Which rotary cutter is right?

John Deere rotary cutters lead the way with innovative design, superior performance, and proven durability. Valuable features are included such as the Double-Decker© design and Max Flow cutting chamber, which prevent water and debris from accumulating on the smooth, dome-shaped top deck while the flat bottom deck absorbs the punishment from rocks and stumps.

The top deck stays smooth - no dents, no dings, no holes. The internal supports sandwiched between the top and bottom decks are key to the smooth and structure-free Max Flow cutting chamber, while at the same time provide added strength and durability.

To help promote safe operation, John Deere rotary cutters are equipped with front and rear safety-chain shields. John Deere rotary cutters continue to advance in value with larger, more powerful gearboxes, redesigned blade holders, and updated constant-velocity (CV) drivelines (special to the flex-wing models).

Here are situations when a rotary cutter is needed:

-

Clipping pastures encourages grass growth, optimizing on valuable pasture acreage.

-

Cutting grass and stalks helps control insects.

-

Routine cutting keeps weeds from reseeding.

-

It is the most cost efficient way to cut roadsides, parks, cemeteries, airport fields, hydro, gas, and telephone easements, and all other types of open properties.

-

Cutting grass waterways encourages root development and helps prevent erosion.

-

Knocking down stalks is essential in no-till and minimum-till fields.

-

Shredding stalks such as cotton, corn, and milo speeds up decomposition.

-

Clearing out brush is easy.

-

Use a rotary cutter to control undergrowth and grass in orchards, vineyards, and groves.

John Deere rotary cutters are available in three duty-level categories, three different spindle configurations, four hitch types, and three flex-wing sizes.

-

Mid-duty

-

MX models are available in 1.5-m (5-ft), 1.8-m (6-ft), 2.1-m (7-ft), 2.5-m (8-ft), 3.2-m (10-ft), and 4.6-m (15-ft) cut widths.

-

This duty-level category cuts brush up to 50.8 mm (2 in.) in diameter.

-

Heavy-duty

-

HX models are available in 3.2-m (10-ft), 4.2-m (14-ft), 4.6-m (15-ft), and 6.1-m (20-ft) cut widths.

-

HX6 is available in 1.8-m (6-ft) and the HX7 is available in 2.1-m (7-ft) cut widths; they cut brush up to 101.6 mm (4 in.) in diameter.

-

Commercial-duty

NOTE: CX models are heavier built to cut at a 101.6mm (4 in.) capacity level more frequently and for longer durations.

CX15 and CX20 product values

CX15 and CX20 product values

CX15 and CX20 product values

100 percent factory assembled

- Category 5, multi-profile driveline

- Protected front chain shields

- Category 5, star-profile wing drivelines

- Smooth, dome-shaped Double-Decker© design

- Spring-loaded wing arms

- Air bag and shock-absorber suspension

- Continuous, greaseable forged-wing hinges

- Cast hitch, best turn radius

- Hydraulic parking system

- Ball-and-clevis hitch connection

CX20 equipped with three deck rings

CX20 with three standard deck rings

CX20 with three standard deck rings

The CX20 is equipped with three deck rings, which are welded to the underside of the deck, just inside the outer circumference of blade travel. The deck rings help to limit the upward deflection of blades, when blades encounter immovable objects such as stumps and set-fast rocks.

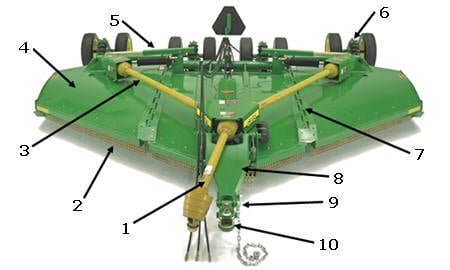

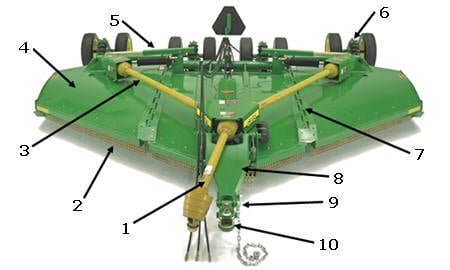

Gearcases and blade holders provide better performance

Gearcase and blade holder shown

Gearcase and blade holder shown

The John Deere gearboxes:

- Large seals

- Large housing

- Large output shaft

- Precision forged bevel gears

- Large bearings

- Stump jumper

Re-engineered gearcases and blade holders provide the following:

-

More horsepower

-

Faster blade-tip speed

-

Better performance

-

Quieter operation

-

Increased durability

Flex-wing constant-velocity (CV) driveline is easy to attach

CV driveline

CV driveline

Benefits of the CV driveline:

-

Lock-slide collar, included on all John Deere’s drivelines, helps the attachment to the tractor using your hands on the driveline and not on the collar.

-

Professional seals on the cross kits allow for a lubrication interval up to 50 hours.

-

Grease zerks in the cap cross kits provide easy access for field lubrication.

-

Large, dimpled floating disks reduce wear and improve the grease retention.

-

Precision spherical ball-and-socket bearings distribute loading evenly and provide a long life and high performance.

A lightweight driveline with a lock-slide collar makes it fast and easy to attach.

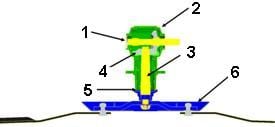

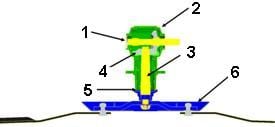

Four larger, more durable gearcases

Cross-section of gearcase

Cross-section of gearcase

The HX20 and CX20 Flex-Wing Rotary Cutters utilize a four-gearcase design. This is far superior to a three-gearcase design because the wing drivelines are able to operate at a range of angles, from 22 degrees down and up to 45 degrees. The wings fold up to 90 degrees for transport-lock purposes.

Additionally, the transfer of power from the tractor is dedicated to the transfer gearcase while the cutting is handled by three separate and properly sized individual gearcases. This results in superior drivetrain reliability and durability:

- HX20 uses a 250 continuous hp and 300 peak hp splitter gearcase, and 150 continuous hp and 205 peak hp center and outer gearcases.

- CX20 uses a 250 continuous hp and 300 peak hp splitter gearcase, and 150 continuous hp and 216 peak hp center and outer gearcases.

Large, tapered roller bearings and forged gears provide a long trouble-free operating life. Horizontal shafts in all gearcases are 1.5-cm (1-3/4 in.) in diameter to resist torque spikes. Output shafts have a tapered spline for a tight connection with blade holders.

Gearcases are backed up by a five-year warranty.

CX ground-control suspension

Exclusive ground-control suspension

Exclusive ground-control suspension

CX Series Flex-Wing Rotary Cutters feature ground-control suspension, which is unique in the industry.

This suspension includes a heavy-duty axle with six wheels (five-wheel and three-wheel assemblies for the CX15 3.1-m [10-ft] model) and air springs with shock absorbers on all four-wheel assemblies.

Shock absorbing

Shock absorbing

Shock absorbers provide a smooth ride for road travel and for hard and rough pastures, roadsides, etc. The shock-cushioning ability of the CX suspension is in a class by itself and contributes greatly to long, trouble-free operation of the machine.

Center-section air springs typically carry 90 psi of air pressure. Wing-section air springs typically carry 60 psi of air pressure.

All of the CX models are also available with springs and shock absorbers.

Continuous and greaseable wing-frame hinges

HX20 hinges

HX20 hinges

CX20 hinges

CX20 hinges

Center sections and wing sections are connected via 2.5-cm (1-in.) diameter continuous hinge pins. Hinge bushings are constructed of 15.2-cm (6-in.) long forged-steel segments and are greaseable to prevent hinge pins from seizing.

- The HX20 uses nine hinge bushing segments per side.

- The CX20 uses 16 hinge bushing segments per side, for a continuous hinge (front to back), providing superior resistance to the wear and tear caused by commercial usage.

Tight turns can be performed

Tight turning radius (CX15 shown)

Tight turning radius (CX15 shown)

Hitches have a narrow profile and are 57.2 cm (22.5 in.) wide to allow a very tight turning radius, even when the tractor is equipped with dual wheels.

Transport lock offers a safe wing-up position

Transport lock ensures wings stay secured

Transport lock ensures wings stay secured

A transport lock flips over the lift cylinder for backup to the hydraulics when transporting or servicing the cutter.

A wing lock is provided for additional safety during transporting or servicing. Additionally, the wing locks are spring-loaded so they can unfold against gravity on slopes up to five degrees.

Hydraulic height leveling system makes cutter leveling easy and safe

A manual-implement jack is in base equipment

A manual-implement jack is in base equipment

The HX15, CX15, HX20, and CX20 come standard with an industry-exclusive hydraulically-operated height leveling system with a swing-away parking stand that makes raising and lowering the cutter easy and safe. In addition, a manual-implement jack is in base equipment, so hitch leveling can also be adjusted without hydraulics. With this addition, the cutter will remain in the same position for long periods of time.

Five-year limited gearbox warranty provided on every John Deere rotary cutter

Five-year warranty on all flex-wing gearboxes

Five-year warranty on all flex-wing gearboxes

Five-year warranty on all rotary cutter gearboxes

Five-year warranty on all rotary cutter gearboxes

John Deere is so confident in the reliability of the gearbox, the warranty has been extended. John Deere rotary cutters come with a 5-year limited gearbox warranty.

CX ground-control suspension

Exclusive ground-control suspension

Exclusive ground-control suspension

CX Series Flex-Wing Rotary Cutters feature ground-control suspension, which is unique in the industry.

This suspension includes a heavy-duty axle with six wheels (five-wheel and three-wheel assemblies for the CX15 3.1-m [10-ft] model) and air springs with shock absorbers on all four-wheel assemblies.

Shock absorbing

Shock absorbing

Shock absorbers provide a smooth ride for road travel and for hard and rough pastures, roadsides, etc. The shock-cushioning ability of the CX suspension is in a class by itself and contributes greatly to long, trouble-free operation of the machine.

Center-section air springs typically carry 90 psi of air pressure. Wing-section air springs typically carry 60 psi of air pressure.

All of the CX models are also available with springs and shock absorbers.

|

Capacity

|

| Cutting width |

6,096 mm

240 in. |

| Cutting height |

For clearance over terraces 25-406 mm

1-16 in. |

| Cutting capacity (diameter) |

101.6 mm

4 in. |

| Cutting chamber depth |

267 mm

10.5 in. |

|

Tractor compatibility

|

| Tractor PTO HP range |

55.92 kW

75 hp |

| Tractor PTO |

1,000 rpm |

| Static Vert Drawbar Load Rating |

1,200 kg

2,640 lb |

|

Blades

|

| Type |

Suction or dual |

|

Hitch

|

| Hitch width |

For tight turn capability 570 mm

22.5 in. |

| Jackstand |

Stays vertical while raising or lowering |

|

Dimensions

|

| Transport width |

At wing wheels 3,400 mm

134 in. |

| Overall width |

6,250 mm

246 in. |

| Overall length |

5,760 mm

227 in. |

| Deck shape |

Easy clean dome-shaped top deck |

| Deck type |

Double-decker for superior strength |

| Deck thickness |

Upper

3.5 (10) mm

.138 (10) in.

Lower

3.5 (10) mm

.138 (10) in.

|

| Shirt thickness |

6 mm

.25 in. |

| Hinges |

Intermittent cast steel segments - greaseable; single 1-in. (2.5-cm) diameter full-length hinge pin |

| Approx. weight |

3,350 kg

7,350 lb |

|

Drivelines

|

| Size |

Main

CV ASAE Category 5 splined telescoping profiles

Connecting

ASAE Category 5 splined telescoping profiles

|

| Protection |

Main

No-seize, slip-clutch driveline

Connecting

No-seize, slip-clutch driveline

|

|

Gearcases

|

| Number |

4 |

| HP rating |

Transfer

186 continuous / 224 peak kW

250 continuous / 300 peak hp

Center

112 continuous / 161 peak kW

150 continuous / 216 peak hp

Outer

112 continuous / 161 peak kW

150 continuous / 216 peak hp

|

|

Blades

|

| Thickness |

13 mm

.5 in. |

| Width |

102 mm

4 in. |

| Overlap |

152 mm

6 in. |

| Blade rotation |

CW, CCW, CCW |

| Blade tip speed |

1000 RPM

Wing 4,988 (299 km/h) m/min

16,364 (186 mph) fpm

Center 4,974 (298 km/h) m/min

16,319 (185 mph) fpm

|

| Material flow system |

Smooth, obstruction free Max Flow cutting chamber for a clean cut and no windrows |

