Feature Overview

John Deere 725D

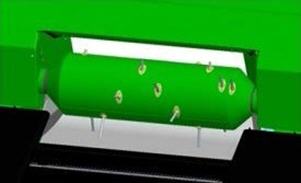

- Hydrafloat™ allows the operator to match changing field conditions

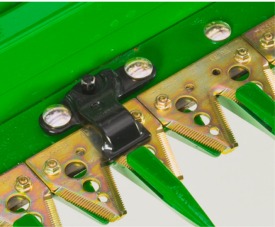

- Double-cut knife system produces a cleaner cut

- Dual-knife drive system is timed

- Cutterbar is closer to the ground

| Cutterbar length | 7.8 m / 25.5 ft |

| Pickup reel operating speeds | 6-54 rpm / 137.2-cm (54-in.) reel: 5-44 rpm |

| Draper belts speed control | Hydraulic from cab |

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories

Feature Overview

John Deere 725D

- Hydrafloat™ allows the operator to match changing field conditions

- Double-cut knife system produces a cleaner cut

- Dual-knife drive system is timed

- Cutterbar is closer to the ground

| Cutterbar length | 7.8 m / 25.5 ft |

| Pickup reel operating speeds | 6-54 rpm / 137.2-cm (54-in.) reel: 5-44 rpm |

| Draper belts speed control | Hydraulic from cab |

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories