title bar.

Users and access

Users and access allow the owner or manager to lock out certain functions to prevent operators from accessing or changing settings. Lock-out functions are managed with a defined four-digit code.

Lock-out features are available for:

Factory data reset

Hitch

Hydraulic

Transmission

Power take-off (PTO)

FieldCruise™ system

Display

Machine monitor

On-screen help and diagnostic text

There are a number of different ways to get meaningful on-screen help when navigating the Generation 4 CommandCenter. Operators can find the help icon on the shortcut bar on the bottom of every page. This icon gives detailed information on everything from tractor operation to application information. Simply select the help icon and navigate to the information section that is needed.

Work monitor

Work monitor page

Work monitor pageThe work monitor application displays performance information about the task being performed by the machine. The operator is shown averages, totals, and productivity of the machine, such as area worked, average working speed, and fuel usage. The values of the work monitor can be reset by the operator at any time. Specific values of the work monitor can be configured by the operator to be shown on a run page.

NOTE: The work monitor application replaces part of the Universal Performance Monitor in previous machines.

Work setup application

Work setup places the settings needed to properly setup AutoTrac, Documentation, and Section Control in a single location.

Settings include:

- Client, farm, and field

- Crop type

- Machine and implement dimensions

- Variety/hybrid and planting/ seeding rates

- Variable rate prescriptions

- Product and application rates

- Application rates through the implement screens

Work setup can be quickly accessed from a shortcut key or the display menu, allowing operators and managers to quickly review display and machine settings to ensure a job is completed properly.

Flags

Create flags to mark items in the field

Create flags to mark items in the fieldMark areas of the field that need special attention or items that need to be addressed such as rocks, tile lines, or weed pressure. Flags previously recorded on the Gen 4 or GreenStar™ 3 (GS3) 2630 Display can be transferred between displays to ensure each operator is aware of upcoming field obstacles.

Document field boundaries

Manually drive field boundaries with the Generation 4 CommandCenter or import existing boundary information from the GS3 2630 Display or John Deere Operations Center. Gen 4 documentation data can be used to create boundaries from coverage within the John Deere Operations Center.

The display uses a streamlined boundary creation process that generates exterior and interior field boundaries from coverage, simplifying the process and reducing steps. Operators can delete interior boundaries without impacting the exterior boundary or headlands. In addition, operators can chose to turn boundaries off for section control while using them for field locator and documentation.

Headland boundaries can also quickly be generated by simply entering a distance or the number of passes from an exterior boundary.

Boundary creation from coverage

Boundary creation from coverage Headland creation

Headland creationBoundaries can be imported from the following sources:

- John Deere Operations Center

- Directly from a GS3 2630 Display or another Gen 4 Display

- APEX™ software or another farm management information system (FMIS) system that exports in GS3 2630 Display format

Dual-display mode

Dual display

Dual displayGeneration 4 CommandCenter display and GreenStar displays comparison and compatibility

The Generation 4 CommandCenter works in dual-display mode with GreenStar 3 2630 Display, GreenStar 2 1800 Display, and GreenStar 2 2600 Display.

Generation 4 CommandCenter may be configured to run with the following John Deere displays connected at the cornerpost of a John Deere tractor:

- GreenStar 2 1800 Display

- GreenStar 2 2600 Display

- GreenStar 3 2630 Display

- 4640 Universal Display

- 4240 Universal Display

Vehicle applications will always be located on the Gen 4 CommandCenter.

View on-screen help to properly set up the display when in dual-display mode by clicking on the icon (pictured below).