| Blade holder |

Type

Bar or stump jumper with standard deck rings

|

|

Hydraulics

|

| Wing lift |

Standard, includes spring assist unfolding |

| Wing flex |

90 up, 22 down degree (angle) |

|

Wheels

|

| Suspension |

Air cushion with shock absorbers on all 4 wheels standard |

| Row width adjustment |

Yes |

| Wing-leveling adjustment |

Easy adjust turnbuckle with bearing |

|

Shielding

|

| Front |

Chain |

| Rear |

Chain |

|

Warranty

|

| w |

w |

Accessories and Attachments

Standard Driveline with Clutch and Lick-Slide Collar - 1000 RPM 1-3/4 Power Take-Off (PTO) - BP18398

Standard Driveline with Clutch and Lock-Slide Collar - 1000 RPM 1-3/8 Power Take-Off (PTO) - BP18397

Constant Velocity with Lock-Slide Collar Driveline, Category 5, 1000 RPM - 34.925 mm (1 3/8 in.) - BP18400

CV driveline

CV drivelineBenefits of the CV driveline include:

- Lock-slide collar, included on all John Deere drivelines, helps during the attachment to the tractor allowing the operator to keep their hands on the driveline and not on the collar.

- Professional seals on the cross kits allow for a lubrication interval of up to 50 hours.

- Grease zerks in the cap cross kits provide easy access for field lubrication.

- Large, dimpled floating disks reduce wear and improve the grease retention.

- Precision spherical ball-and-socket bearings distribute loading evenly and provide a long life and high performance.

A lightweight driveline with a lock-slide collar makes the tractor to cutter connection faster and easier.

Constant Velocity with Lock-Slide Collar Driveline, Category 5, 1000 RPM - 44.45 mm (1 3/4 in.) - BP18401

CV driveline

CV drivelineBenefits of the CV driveline include:

- Lock-slide collar, included on all John Deere drivelines, helps during the attachment to the tractor allowing the operator to keep their hands on the driveline and not on the collar.

- Professional seals on the cross kits allow for a lubrication interval of up to 50 hours.

- Grease zerks in the cap cross kits provide easy access for field lubrication.

- Large, dimpled floating disks reduce wear and improve the grease retention.

- Precision spherical ball-and-socket bearings distribute loading evenly and provide a long life and high performance.

A lightweight driveline with a lock-slide collar makes the tractor to cutter connection faster and easier.

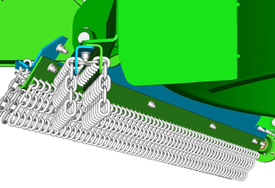

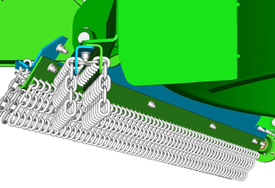

Front Safety Shield - Second Row Chain - BW15672

Second-row chain shields

Second-row chain shieldsThese second-row chain shields take the place of double-row chain shields by making it possible to add on the second row instead of replacing the single row with a double row. All newly ordered and existing flex-wing rotary cutters built after 01 June 2005 can now be converted to double-row shields.

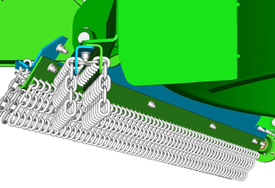

Rear Safety Shield - Second Row Chain - BW15673

Second-row chain shields

Second-row chain shieldsThese second-row chain shields take the place of double-row chain shields by making it possible to add on the second row instead of replacing the single row with a double row. All newly ordered and existing flex-wing rotary cutters built after 01 June 2005 can now be converted to double-row shields.

Dual Wing Wheel Spindles and Hubs - BW14522

Dual wing wheel spindles and hubs (5 bolt)

Dual wing wheel spindles and hubs (5 bolt)

26" x 9" x 14.5" 24 PR "Fat Boy" Severe Duty

Ag Tire and Wheel - AW34779

'Fat Boy' severe-duty agricultural tire

'Fat Boy' severe-duty agricultural tireThese larger tires provide a larger footprint with added flotation for a smoother ride and greater durability for on and off road travel.