Saw blades with changeable segments

Saw blades with changeable segments

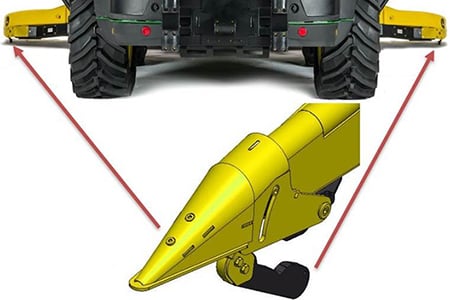

The saw blades of John Deere rotary crop headers cut quickly and thoroughly at a high speed of rotation. As the fast-turning blades cut the full width, crops can be harvested regardless of the row spacing. Thanks to this row-independent harvesting technology, the field can be worked from any side, which is particularly important for down crop.

The fast-turning saw blades allow crops with a lot of weeds to be harvested easily. Besides maize, a wide range of crops such as sorghum, whole crop silage, oilseed, canola, pampas grass, and miscanthus can be harvested.

Key features:

- Fast turning saw blades can cut in difficult harvesting conditions to give the operator increased uptime.

- Headers can be used in various stemmed crops and there is no need for extra headers, which saves on the cost of operation.